Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Good steric hindrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

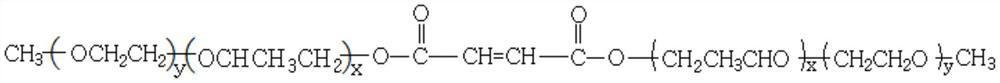

Quadripolymer dispersant and preparation method thereof

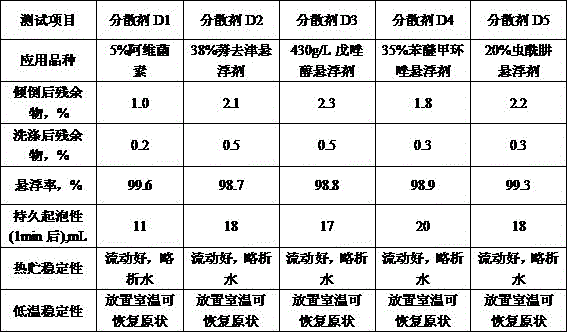

ActiveCN104086714AReduce usageImprove adsorption capacity(Hydroxyethyl)methacrylateSuspending Agents

The invention belongs to the field of polymeric dispersants and specifically relates to a quadripolymer dispersant and a preparation method thereof. The dispersant is formed by copolymerizing 30wt%-60wt% of unsaturated polyether, 10wt%-40wt% of hydroxyethyl methacrylate, 5wt%-15wt% of styrene and 5wt%-15wt% of sodium styrenesulfonate, based on 100% in total. The number-average relative molecular weight of the copolymer is 5000-50000; the dispersant can be widely applied to a formula of suspending agents of insecticides, herbicides and fungicides.

Owner:中化化工科学技术研究总院有限公司 +1

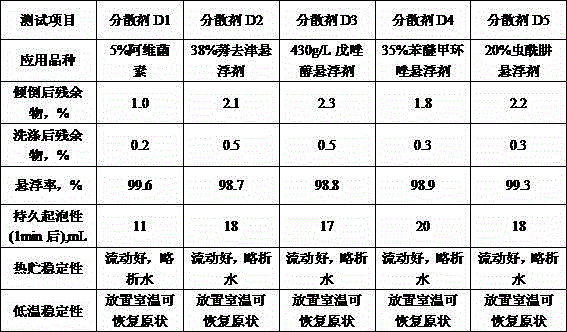

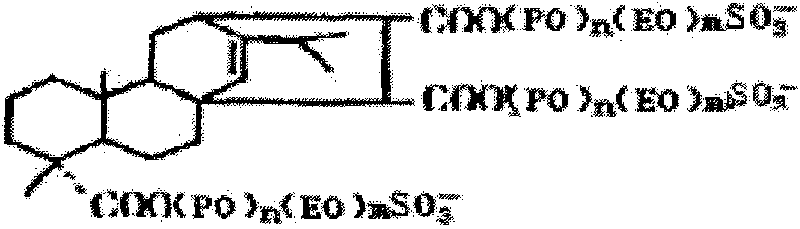

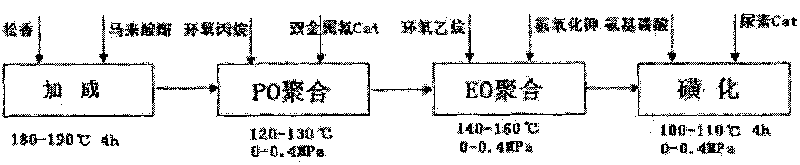

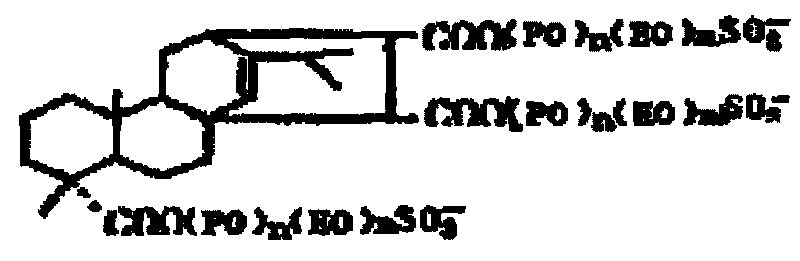

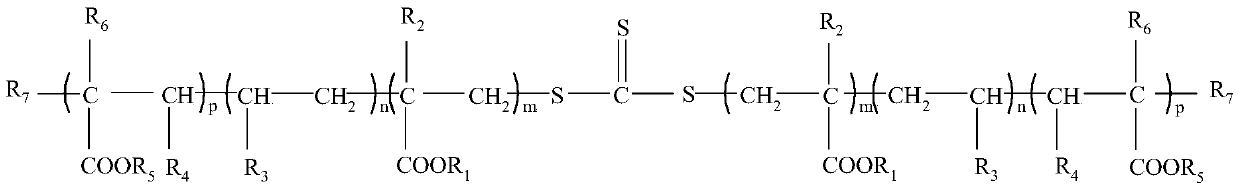

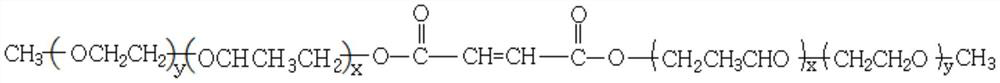

Gemini-like rosin segmented polyether sulfonate, preparation method and application thereof

InactiveCN101712754AEasy to increase thicknessIncreasing the thicknessBiocideTransportation and packagingDispersityFiltration

The invention discloses a Gemini-like rosin segmented polyether sulfonate, a preparation method thereof and application thereof. The preparation method comprises the following steps: sequentially polymerizing a maleic rosin activated monomer with epoxypropane and oxirane in molar ratios to form a segmented copolymer, taking carbamide as a catalyst, sulfonating the carbamide with an aminosulfonic acid in a molar ratio of 1:0.8-2, dissolving the reaction product with a low-molecular weight and low-viscosity alcohol so as to assist filtration, removing the low-molecular weight alcohol, if necessary, replacing a system ammonium with an alkali to release ammonia gas, and forming a liquefied compound of the sulfonate with good dispersity, emulsibility and stability. The Gemini-like rosin segmented polyether sulfonate of the invention can be applied to a pesticide emulsion in water, a suspension agent in water, a suspension agent in oil, a suspending emulsion, a suspending seed coating and other preparations in which the water is used as a continuous phase, and has the advantages of low production cost, practical and feasible process, environmental protection, no pollution, good application performance and the like.

Owner:南京擎宇化工研究有限公司 +1

Polycarboxylic acid water reducing agent used for polyether with molecular weight of 1200 and preparation method of polycarboxylic acid water reducing agent

The invention provides a polycarboxylic acid water reducing agent used for a polyether with a molecular weight of 1200 and a preparation method of the polycarboxylic acid water reducing agent. The polycarboxylic acid water reducing agent comprises the following components in parts by weight: 310-330 parts of a polyether macromonomer with a molecular weight of 1200, 4-14 parts of acrylic acid, 2-9parts of a carboxylate monomer, 2-5 parts of a fluoro functional monomer, 0.9-1.8 parts of hydrogen peroxide, 4-10 parts of a flexible chain monomer, 0.32-0.5 part of a reducing agent, 0.3-0.7 part ofa chain transfer agent, 6-10 parts of a neutralizing agent, and the balance water, wherein a total mass is 1000 parts, and after preparation is performed, a mass fraction of a finished product is 40%, and an acid-ether ratio is 2.7-3.3. The method is performed according to the following steps: 1, material addition for the first time; 2, addition of the hydrogen peroxide; 3, addition of a solutionA and a solution B; and 4, preparation of the finished product. The polycarboxylic acid water reducing agent and method provided by the invention adopt the polyether monomer with the molecular weightof 1200 as a raw material to obtain a suitable side-chain length which can be stretched in the environment, and the problem of weaken steric hindrance brought by a short side chain is compensated.

Owner:HUBEI UNIV OF TECH

High-adaptability mud-resistant water reducing agent and preparation method thereof

