A kind of macromonomer and the method for preparing polycarboxylate water reducer with it

A technology of large monomer and water reducer, which is applied in the field of polycarboxylate water reducer, can solve the problems of slow technology update, few types of large monomer, unfavorable development, etc., and achieve low cost, outstanding steric hindrance, and maintenance good collapsibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The application discloses a method for preparing a large order, which comprises the following steps:

[0049] Step 1: Preparation of prepolymer

[0050] Add initiator vinyl glycol ether 10 moles (880g) in reactor, catalyst sodium hydride 2.77g (0.09% of material total amount) mix; Add 50 moles (2200g) of oxyethane again, the Internally adjust the temperature to 110°C for ring-opening polymerization. The pressure in the reactor is controlled at 0-0.45MPa until the pressure in the reactor is constant and then stabilizes for 15-30 minutes. Cool down to 65-80°C to remove unreacted ethylene oxide. ; Obtaining number average molecular weight is the prepolymer of 308;

[0051] Step 2: Preparation of Macromonomer

[0052] Take 1 mole (308g) of the prepolymer, add 2.68g (ie 2.96g-0.28g) of catalyst sodium hydride according to 0.09% of the supplementary material amount; add 15 moles (660g) of ethylene oxide, and join with the initiator The number of moles of ethylene oxide in ...

