Production process of hydrophobic polyimide film

A technology of polyimide film and production process, which is applied in the field of preparation of modified polyimide film, and can solve problems such as limiting the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare diamine monomer A, and diamine monomer A is made by following steps:

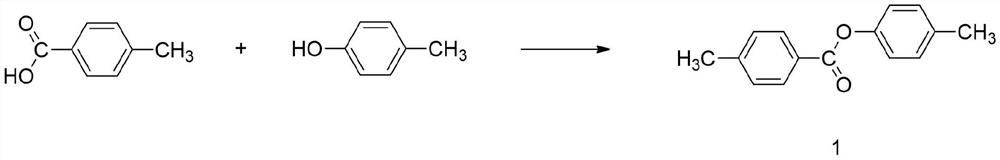

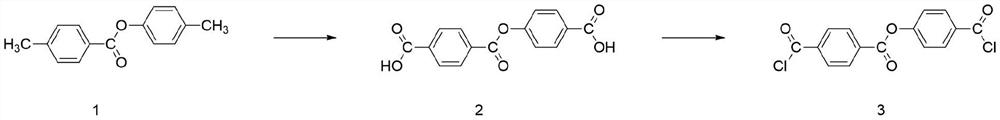

[0032] Step S1: Add p-toluene benzoic acid and p-cresol to the flask, then add p-toluenesulfonic acid and toluene, and react at a temperature of 115°C for 4 hours. After the reaction, the reaction product is cooled to 70°C and transferred to liquid separation funnel, and add a saturated sodium chloride aqueous solution with a temperature of 70 ° C, shake and let stand for 30 minutes to separate layers, add the organic phase to the flask, distill under reduced pressure to remove toluene, and filter to obtain intermediate 1; the p-toluic acid , p-cresol, p-sulfobenzoic acid, and toluene are used in a ratio of 0.05mol: 0.05mol: 1.8g: 45mL;

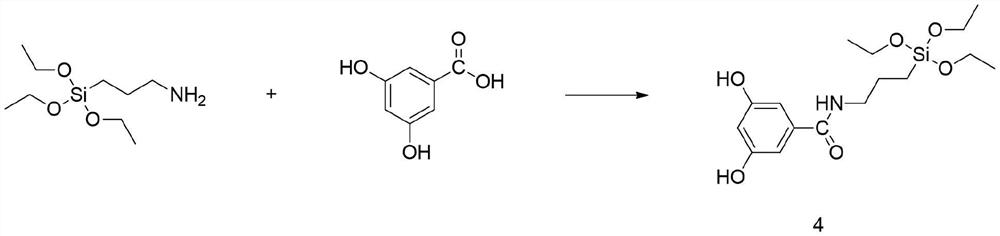

[0033] Step S2: Add intermediate 1 and deionized water to the flask, reflux and add potassium permanganate, reflux for 3 hours to obtain intermediate 2; then add intermediate 2 and deionized water to the flask, add DMF and dichloro Sulfoxide, reflux reactio...

Embodiment 2

[0039] Prepare diamine monomer A, and diamine monomer A is made by following steps:

[0040]Step S1: Add p-toluene benzoic acid and p-cresol to the flask, then add p-toluenesulfonic acid and toluene, and react at a temperature of 117.5°C for 4.5 hours. After the reaction, the reaction product is cooled to 70°C and transferred to a separate Liquid funnel, and add the saturated sodium chloride aqueous solution that the temperature is 70 ℃, shake and stand for 30min to separate layers, add the organic phase to the flask, distill under reduced pressure to remove toluene, and filter to obtain intermediate 1; the p-toluene The dosage ratio of formic acid, p-cresol, p-sulfobenzoic acid and toluene is 0.05mol: 0.05mol: 1.8g: 45mL;

[0041] Step S2: Add intermediate 1 and deionized water to the flask, reflux and add potassium permanganate, reflux for 3 hours to obtain intermediate 2; then add intermediate 2 and deionized water to the flask, add DMF and dichloro Sulfoxide, reflux react...

Embodiment 3

[0047] Prepare diamine monomer A, and diamine monomer A is made by following steps:

[0048] Step S1: Add p-toluene benzoic acid and p-cresol to the flask, then add p-toluenesulfonic acid and toluene, and react at a temperature of 120°C for 5 hours. After the reaction is completed, the reaction product is cooled to 70°C and transferred to liquid separation funnel, and add a saturated sodium chloride aqueous solution with a temperature of 70 ° C, shake and let stand for 30 minutes to separate layers, add the organic phase to the flask, distill under reduced pressure to remove toluene, and filter to obtain intermediate 1; the p-toluic acid , p-cresol, p-sulfobenzoic acid, and toluene are used in a ratio of 0.05mol: 0.05mol: 1.8g: 45mL;

[0049] Step S2: Add intermediate 1 and deionized water to the flask, reflux and add potassium permanganate, reflux for 3 hours to obtain intermediate 2; then add intermediate 2 and deionized water to the flask, add DMF and dichloro Sulfoxide, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com