Ceramic coating diaphragm slurry, ceramic composite diaphragm, preparation method and application thereof

A technology of ceramic slurry and ceramic coating, which is applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve problems such as decomposition and battery performance degradation, and achieve improved safety, improved pressure and temperature resistance, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

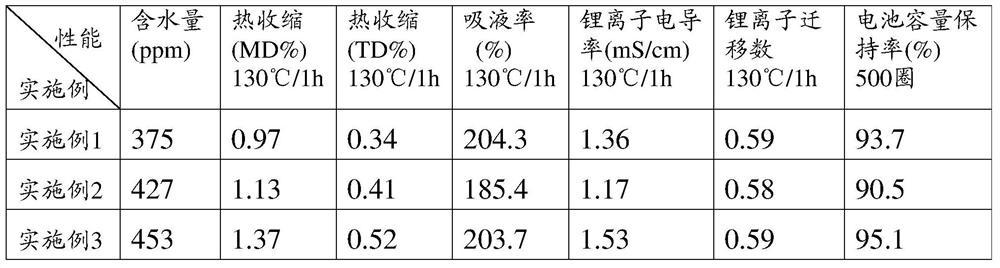

Embodiment 1

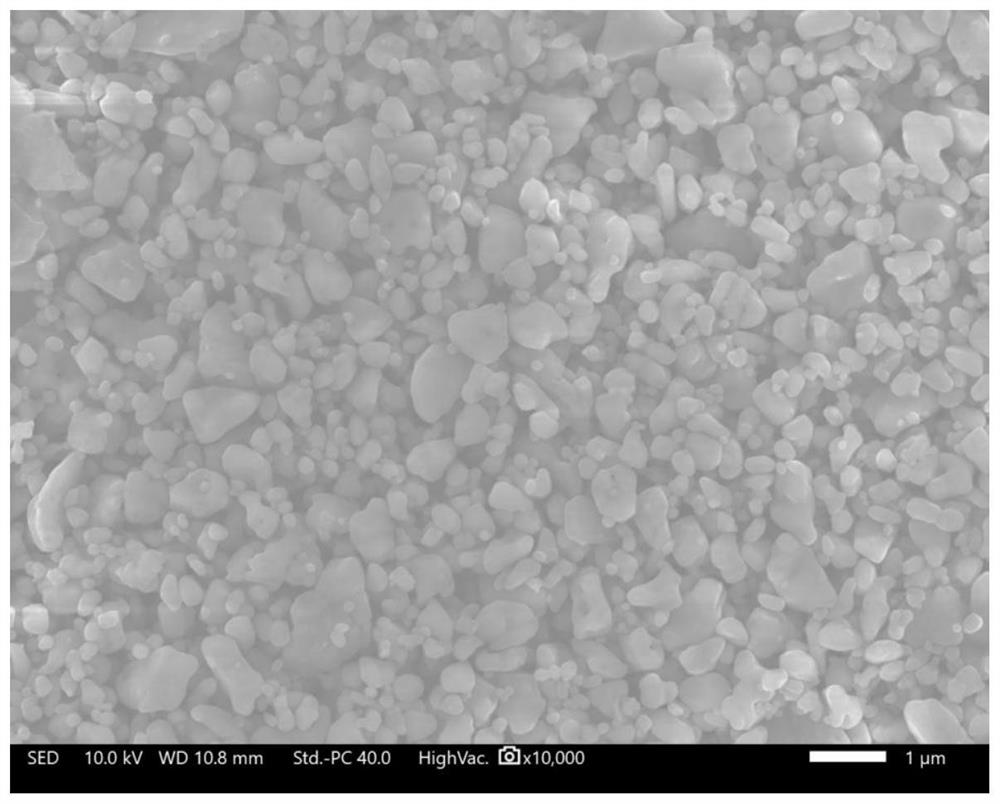

[0037] (1) Aluminum oxide, styrene-maleic anhydride copolymer, and deionized water were mixed and stirred for 3 hours at a mass ratio of 1:0.002:1.2 to obtain a ceramic dispersion.

[0038] (2) Add a water blocking agent to the ceramic dispersion. The water blocking agent is an amphiphilic polymer with a number average molecular weight of 300,000. The amphiphilic polymer includes a hydrophilic end and an lipophilic end, and the hydrophilic end is a methacrylic acid chain. segment, the lipophilic end is a multi-branched alkyl group. The mass of the water-blocking agent is 2% of the mass of the ceramic dispersion to obtain a flocculated ceramic slurry.

[0039] (3) Grind and disperse the flocculated ceramic slurry with a grinder, which uses high-purity zirconia microbeads with a particle size of 0.3 mm for grinding. The speed of the grinder is 1200 rpm, and the particle size of the resulting slurry is less than 2 μm. During the grinding process, a water-blocking agent was added...

Embodiment 2

[0044] (1) Boehmite, polyacrylic acid, sodium dodecylbenzenesulfonate, and deionized water were mixed and stirred for 1 hour at a mass ratio of 1:0.003:0.003:2.3 to obtain a ceramic dispersion.

[0045] (2) Add a water blocking agent to the ceramic dispersion. The water blocking agent is an amphiphilic polymer with a number average molecular weight of 600,000. The amphiphilic polymer includes a hydrophilic end and an lipophilic end, and the hydrophilic end is a methacrylic acid chain. segment, the lipophilic end is a mellitic acid ester group. The mass of the water-blocking agent is 1% of the mass of the ceramic dispersion liquid, and a flocculated ceramic slurry is obtained.

[0046] (3) Grind and disperse the flocculated ceramic slurry with a grinder, which uses high-purity zirconia microbeads with a particle size of 1.2 mm for grinding. The grinder speed is 500 rpm, and the particle size of the obtained slurry is less than 2 μm. During the grinding process, a water blockin...

Embodiment 3

[0051] (1) Magnesium hydroxide, zirconium oxide, sodium aryl naphthalenesulfonate, and deionized water were mixed and stirred for 1.5 hours at a mass ratio of 1:1:0.003:3.6 to obtain a ceramic dispersion.

[0052] (2) Add a water blocking agent to the ceramic dispersion. The water blocking agent is an amphiphilic polymer with a number average molecular weight of 400,000. The amphiphilic polymer includes a hydrophilic end and an lipophilic end, and the hydrophilic end is polymethacrylic acid Ester segment, the lipophilic end is 1,4,5,8-naphthalene tetracarboxylate. The mass of the water-blocking agent is 3% of the mass of the ceramic dispersion liquid, and a flocculated ceramic slurry is obtained.

[0053] (3) Grind and disperse the flocculated ceramic slurry with a grinder, which uses high-purity zirconia microbeads with a particle size of 0.8 mm for grinding. The speed of the grinder is 1500 rpm, and the particle size of the obtained slurry is less than 2 μm. During the grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com