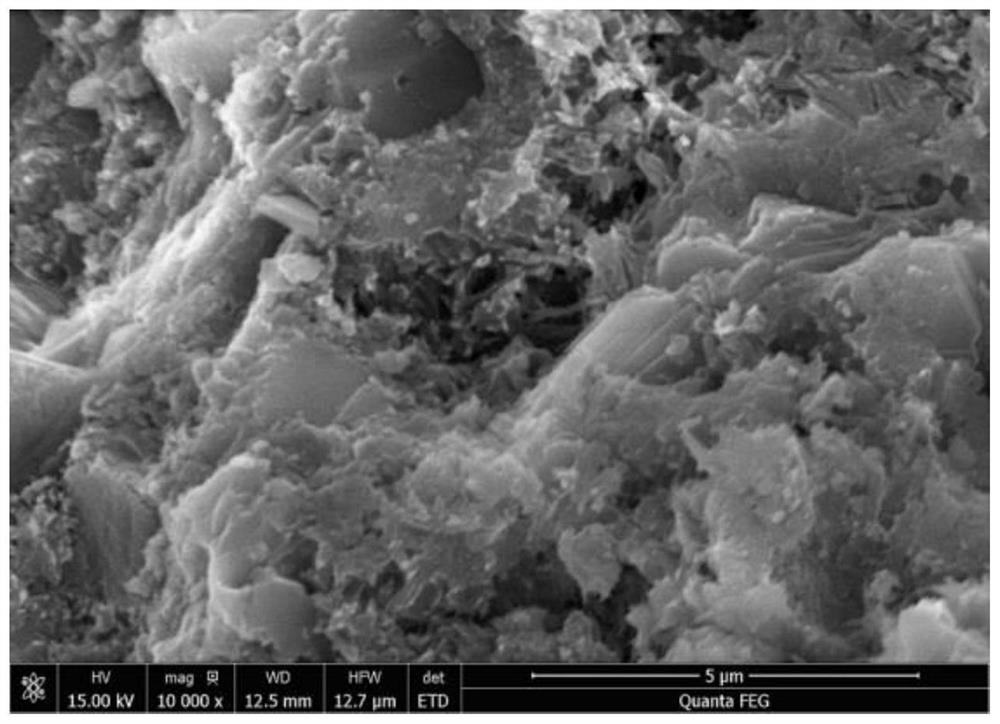

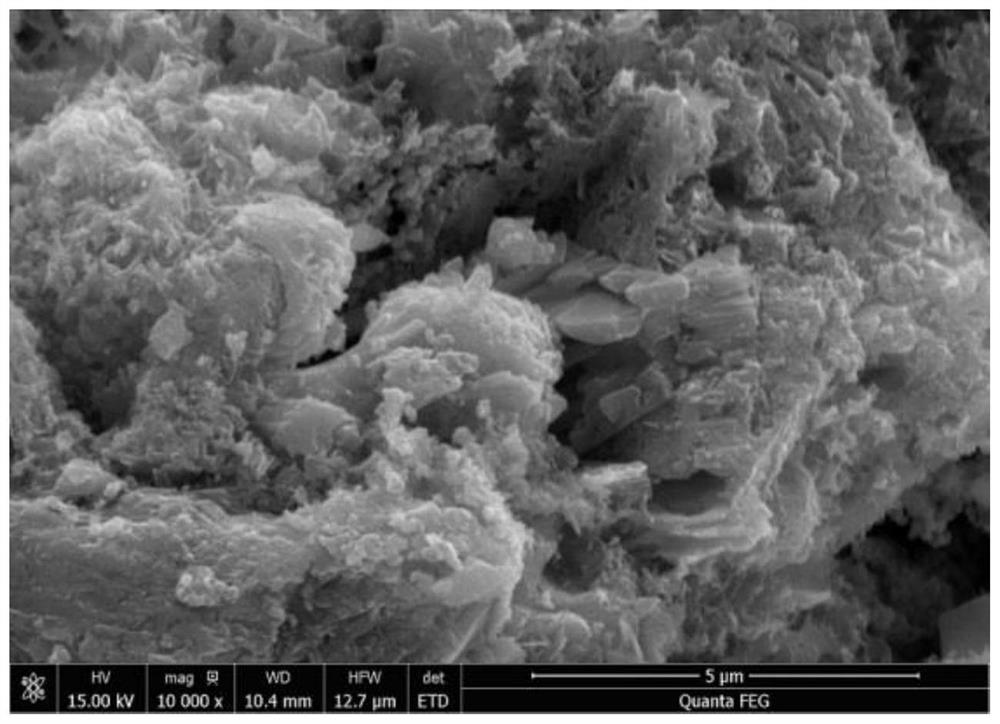

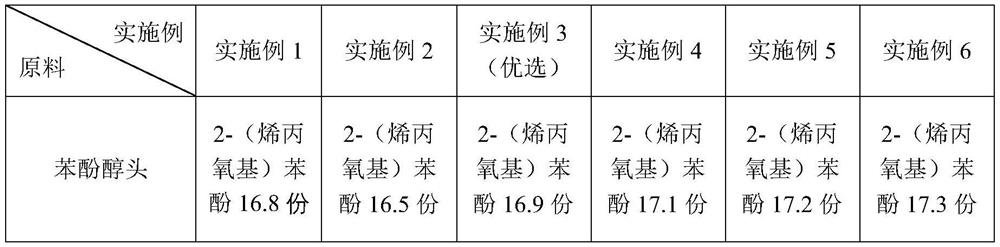

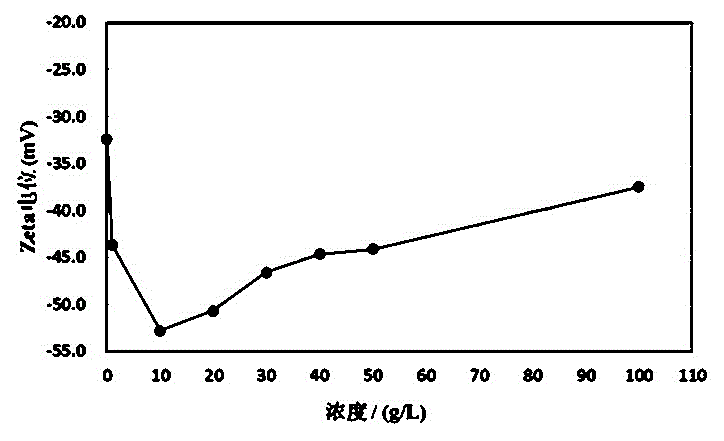

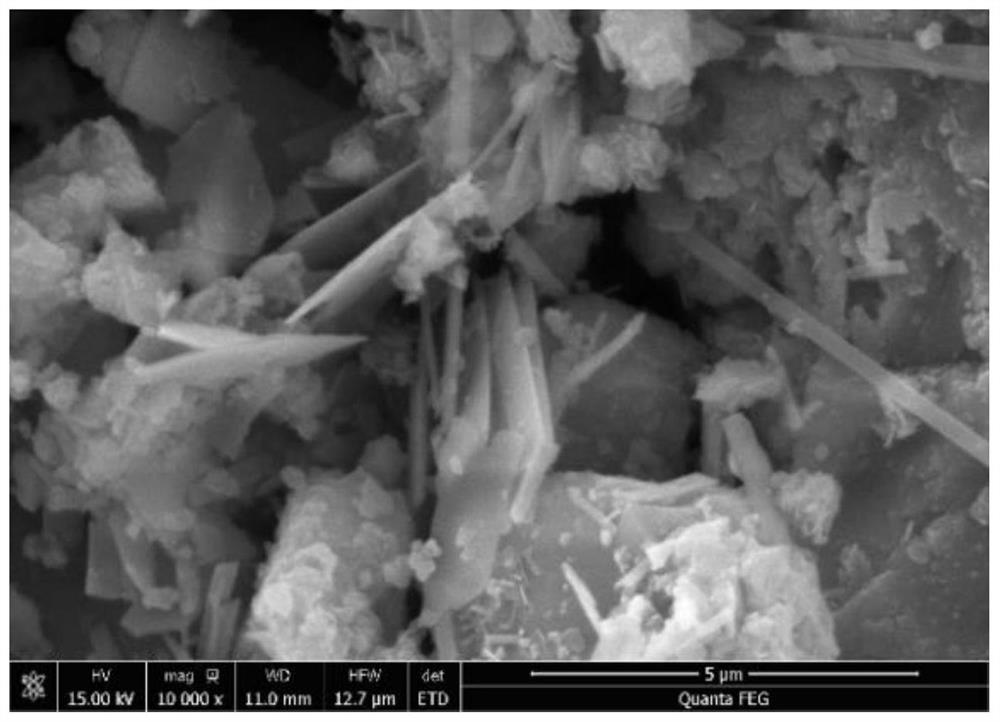

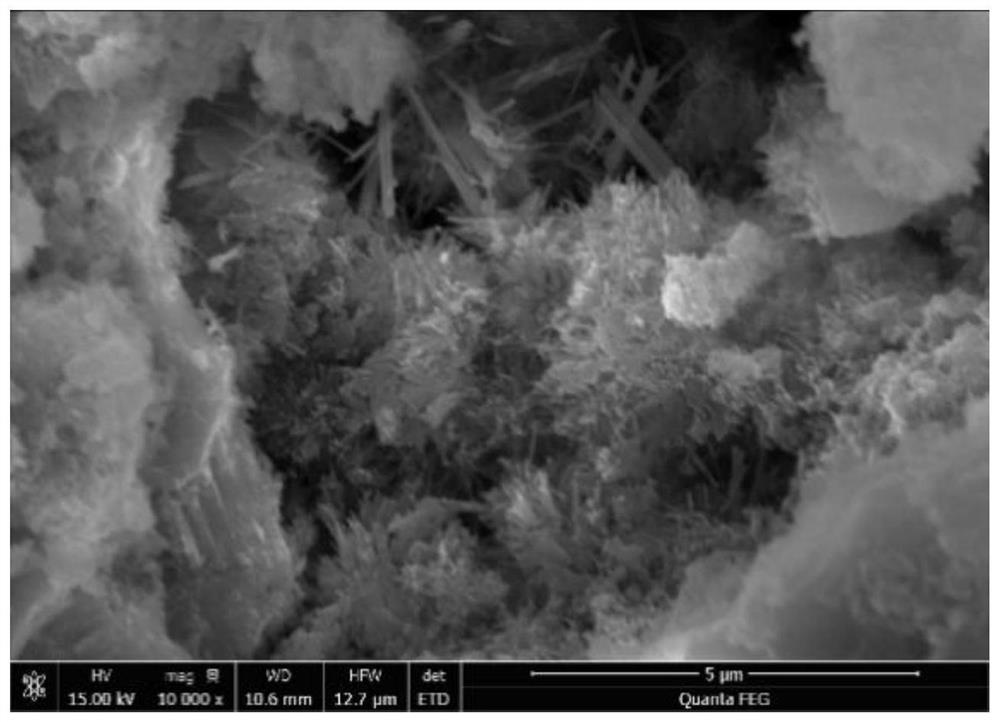

The invention provides a high-adaptability mud-resistant water reducing agent and a preparation method thereof. According to the invention, by metering as 1000 parts in mass, the water reducing agent is mainly prepared from the following materials: 16.8 to 17.3 parts of a phenol alcohol head, 302.1 to 310.7 parts of a cyclic monomer, 0.4 to 1.2 parts of a catalyst, 32.1 to 33.0 parts of an acid substance, 3.2 to 7.9 parts of a reducing agent, 5.6 to 8.6 parts of an initiator, 5.9 to 9.4 parts of a neutralizing agent, 1.2 to 4.8 parts of a chain transfer agent and the balance of deionized water. The polyether monomer is prepared firstly, the acid-ether ratio of the water reducer is designed according to the molecular weight of the prepared polyether, polar functional groups with high adsorbability are introduced into polycarboxylic acid molecules through a free radical polymerization method by utilizing the advantage of high designability of the molecular structure of the polycarboxylic acid, the excellent adsorption and dispersion performance of the water reducing agent is ensured, and the water reducing agent has a very good anti-mud effect.

Owner:WUHAN UNIV OF TECH

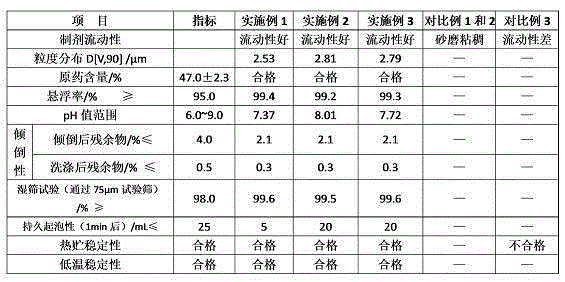

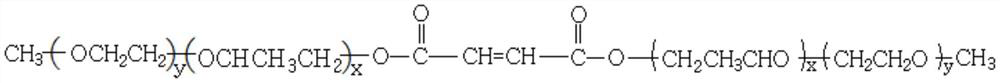

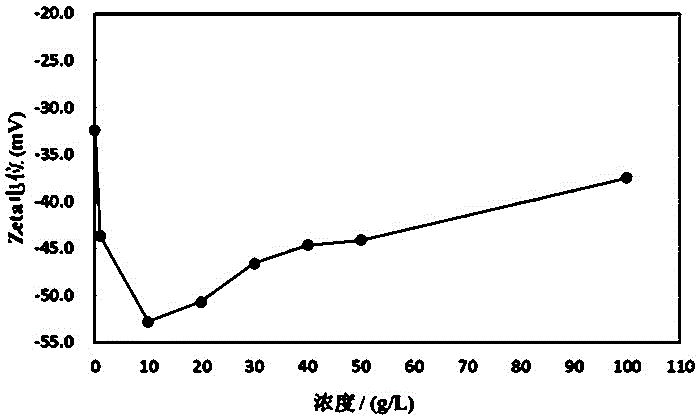

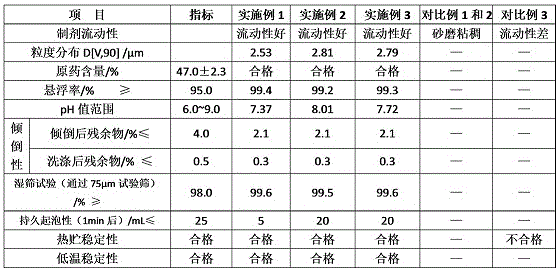

Imidacloprid suspension and preparation method thereof

ActiveCN105028457AImprove adsorption capacityDistributeBiocideAnimal repellantsSuspending AgentsImidacloprid

The invention belongs to the field of pesticides, and concretely relates to a 600g / L imidacloprid suspension and a preparation method thereof. The above preparation comprises, by mass, (47.0+ / -2.3)% of an effective imidacloprid active compound, 3-6% of a synthetic dispersant JM, 2-4% of a wetting agent, 1-8% of a thickener, 0.1-3% of an antifoaming agent, 1-10% of an antifreeze agent, and the balance of water.

Owner:中化化工科学技术研究总院有限公司 +1

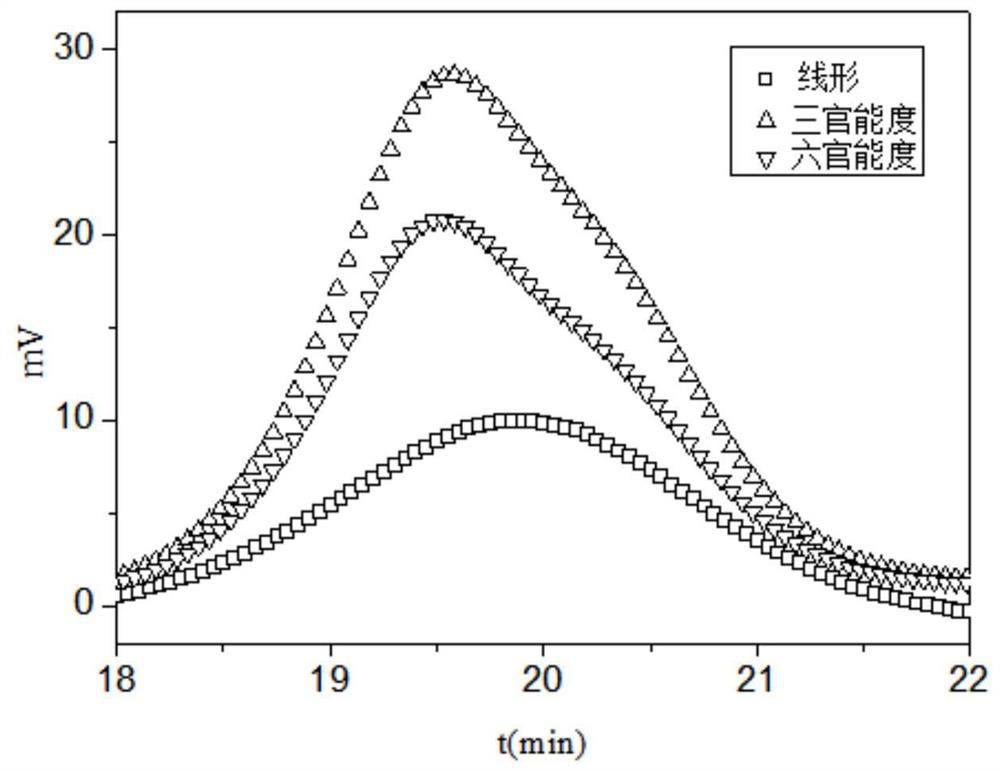

High magnification hard water resistant dispersant, and preparation method and application thereof

PendingCN110358029AGood dispersionImproves performance against 3 times standard hard waterBiocideAnimal repellantsOrganic acidWater dispersible

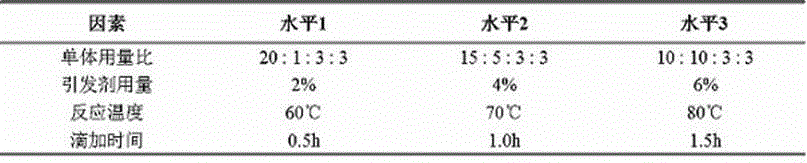

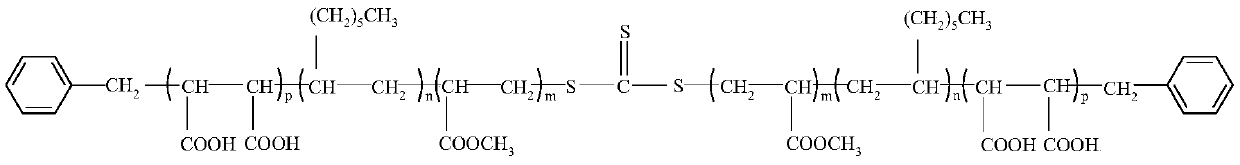

The invention discloses a high magnification hard water resistant dispersant, and a preparation method and application thereof, and belongs to the field of high-molecular compound preparation. An organic acid containing functionalized carboxylic acid and vinyl monomers are copolymerized by taking trisulfide with a symmetrical structure as an RAFT reagent and taking azo or peroxide as an initiatingagent to synthesize an ABA type block copolymer polymer dispersant; the ABA type block copolymer polymer dispersant is applied to triazobenzene water dispersible granules; in a processing process ofthe triazobenzene water dispersible granules, the triazobenzene water dispersible granules have higher dispersibility and persistent stability in high magnification hard water through a steric-hinerance effect and electrostatic repulsion of the high-molecular dispersant.