Embodiment 1~13

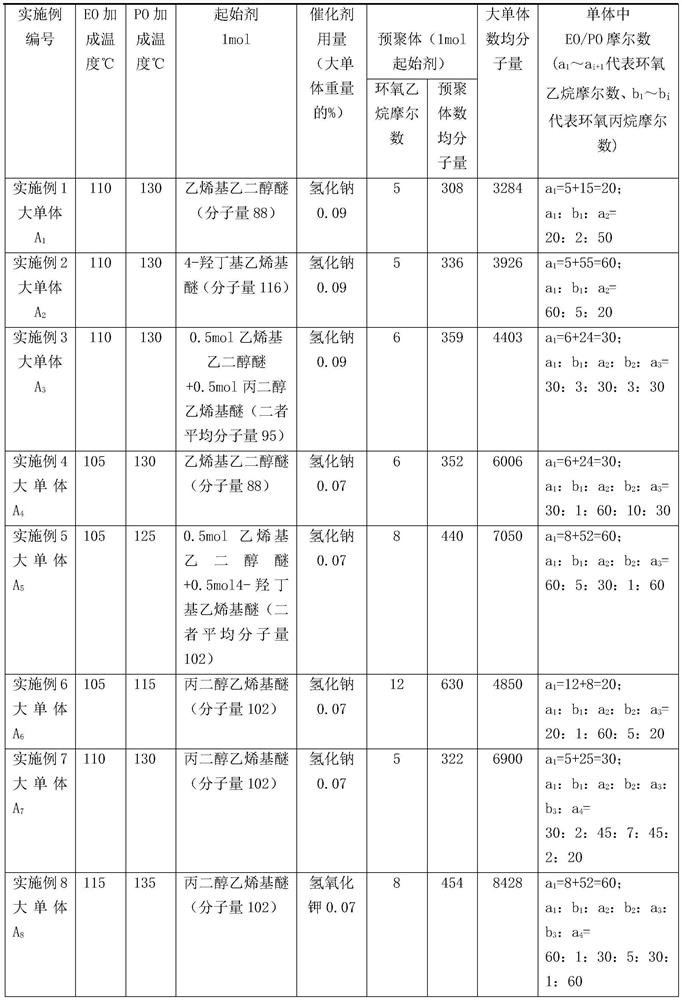

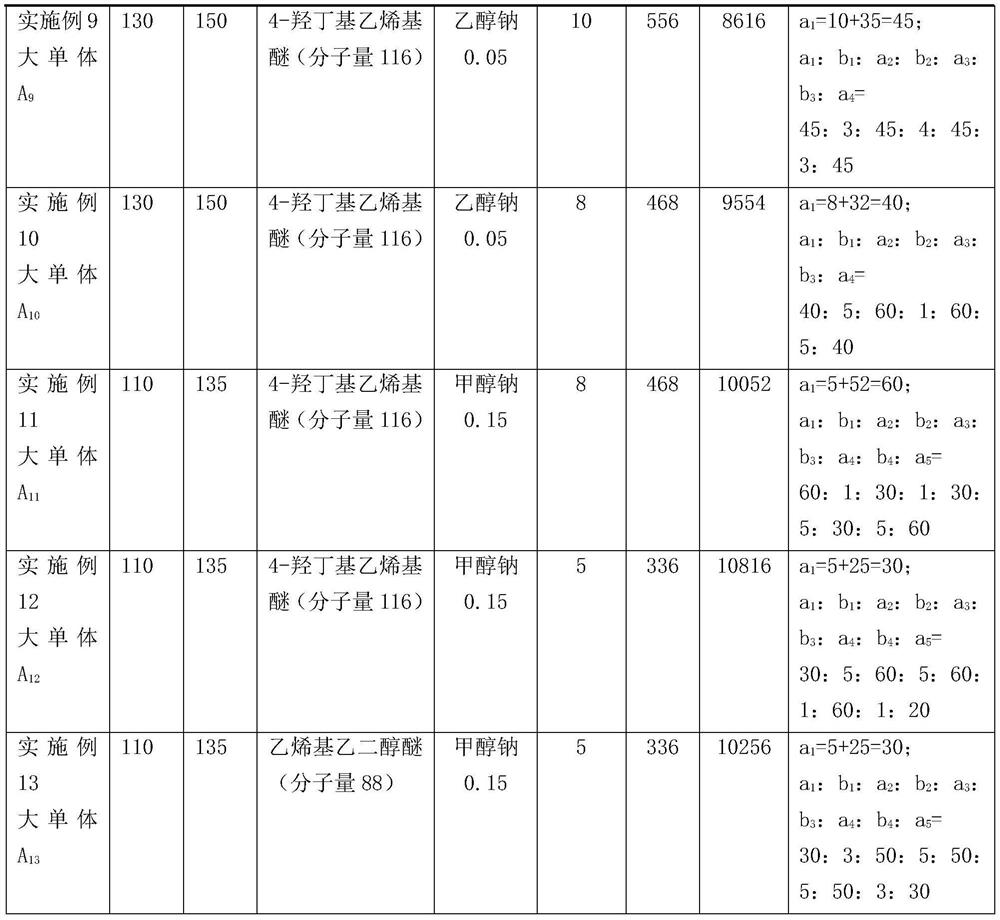

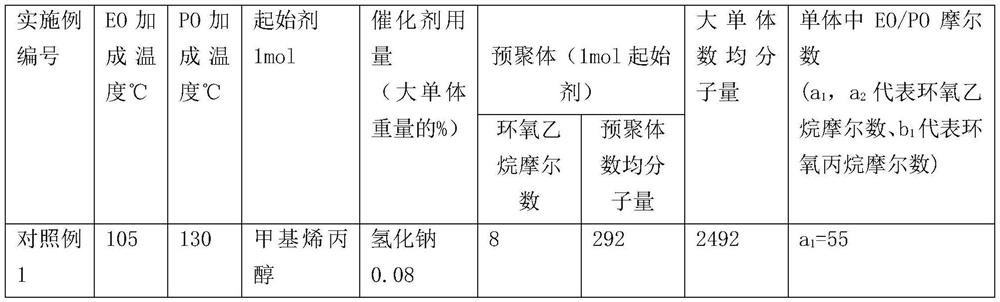

[0059] Embodiments 1 to 13 are the process control conditions for preparing macromonomers (see Table 1)

[0060] Table 1:

[0061]

[0062]

[0063] In the present invention, when the number-average molecular weight of the macromonomer exceeds 9554, it can be realized in the existing industry, but there is a decrease in production efficiency, an increase in viscosity, and a corresponding increase in cost, which has no practical significance in application.

Embodiment J

[0068] Embodiment JS_1~JS_13

[0069] This group of examples is an example of the method of preparing polycarboxylate water reducer with macromonomer in the present invention (free radical copolymerization reaction in redox system).

[0070] The principle of synthesizing polycarboxylate superplasticizer by oxidation-reduction system is to generate free radicals through oxidation-reduction reaction. First add oxidant substances to the system, and then drop the reducing agent to undergo oxidation-reduction reaction with the oxidant in the solution, and generate free radicals to initiate monomer polymerization. Synthetic water reducer.

[0071] The application discloses a method for preparing a polycarboxylate water reducer using a macromonomer, which comprises the following steps:

[0072] Add a part of water into the reaction kettle, add the macromonomer in the example, stir and dissolve; add the aqueous solution of b dropwise while adding the oxidant, the dropping time is 24-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com