Owner:YANGZHOU SPED CHEM

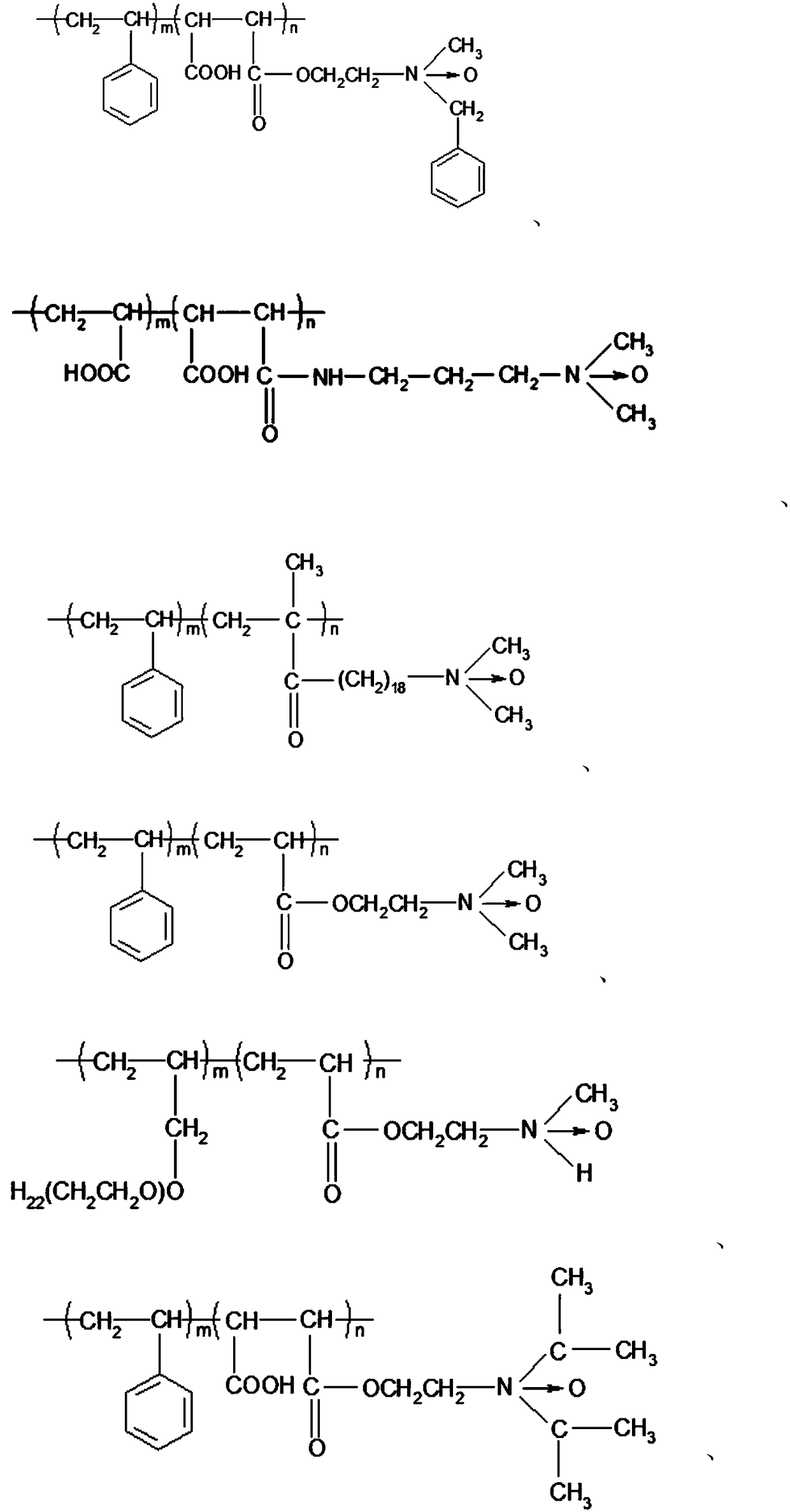

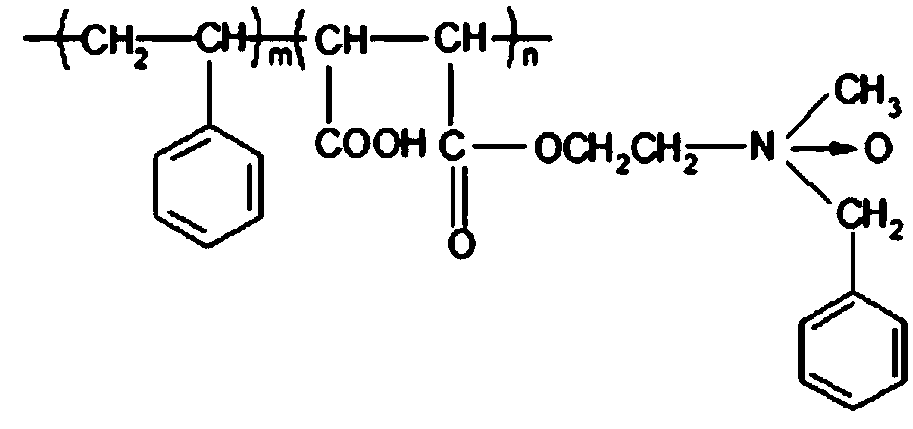

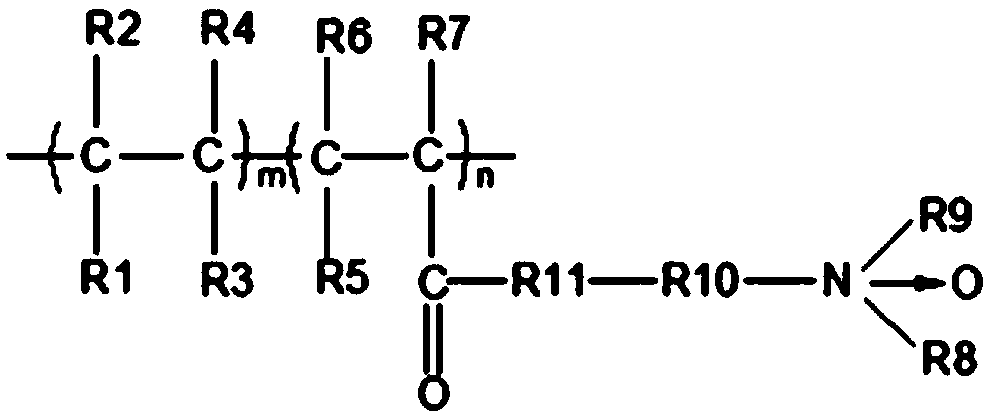

Polymer used as pesticide dispersant and purpose thereof

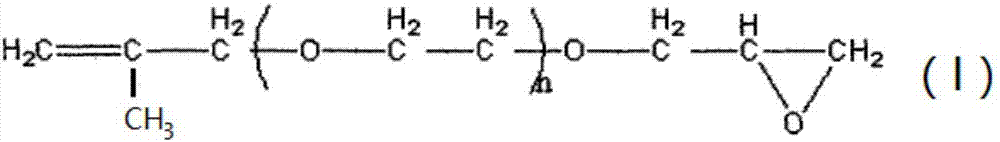

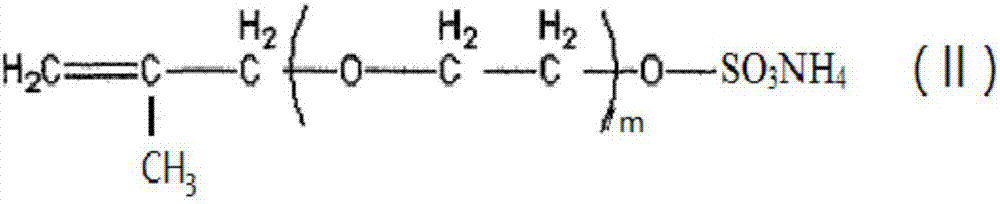

InactiveCN107410300AImprove adsorption capacityGood steric hindranceBiocideFungicidesMethacrylateAlcohol

The invention belongs to the field of polymer synthesis, and particularly relates to a dispersant for pesticide preparations. The dispersant is prepared from (in mass percent) 1% to 30% of glycidyl ether group-terminated methylallyl alcohol polyoxyethylene ether, 1% to 30% of methylallyl alcohol polyoxyethylene ether ammonium sulfate, 5% to 30% of methacrylate, and 10% to 90% of methacrylic acid in a water-soluble initiator under copolymerization, and is used as a pesticide dispersant in pesticide suspension systems, suspension emulsion systems and the like. Due to the uniform distribution of lipophilic and hydrophilic groups in the molecule, and the adsorption and dispersion effect is good, thereby facilitating the smooth preparation of a suspension system with stable performance.

Owner:祥瑞博特生物科技(北京)有限责任公司

Environmentally-friendly biomass flame retardant and processing technology thereof

The invention relates to the technical field of processing and modification of polymer materials, and concretely relates to an environmentally-friendly biomass flame retardant and a processing technology thereof. The technology comprises the following steps: sodium alginate and water are mixed, and stand for swelling, the obtained solution is heated and stirred to achieve dissolving, octenyl succinic anhydride is added, the obtained solution is stirred and reacted at a constant temperature, a sodium hydroxide solution is added to adjust the pH value to 8.1-8.2, and the obtained solution is neutralized with hydrochloric acid after the reaction is finished in order to obtain a modified sodium alginate emulsion; modified rice husks, the modified sodium alginate emulsion, plant essential oil,pretreated bone powder, calcium bicarbonate, n-butyl acetate, Escherichia coli, urea ad N,N-dimethylcyclohexylamine are mixed, and the obtained mixture is stirred at a constant temperature, and then is spray-dried to obtain a blank material; and the blank material is treated with trimethylaluminum-containing nitrogen, then is treated with introduced water-containing nitrogen, and is dried to obtain the environmentally-friendly biomass flame retardant. The environmentally-friendly biomass flame retardant provided by the invention has excellent flame retardant properties and excellent mechanicalproperties.

Owner:王永超

A kind of tetrapolymer dispersant and preparation method thereof

The invention belongs to the field of polymer dispersants, and in particular relates to a tetrapolymer dispersant and a preparation method thereof. The dispersant is made of 30%~60% unsaturated polyether, 10%~40% hydroxyethyl methacrylate, 5%~15% styrene, 5%~15% sodium styrene sulfonate, the above The ratio is mass percentage, the sum of the four is 100%, and the number-average relative molecular weight of the copolymer is 5000-50000; the dispersant can be widely used in the formulation of suspensions such as insecticides, herbicides, and fungicides.

Owner:中化化工科学技术研究总院有限公司 +1

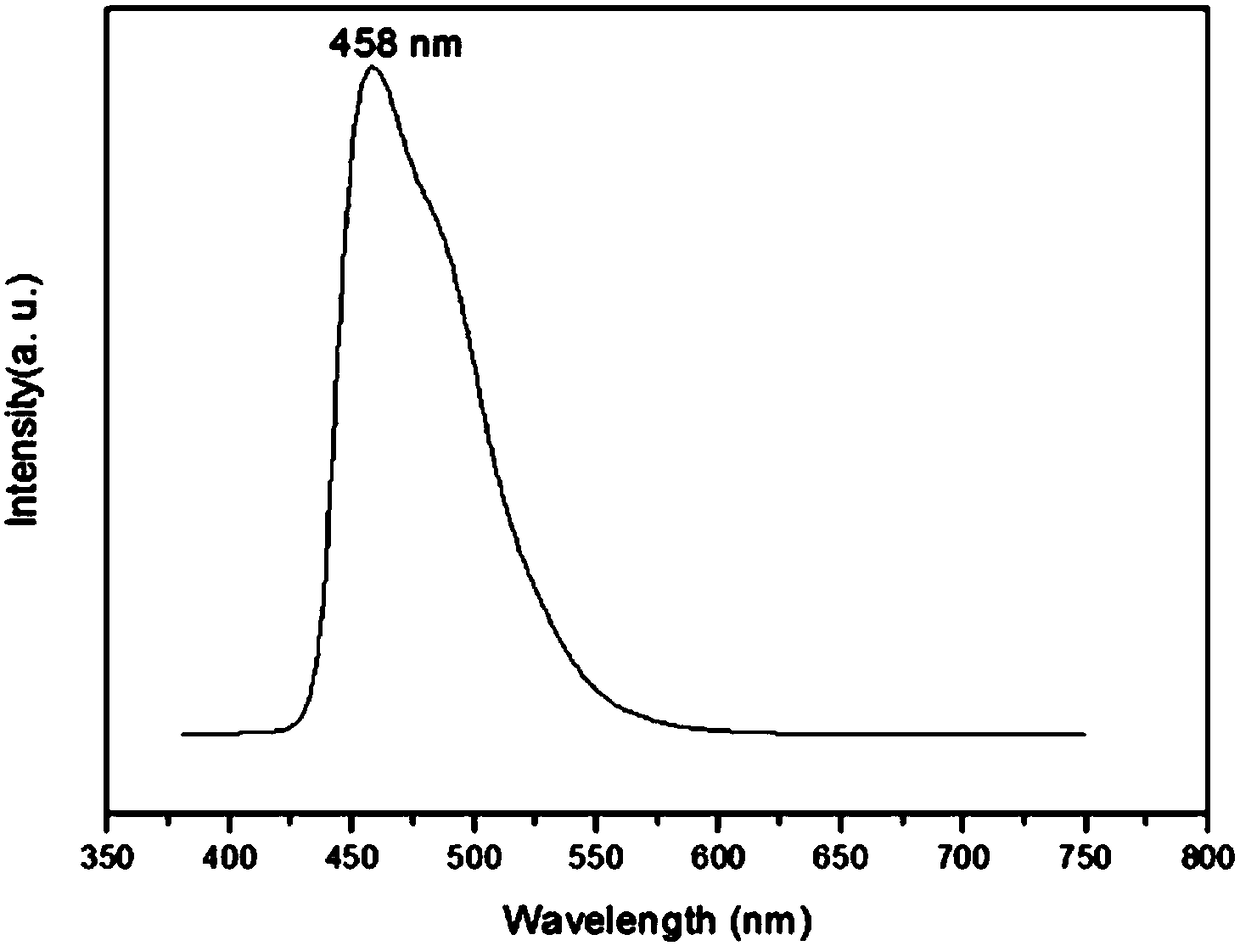

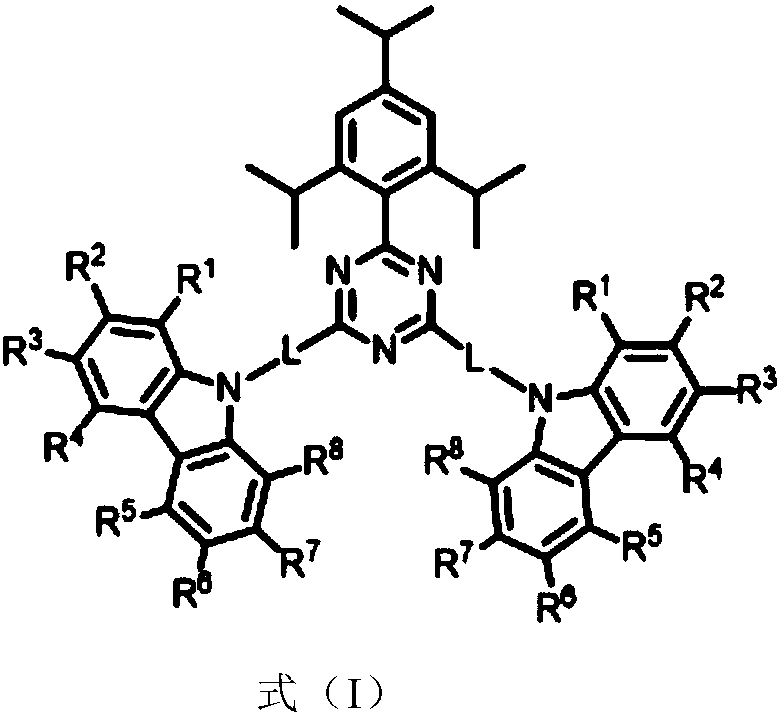

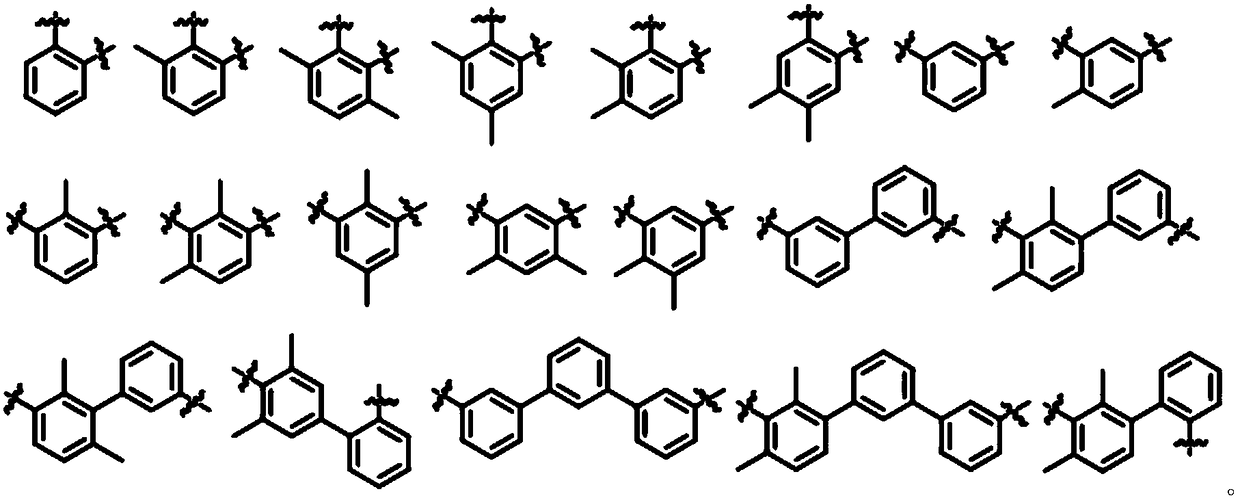

Organic electroluminescent compound and uses thereof, and organic electroluminescent device

PendingCN109111433AReduce accumulationReduce quenchingOrganic chemistrySolid-state devicesCarbazoleTriazine

The present invention discloses an organic electroluminescent compound and uses of the organic electroluminescent compound in preparation of organic electroluminescent devices, and provides an organicelectroluminescent device, which comprise the organic electroluminescent compound. According to the present invention, by introducing the Tip-triazine carbazole structure, the compound achieves the good photoelectric property.

Owner:BEIJING ETERNAL MATERIAL TECH +1

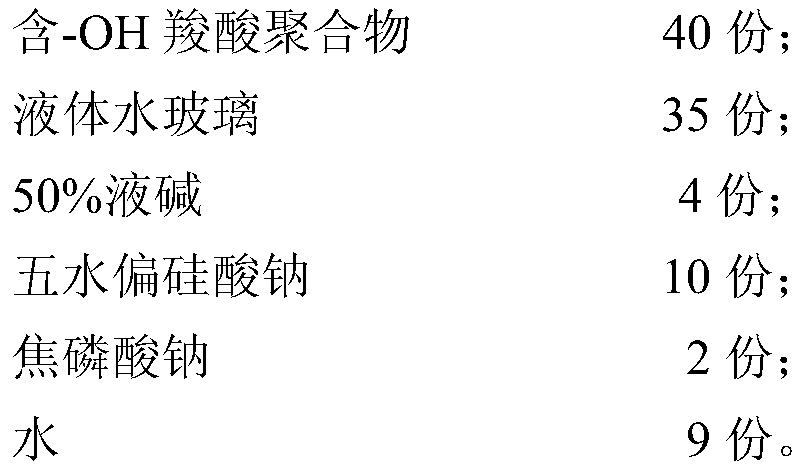

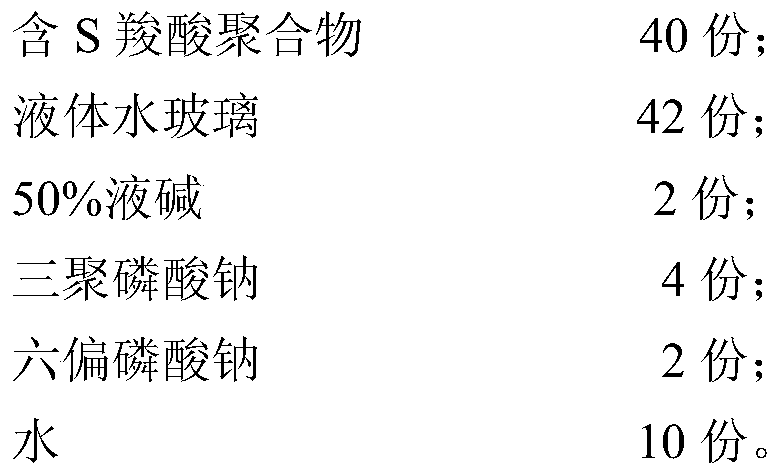

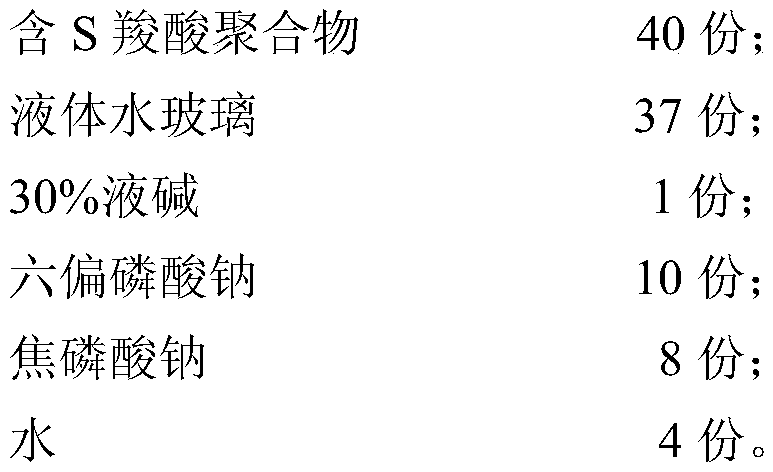

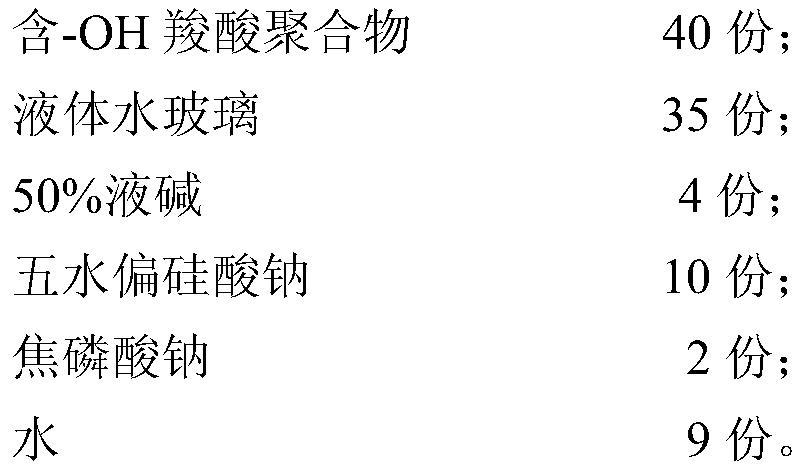

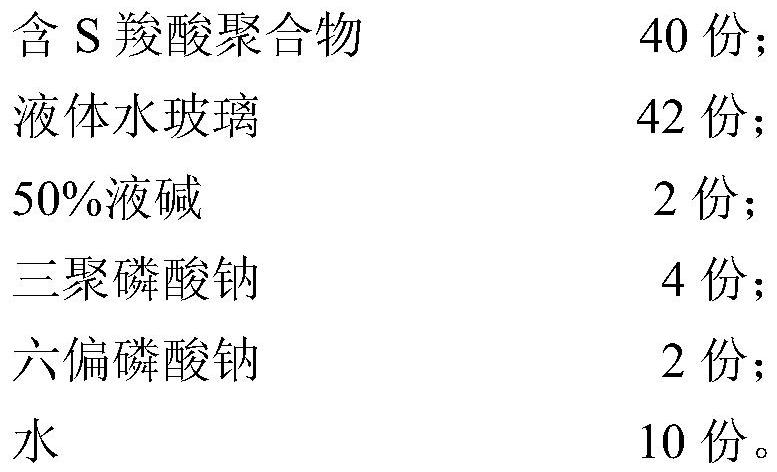

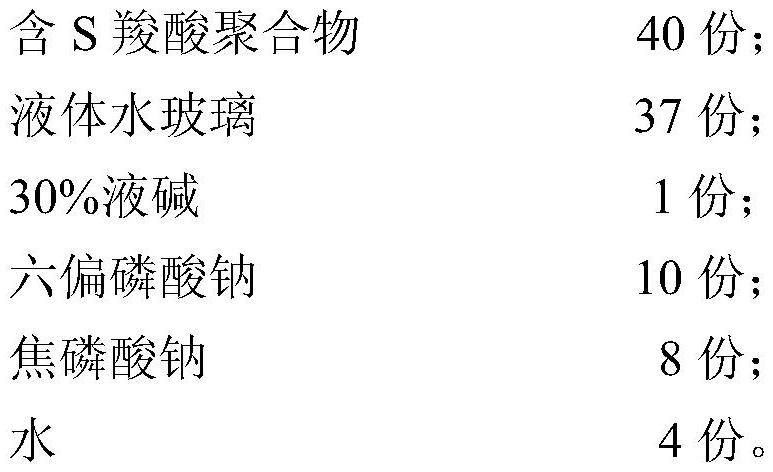

Desulfurization wastewater peptizer as well as preparation method and application thereof

ActiveCN111393143AHas an anchoring effectEvenly dispersedCeramic materials productionClaywaresLiquid waterProcess engineering

The invention discloses a desulfurization wastewater peptizer as well as a preparation method and an application thereof. The desulfurization wastewater peptizer comprises the following components inparts by mass: 30-60 parts of a carboxylic acid polymer, 20-45 parts of liquid water glass, 6-18 parts of a regulator, 1-5 parts of liquid caustic soda and 1-10 parts of water. The desulfurization wastewater peptizer is prepared by the following method: mixing liquid sodium silicate, liquid caustic soda, a part of regulator and water, and uniformly stirring; and then sequentially adding the carboxylic acid polymer and the rest of the regulator in a stirring state, and uniformly mixing to obtain the desulfurization wastewater peptizer. The desulfurization wastewater peptizer disclosed by the invention is wide in raw material source, low in price, green and environment-friendly, and can be used for recycling desulfurization wastewater to prepare slurry with good viscosity and thixotropy. Theinvention overcomes the problem of failure of the conventional peptizer in desulfurization wastewater, can effectively treat desulfurization wastewater, has favorable economic and environmental benefits, and has favorable application prospects.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

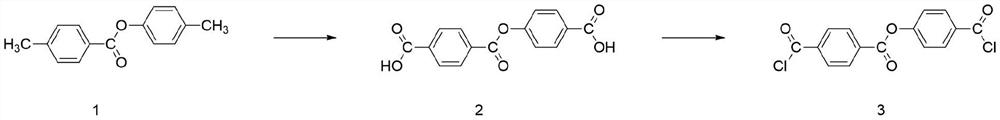

Production process of hydrophobic polyimide film

ActiveCN113549234AHigh structural symmetryHigh electronegativityGroup 4/14 element organic compoundsImidePolymer science

The invention discloses a production process of a hydrophobic polyimide film, which belongs to the technical field of modified polyimide film preparation. The production process of the hydrophobic polyimide film comprises the following steps of preparing a diamine monomer A, reacting a diamine monomer A with a dianhydride monomer to prepare a polyamic acid solution, and performing imidization to obtain a polyimide film. A diamine monomer A is prepared, so that the prepared polyimide has a C-F bond and a siloxane chain with excellent hydrophobic performance, the diamine monomer A is provided with an ester group in the middle, the structural symmetry degree of the diamine monomer A is relatively high, a polymer can locally form microcrystals, and due to the existence of the local microcrystals, the diffusion of water molecules in the polymer is hindered; when water molecules encounter local microcrystals of a macromolecular chain, macromolecular chain segments in a crystalline structure are tightly piled, so that the water molecules cannot permeate and diffuse, the advancing of the water molecules is blocked finally, and the hydrophobic performance of the film is further improved.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

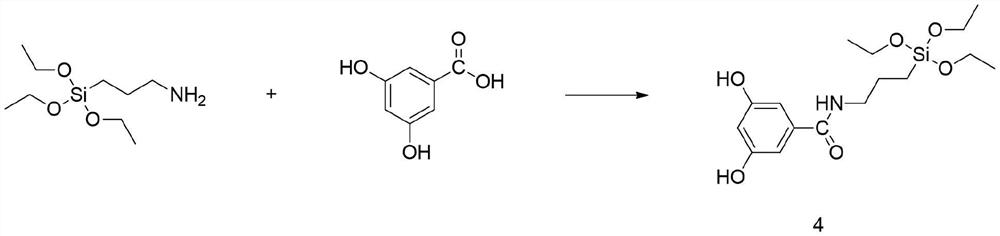

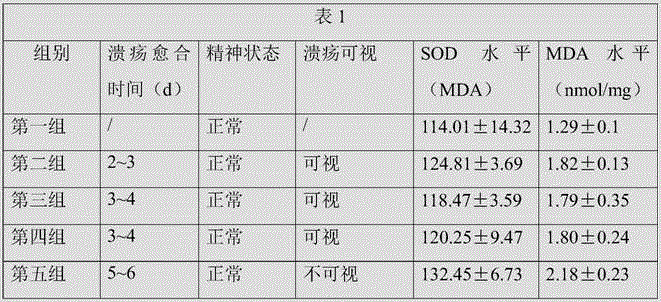

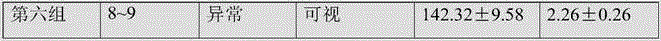

Dental ulcer spray and preparation method thereof

InactiveCN106110293AFormula stablePromote regenerationHydroxy compound active ingredientsDipeptide ingredientsFoaming agentAntioxidant

The invention relates to the field of dental ulcer treatment medicine, in particular to a dental ulcer spray and a preparation method thereof. The dental ulcer spray is prepared from, by mass, 1-3 parts of regeneration promoter, 0.3-0.5 part of anti-inflammatory agent, 1-4 parts of film-forming agent, 0.5-2.5 parts of pore-foaming agent, 0.1-0.2 part of suspending agent, 0.1-0.2 part of antioxidant, 0.1-0.2 part of astringent and 92-98 parts of solvent. The dental ulcer spray is good in treatment effect, and meanwhile has the effects of diminishing inflammation, relieving pain and promoting ulcer healing.

Owner:怡越医疗(广东)有限公司

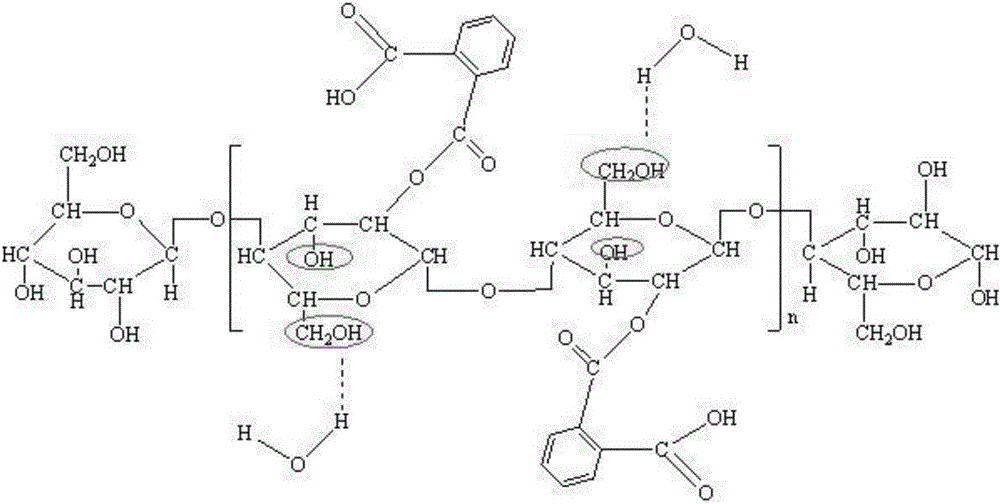

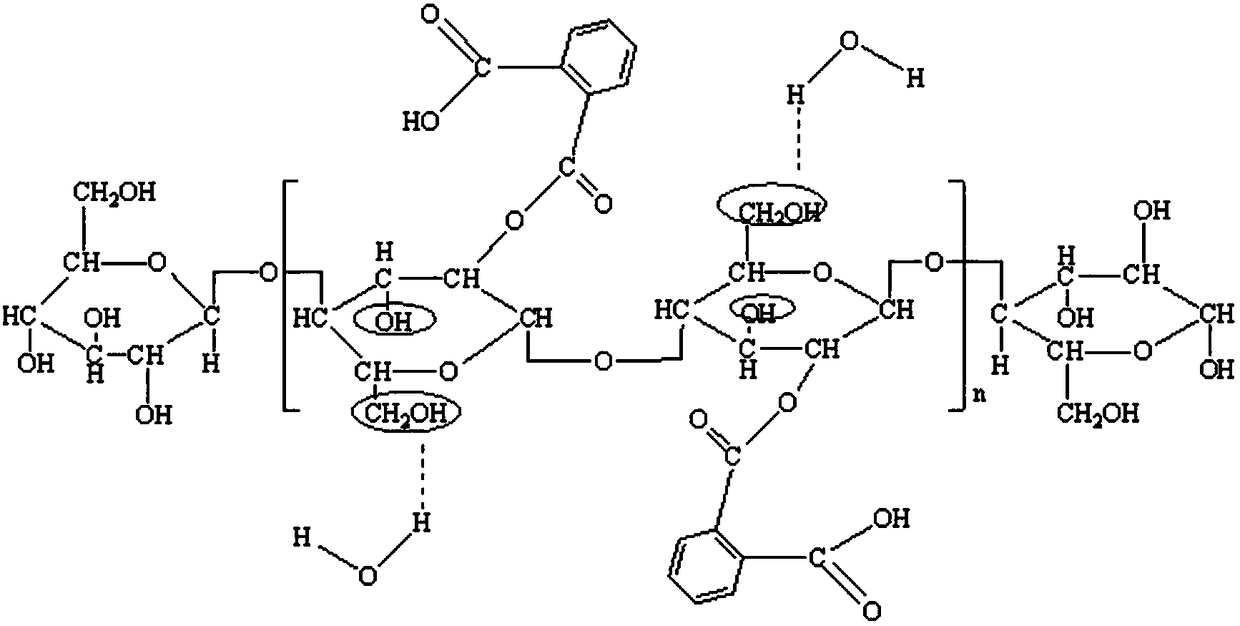

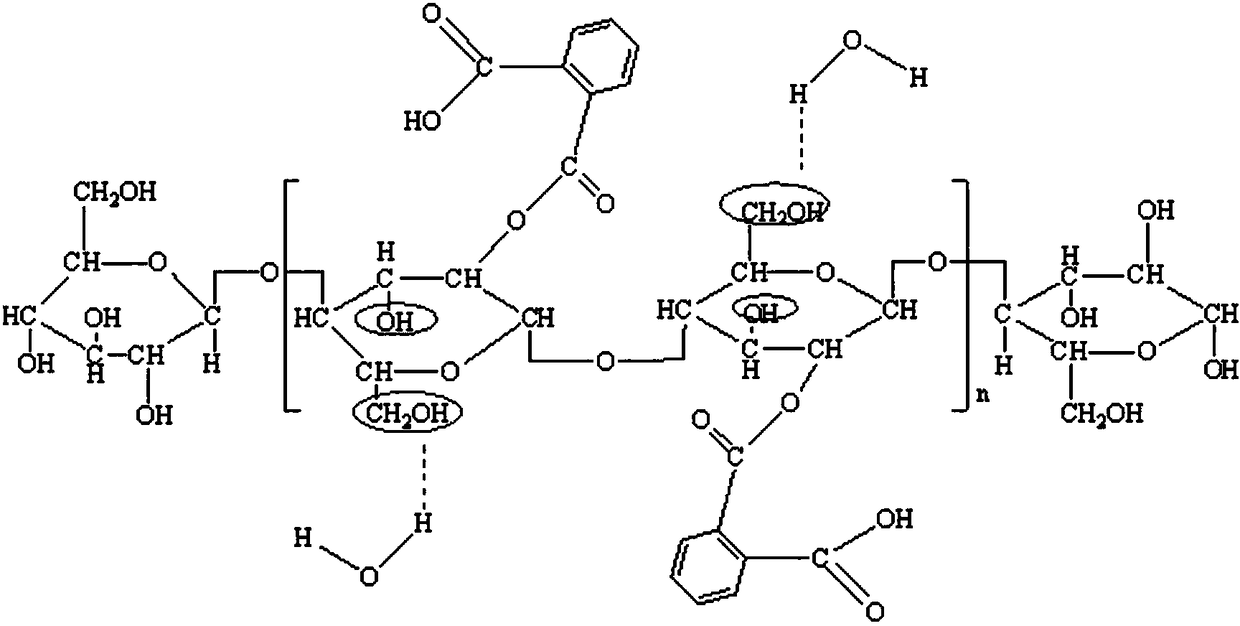

Micro-crystalline cellulose modified polyester preparation method

The invention belongs to the technical field of polyester. In order to solve the hydrophile problem of polyester, the present invention provides a micro-crystalline cellulose modified polyester preparation method. The method comprises in sequential order the steps of preparing the micro-crystalline cellulose and conducting the surface decoration, beating the micro-crystalline cellulose into pulp, and conducting the in-situ addition of the micro-crystalline cellulose. The prepared polyester had a good hydrophile property. Polyhydroxy active site can enable the fiber to be dyed under mild conditions and have an excellent dying property. The polymer can be widely used for preparing fiber with moisture absorbing, sweat dispelling and anti-static properties, and can be used as a close-fitting fabric and a high color fastness fiber product.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

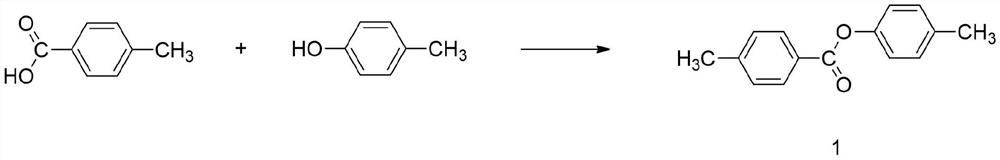

Dispersion agent used for pesticide suspension concentrate and preparation method thereof

InactiveCN109315390AHigh yieldHigh esterification rateBiocideAnimal repellantsSalt resistanceTarget surface

The invention discloses a dispersion agent used for pesticide suspension concentrate. By means of a nitrogenous group in the dispersion agent used for the pesticide suspension concentrate, the salt resistance performance of a preparation is improved, the destructive effect of suspension system salt on the preparation stability is reduced, a carboxyl-containing vinyl monomer co-polymer main structure provides good steric hindrance, electrostatic repulsion and solvation chain effects, and the suspension system physical stability can be guaranteed; in a pesticide application process, the fogdropbouncing performance is inhibited, the deposit rate of a pesticide on a target surface is improved, and the dispersion agent used for the pesticide suspension concentrate is beneficial for improving the utilization efficiency of the pesticide. Meanwhile, the invention discloses a preparation method of the dispersion agent used for the pesticide suspension concentrate; the method is simple, the yield is high, and the product use performance is excellent.

Owner:YANGZHOU SPED CHEM

A kind of desulfurization wastewater degelling agent and its preparation method and application

ActiveCN111393143BHas an anchoring effectEvenly dispersedCeramic materials productionClaywaresLiquid waterProcess engineering

The invention discloses a gelling agent for desulfurization waste water, a preparation method and application thereof. The desulfurization waste degelling agent of the present invention comprises the following components in parts by mass: 30-60 parts of carboxylic acid polymer, 20-45 parts of liquid water glass, 6-18 parts of regulator, 1-5 parts of liquid alkali, 1 to 10 parts of water. The desulfurization waste degelling agent of the present invention is prepared by the following method: mix liquid water glass, liquid caustic soda, part of the regulator and water, and stir evenly; Evenly, the desulfurization waste water hydrolysis agent is prepared. The desulfurization waste water gelling agent of the invention has wide sources of raw materials, low price and environmental protection, and can be used to recycle desulfurization waste water to prepare mud with good viscosity and thixotropy. The invention overcomes the failure problem of conventional debonding agents in desulfurization wastewater, can effectively treat desulfurization wastewater, has good economic and environmental benefits, and has good application prospects.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

Star cationic graphene dispersant and its application

ActiveCN110655596BStrong entropy protectionGood steric hindranceCarbon compoundsPolymer scienceAcrylate ester

Owner:中润超油(北京)新材料有限公司

Stable pumping type slump retaining agent and preparation method thereof

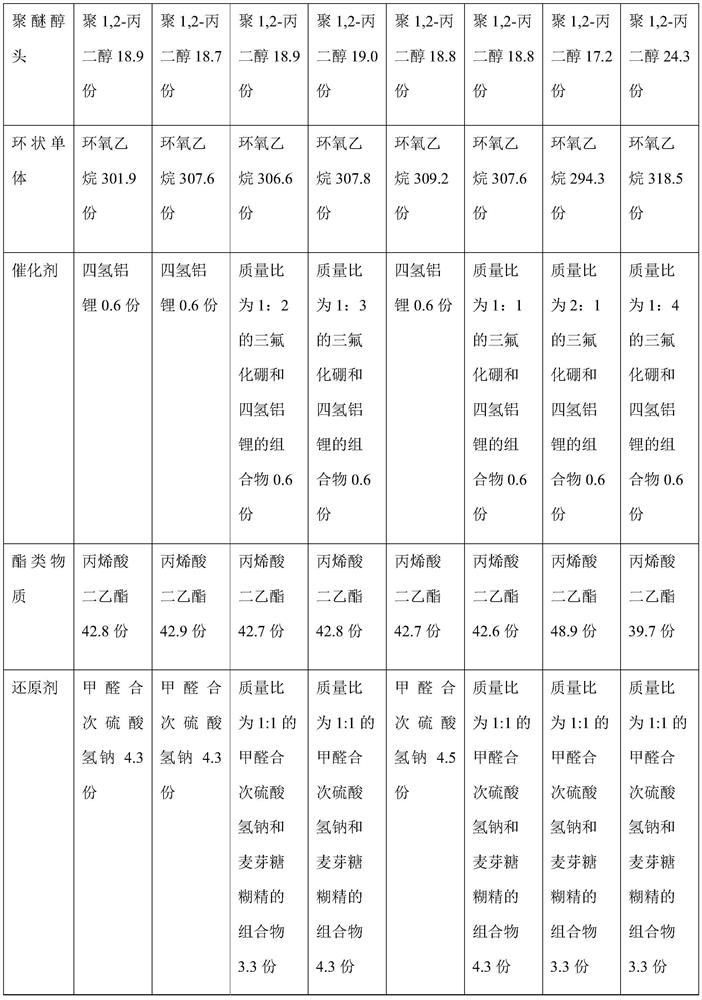

The invention discloses a stable pumping type slump retaining agent and a preparation method thereof, and belongs to the technical field of concrete. The slump retaining agent is mainly prepared by polymerizing the following components in parts by mass: 18.6 to 20.1 parts of polyether alcohol, 301.8 to 310.0 parts of cyclic monomer, 0.3 to 0.9 part of catalyst, 42.5 to 43.6 parts of ester substance, 2.1 to 5.4 parts of reducing agent, 2.5 to 4.4 parts of initiator, 0.8 to 2.6 parts of chain transfer agent, 5.3 to 7.9 parts of neutralizing agent and the balance of water, wherein the total mass of the raw materials is 1000 parts. The polyether monomer is firstly prepared, the acid-ether ratio of the prepared slump retaining agent is determined according to the molecular weight of the prepared polyether, and the coating performance of the molecules of the slump retaining agent is improved. The molecular branch chain of the slump retaining agent is a polyether branch chain which has good flexibility and hydrophilicity and shows the coating performance and high slump retaining performance of the slump retaining agent.

Owner:HUBEI UNIV OF TECH

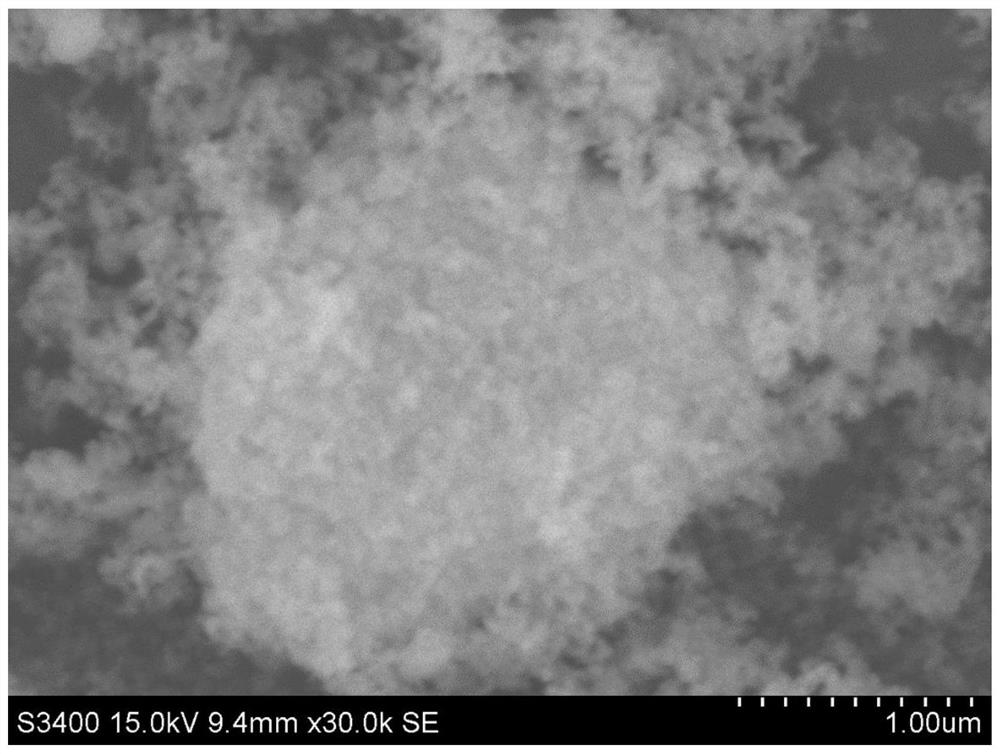

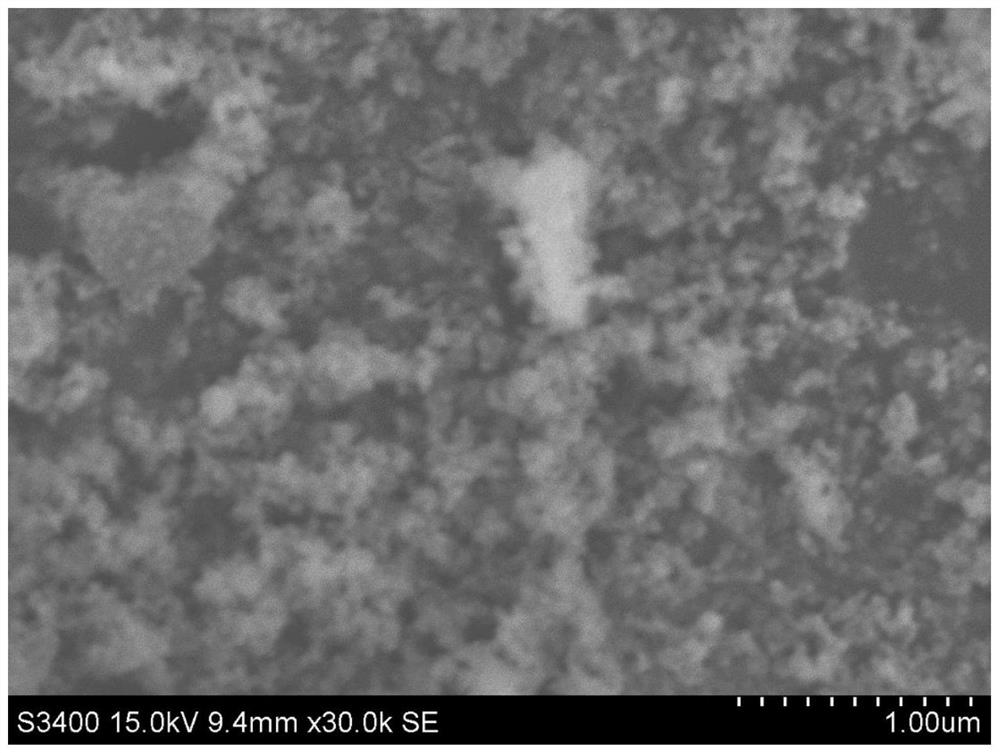

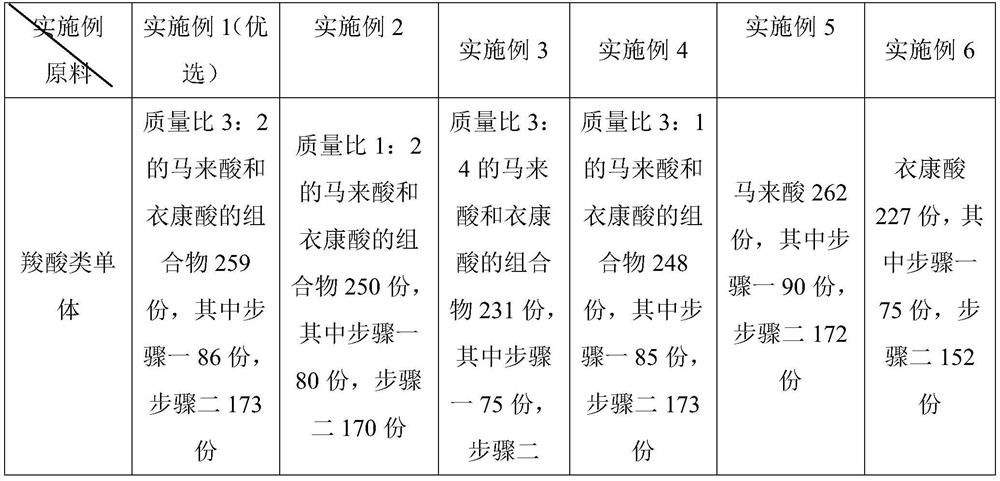

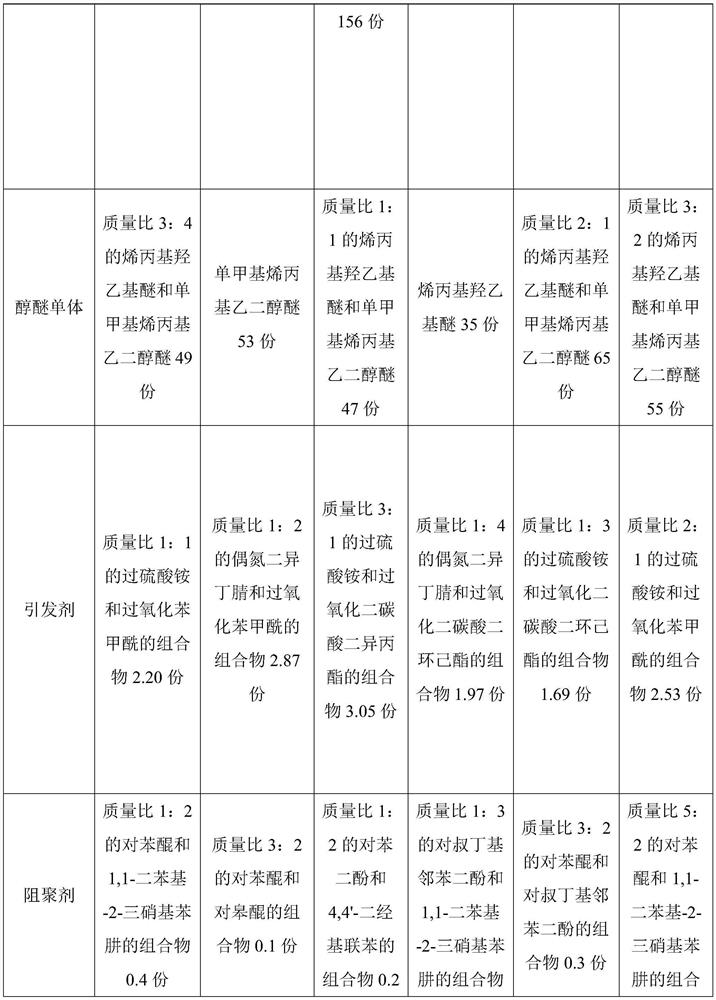

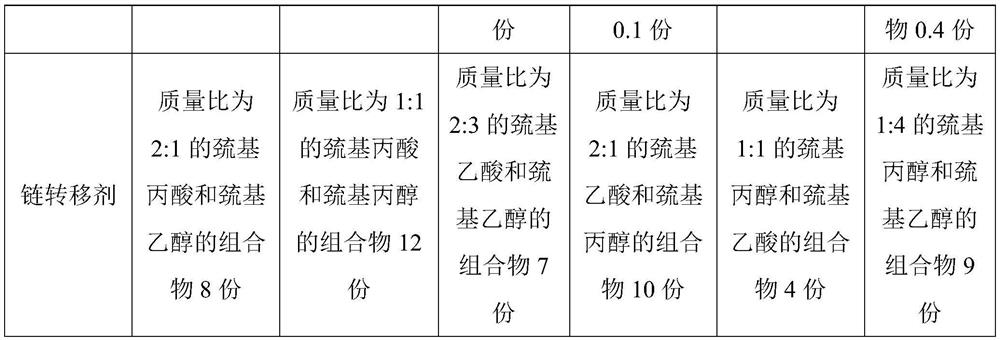

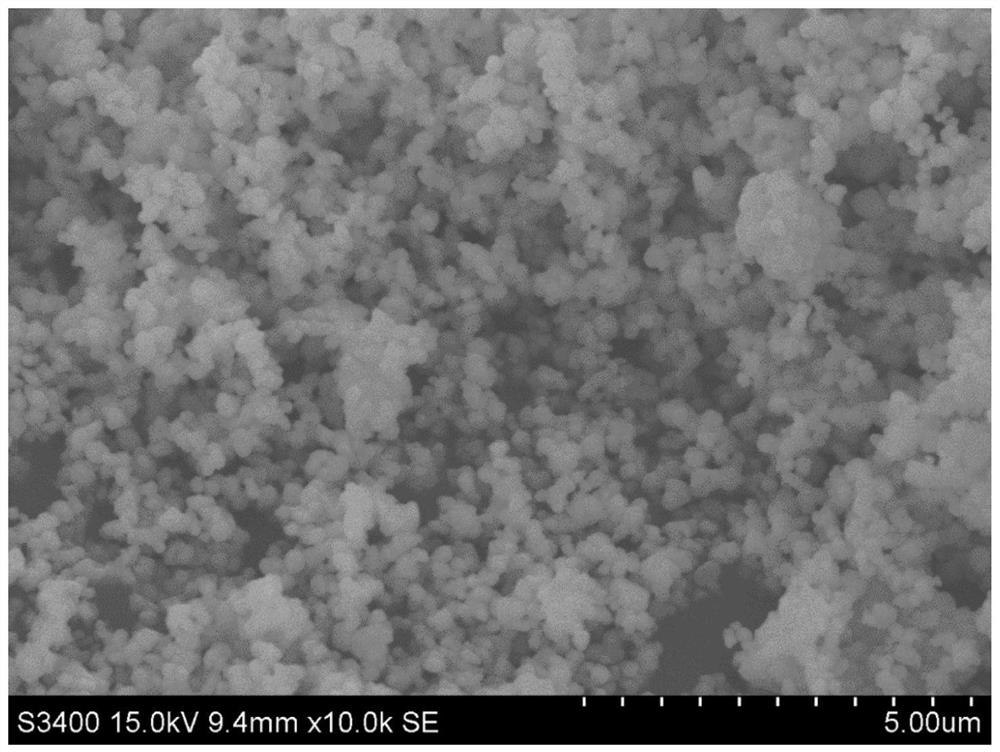

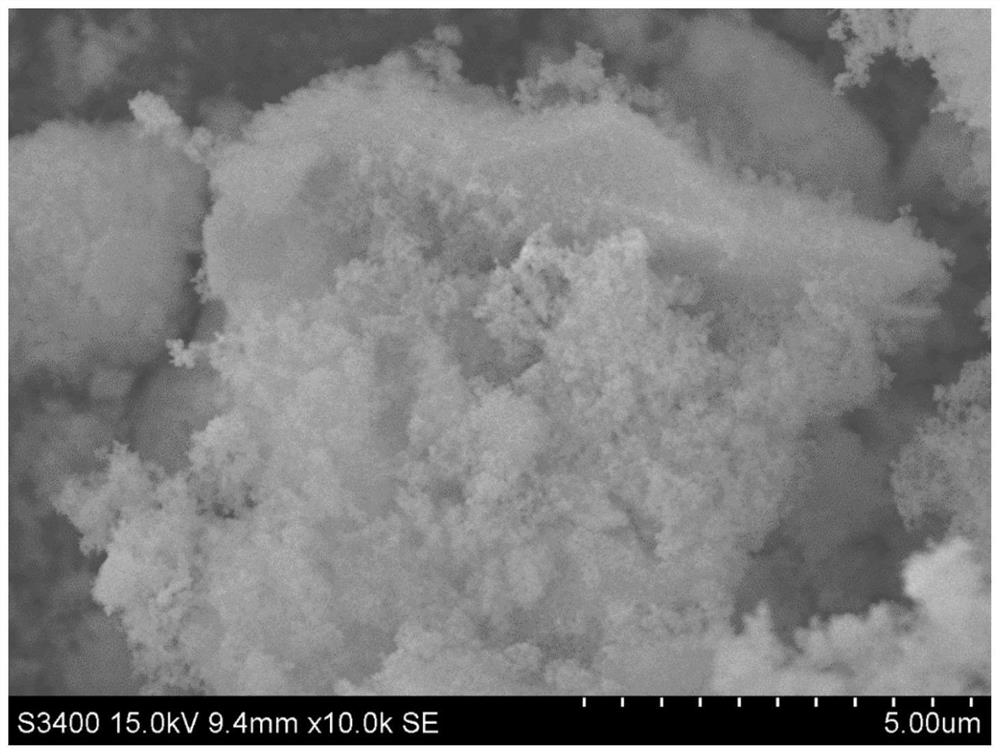

Preparation method of nano zirconium oxide powder dispersing agent and nano zirconium oxide powder dispersing agent

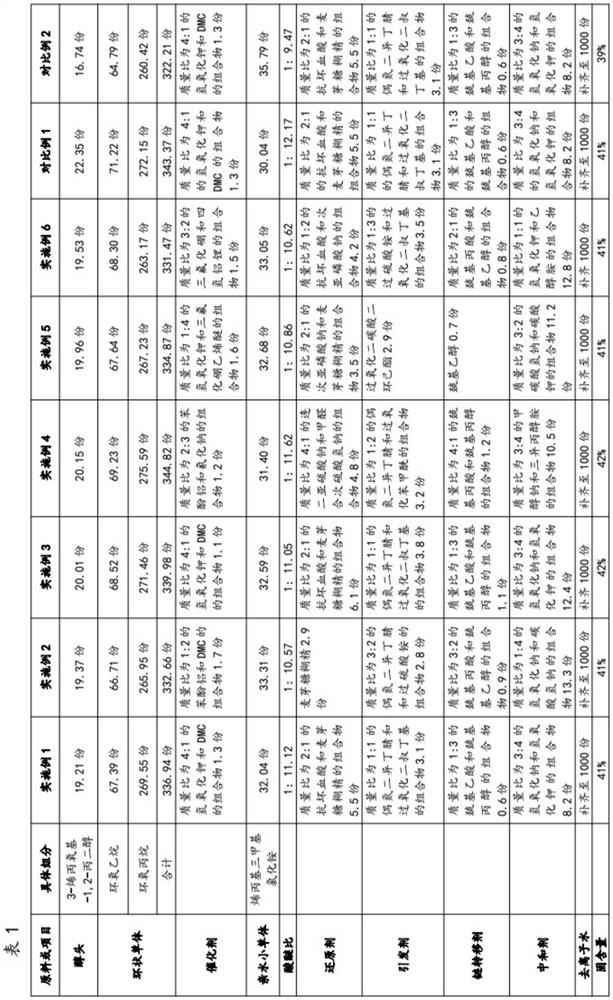

ActiveCN112920340AGood steric hindranceImprove adsorption capacityPigment treatment with macromolecular organic compoundsPtru catalystAlcohol

The invention provides a preparation method of a nano zirconium oxide powder dispersing agent and the nano zirconium oxide powder dispersing agent prepared by the method. The preparation method of the nano zirconium oxide powder dispersing agent comprises the following steps: synthesizing polyether from an alcohol head and a cyclic monomer under the action of a catalyst; reacting the polyether with a hydrophilic small monomer under the action of a reducing agent, an initiator and a chain transfer agent to prepare a polyether dispersant; and adding a neutralizing agent into the polyether dispersing agent to prepare the nano zirconium oxide powder dispersing agent. The total amount of the raw materials is 1000 parts by mass, the dosage of each raw material is as follows: 19.17-20.18 parts by mass of an alcohol head, 329.45-346.79 parts by mass of a cyclic monomer, 1.1-1.7 parts by mass of a catalyst, 31.38-33.43 parts by mass of a hydrophilic small monomer, 2.5-6.1 parts by mass of a reducing agent, 2.4-3.9 parts by mass of an initiator, 0.6-1.2 parts by mass of a chain transfer agent, 7.9-13.4 parts by mass of a neutralizing agent and the balance of water, the alcohol head is 3-allyloxy-1, 2-propylene glycol, the cyclic monomer is ethylene oxide and propylene oxide, and the hydrophilic small monomer is allyl trimethyl ammonium chloride.

Owner:HUBEI UNIV OF TECH

A kind of microcrystalline cellulose modified polyester fiber and preparation method thereof

ActiveCN106521690BGood steric hindranceAvoid hydrolysisElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to the technical field of polyester, which solves the problem of poor hydrophilic performance of polyester fiber. The invention provides a method for preparing microcrystalline cellulose-modified polyester fiber. The method comprises the following steps: cellulose crystallite preparation and its surface modification, cellulose crystallite beating, cellulose crystallite in-situ addition, and melt spinning on microcrystalline cellulose-modified polyester. The prepared microcrystalline cellulose-modified polyester fiber has good moisture absorption performance, polyhydroxy active site active sites are provided in the fiber, fiber is capable of dyeing under mild condition, has good dyeing performance, can be widely sued for preparing moisture absorbable and breathable antistatic fiber, and can be taken as fabrics which is suitable for skin.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

Preparation method of high-strength paper-based friction composite material

InactiveCN111057307APrevent flocculation and agglomerationGood compatibilityCellulosePolyvinyl alcohol

The invention relates to a preparation method of a high-strength paper-based friction composite material, which belongs to the technical field of friction materials. According to the invention, polypropylene fiber, bamboo fiber and aramid fiber are used as raw materials; carboxymethyl cellulose, polyvinyl alcohol and methyl triethyl silane are added; the high-strength paper-based friction composite material is prepared; the nano aluminum oxide, the silicon carbide microspheres and the talcum powder are added; the added nano aluminum oxide can be used as a hard point grinding material of the paper-based friction material; the friction factor and the wear resistance of the friction material can be effectively improved; the silicon carbide microspheres are added, the holes can enable the adhesive to be better bonded with the resin; the bonding strength of the paper-based friction material is improved, oil flowing can be promoted due to the holes, the friction material is more heat-resistant, the friction factor and the energy absorption rate of the friction material can be improved, the friction performance of the material can be adjusted by adding talcum powder, and the friction material has better comprehensive performance.

Owner:李可禛

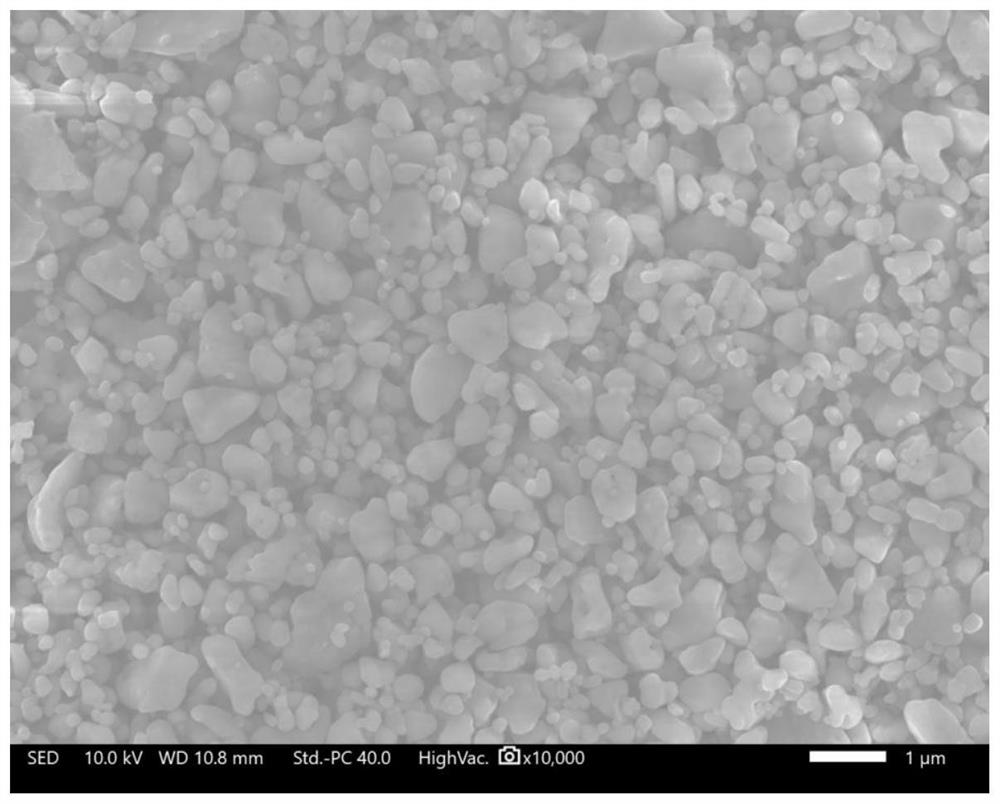

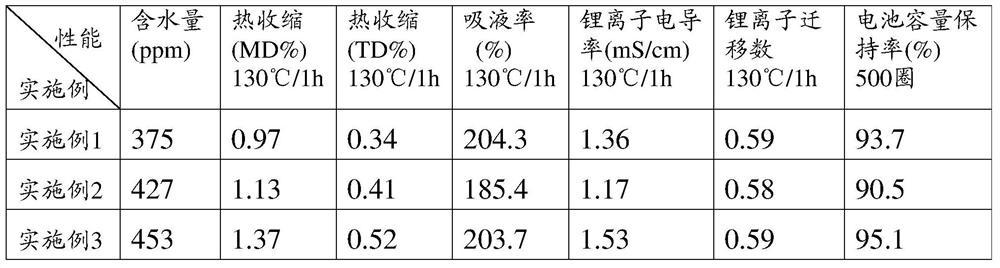

Ceramic coating diaphragm slurry, ceramic composite diaphragm, preparation method and application thereof

ActiveCN109088031BImprove stabilitySimple preparation stepsSecondary cellsCell component detailsCeramic compositeCeramic coating

Owner:湖南烁普新材料有限公司

A kind of preparation method and application of inorganic pigment and filler aqueous dispersant

ActiveCN112940194BGood steric hindranceAdjust applicabilityCoatingsPigment pastesPolymer scienceInorganic pigments

A preparation method and application of an inorganic pigment and filler aqueous dispersant, including: providing a first monomer and a second monomer, the first monomer includes an ethylenically unsaturated monomer having a carboxyl group, and the second mono The body includes an ethylenically unsaturated monomer containing an amide group; providing an unsaturated block polyether, providing an initiator of a redox system; mixing the first monomer, the second monomer, The unsaturated block polyether, and the redox system initiator, make the first monomer, the second monomer and the unsaturated block polyether undergo a copolymerization reaction, and use a neutralizing agent Adjust the pH to 6-8 to obtain the aqueous dispersion of inorganic pigments and fillers. The dispersant of the present invention has a good dispersing and viscosity-reducing effect on inorganic pigments and fillers, high grinding efficiency, strong wetting and dispersing effect on the surface of pigments, good tinting strength, and strong storage stability, ensuring that inorganic pigments and fillers are Good application in color paste and coating system.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

A kind of imidacloprid suspending agent and preparation method thereof

ActiveCN105028457BImprove adsorption capacityDistributeBiocideAnimal repellantsImidaclopridAntifoam agent

Owner:中化化工科学技术研究总院有限公司 +1

Machine-made sand regulator of alcohol ether modified carboxylic acid polymer and preparation method of machine-made sand regulator

The invention provides a machine-made sand regulator of an alcohol ether modified carboxylic acid polymer and a preparation method of the machine-made sand regulator. The preparation method comprises the following steps: firstly, adding 75-91 parts of carboxylic acid monomer acid, 33-67 parts of alcohol ether monomer, 2-4 parts of chain transfer agent, 0.1-0.3 part of polymerization inhibitor and water into a reaction kettle provided with a stirrer; conducting heating to 80-90 DEG C by adopting a water bath; then using 150-175 parts of carboxylic acid monomers, 0.1-0.3 part of a polymerization inhibitor and 178-187 parts of water to prepare a solution A, using 1.64-3.21 parts of an initiator, 2-8 parts of a chain transfer agent and water to prepare a solution B, and dropwise adding the solution A and the solution B into the reaction kettle through a dropwise adding pump, wherein the solution A is dropwise added for 1-1.5 hours, and the solution B is dropwise added for 1-2 hours; and after dropwise adding the solution A and the solution B, preserving heat for 1-2 hours, conducting cooling, conducting discharging, and replenishing water to 1000 parts, thereby obtaining the machine-made sand regulator. By introducing the alcohol ether monomer, the side chain length and flexibility of a polymer molecular chain are increased, the dispersing performance of the polymer is improved, the polymer can adapt to machine-made sand of different grades, and the use performance of the machine-made sand is improved.

Owner:HUBEI UNIV OF TECH

A kind of prefabricated component early-strength concrete water reducer and preparation method thereof

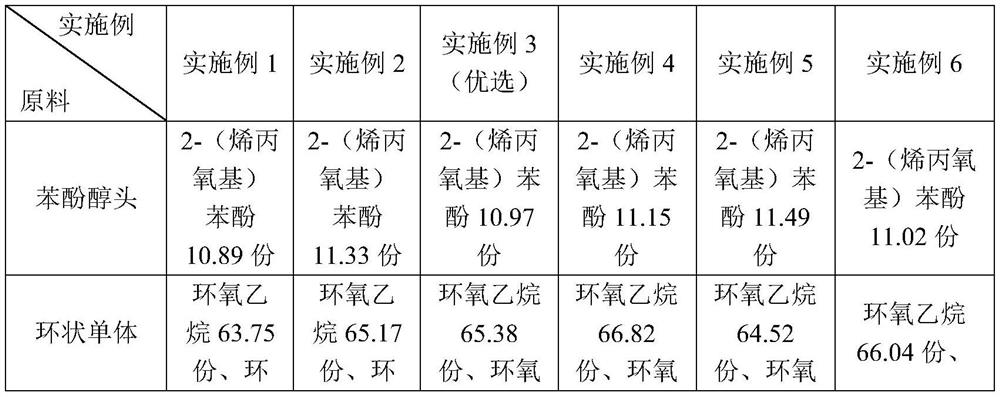

The invention provides an early-strength concrete water reducer for prefabricated components and a preparation method thereof. Based on 1000 parts by mass, the raw materials of the water reducer are as follows: 10.88-11.49 parts of phenol alcohol head, 313.96-331.40 parts of cyclic monomer, 0.4-1.2 parts of catalyst, 35.09-37.04 parts of acid substances, 3.4-7.9 parts of Reducing agent, 5.7-8.6 parts of initiator, 6.1-9.4 parts of neutralizing agent, 1.2-4.7 parts of chain transfer agent, and the rest are deionized water. In the present invention, polyether monomers are firstly prepared, and the acid-ether ratio for preparing the water-reducer is determined according to the molecular weight of the prepared polyether, so as to improve the coating performance of the water-reducer molecules. Moreover, the molecular branch of the water reducing agent is a polyether branch, which has good flexibility and can play a good role in steric hindrance.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of microcrystalline cellulose modified polyester

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

A kind of machine-made sand conditioner of alcohol ether-modified carboxylic acid polymer and preparation method thereof

Owner:HUBEI UNIV OF TECH

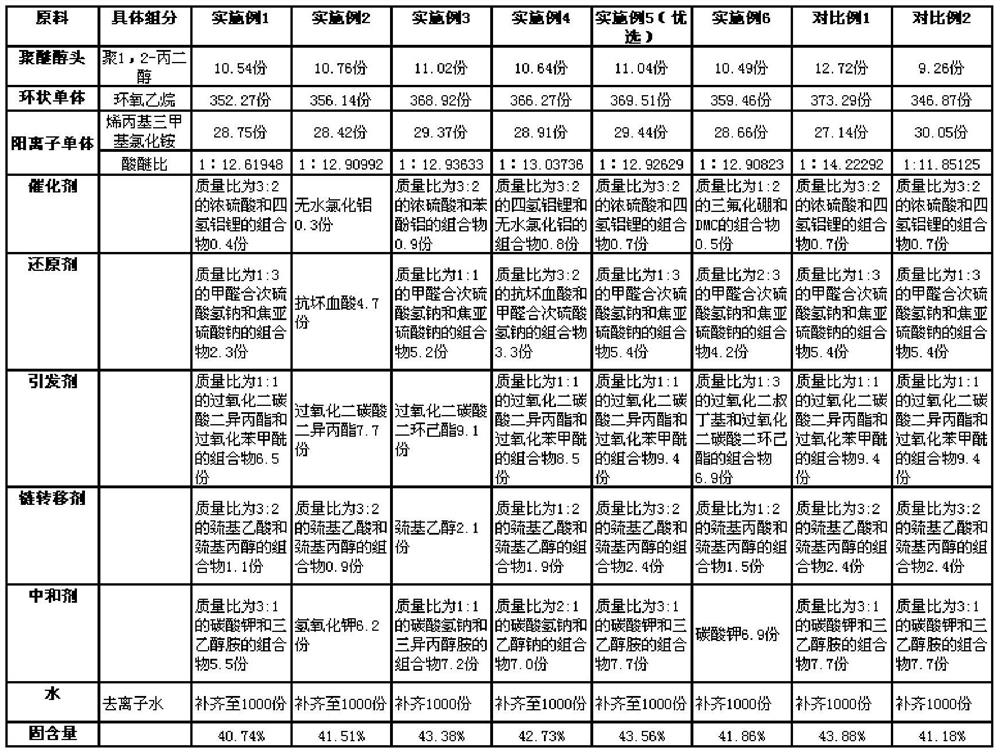

A kind of preparation method of stable cationic pigment dispersant and stable cationic pigment dispersant

The invention provides a preparation method of a stable cationic pigment dispersant and a stable cationic pigment dispersant. The pigment dispersant is mainly prepared from the following materials: 10.49-11.04 parts of polyether alcohol, 351.49-369.51 parts Cyclic monomer, 0.3-0.9 part of catalyst, 28.02-29.45 part of cationic monomer, 2.1-5.4 part of reducing agent, 6.2-9.5 part of initiator, 5.3-7.9 part of neutralizing agent, 0.8-2.6 part of chain transfer agent, and the rest for deionized water. In the present invention, polyether monomers are firstly prepared, and the acid-ether ratio of the dispersant is determined according to the molecular weight of the prepared polyether, so as to improve the coating performance of the dispersant molecules. And the molecular branch of the dispersant is a polyether branch, which has good flexibility and can play a good role in steric hindrance.

Owner:HUBEI UNIV OF TECH

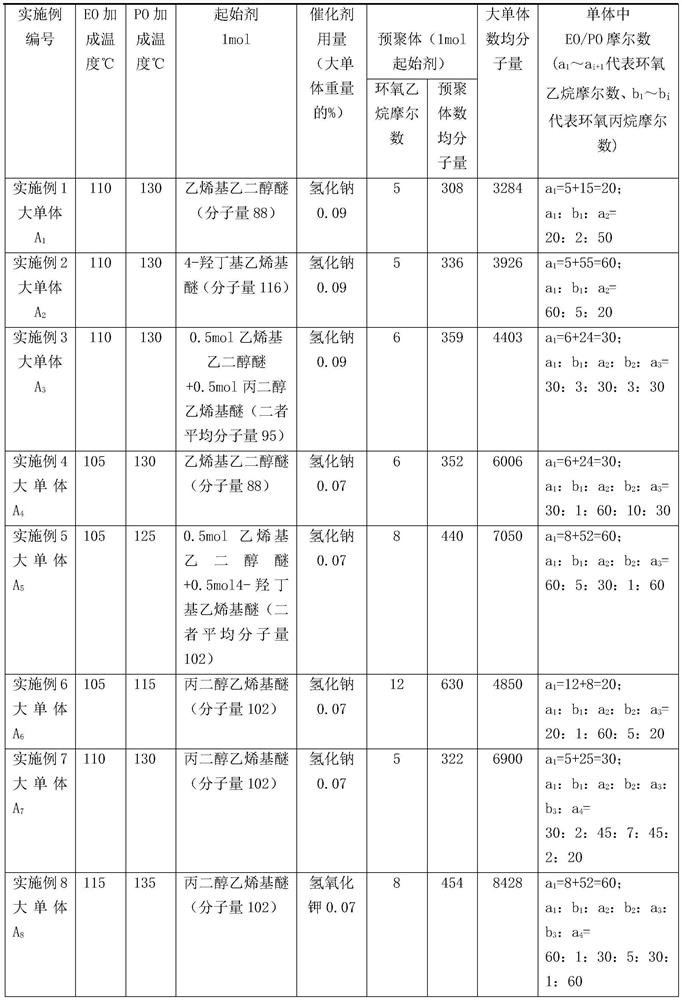

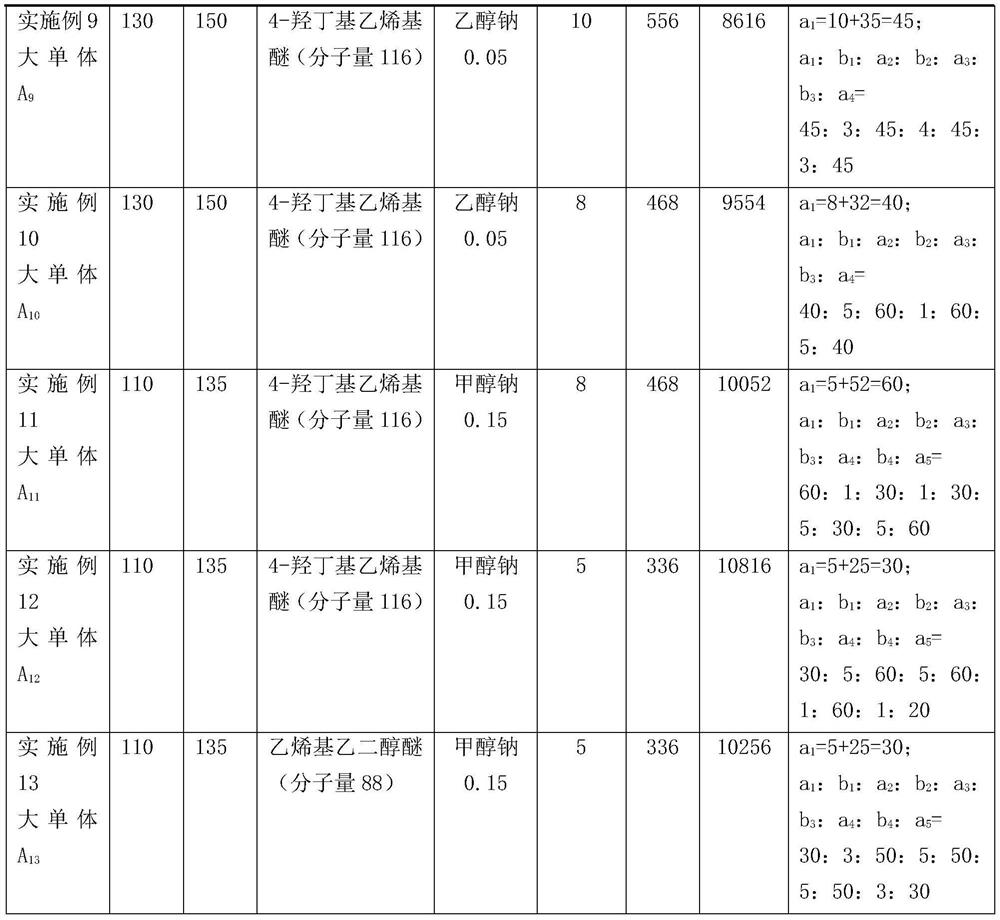

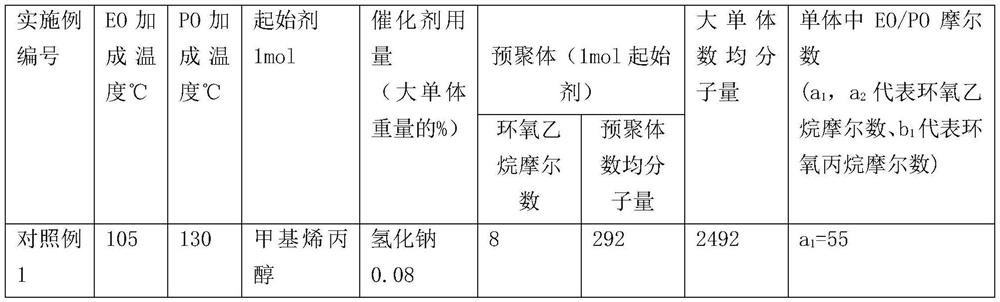

A kind of macromonomer and the method for preparing polycarboxylate water reducer with it

The invention discloses a macromonomer and a method for preparing a polycarboxylate water-reducer by using it. The preparation of the macromonomer includes adding an initiator or its polyoxyethylene ether prepolymer, adding a catalyst, and alternately adding epoxy Ethane and propylene oxide undergo ring-opening polymerization; the ring-opening polymerization temperature of ethylene oxide is 100-130°C; the ring-opening polymerization temperature of propylene oxide is 115-150°C, and the polyoxygen containing the starting unit Polymerized macromonomer with alternating segments of vinyl ether and polyoxypropylene ether; the number of moles of a single segment of polyoxyethylene ether is 20 to 60, the number of moles of a single segment of polyoxypropylene ether is 1 to 10, polycarboxylic acid Preparation of water reducer: Carry out free radical copolymerization reaction with redox system, drop monomer b and auxiliary agent into macromonomer and tank bottom water, trigger free radical polymerization reaction to obtain polycarboxylate water reducer, this product The water reducing rate can reach 25%-50%, the mixing amount is low, the cost of concrete is low, and the effect of slump retention is better.

Owner:北京砼帮汇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com