A kind of preparation method of stable cationic pigment dispersant and stable cationic pigment dispersant

A pigment dispersant and cation technology, applied in the direction of coating, can solve the problems of weak pigment tinting strength and poor coating performance of pigment particles, and achieve the effect of good steric hindrance, good stability and improved conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

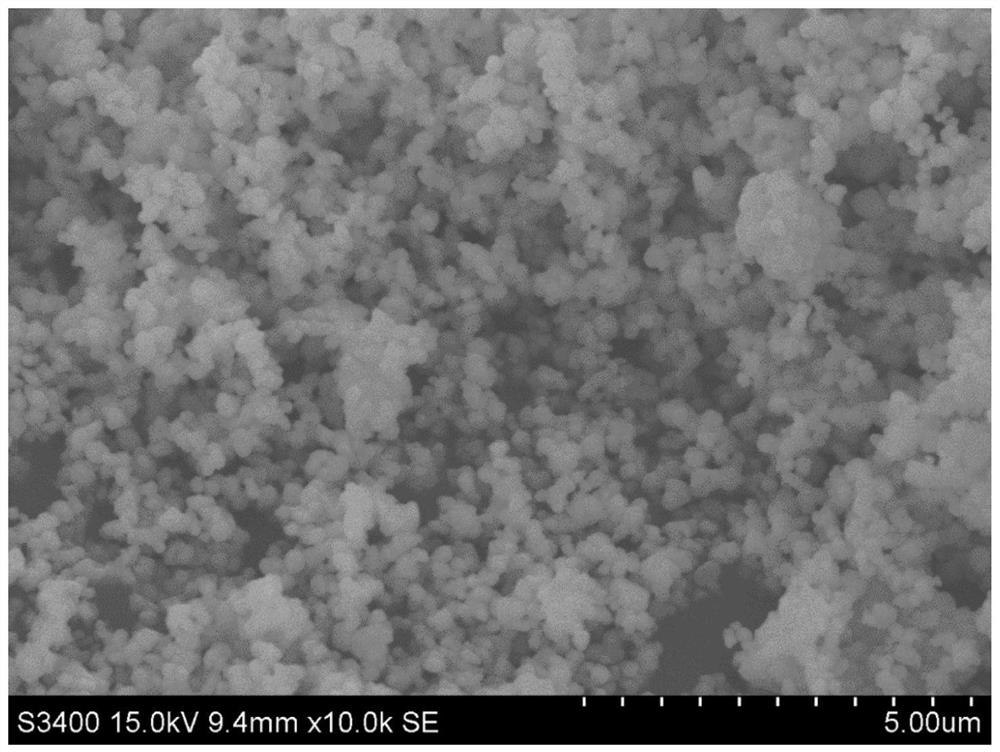

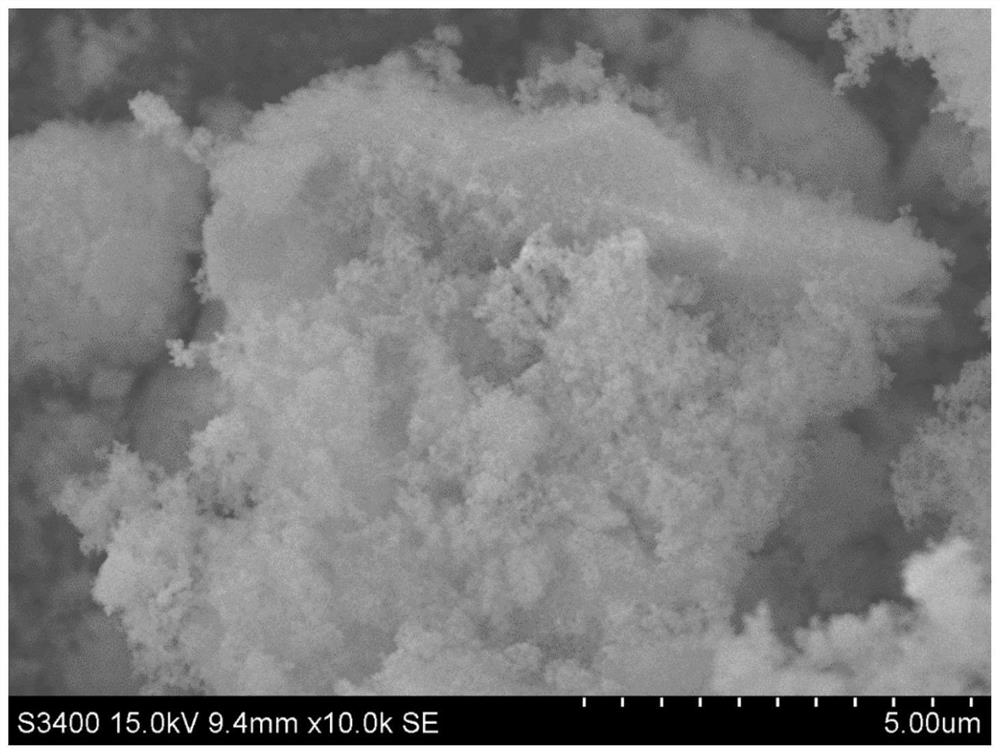

Image

Examples

Embodiment 1

[0043] A stable cationic pigment dispersant and a preparation method thereof are formed by polymerizing the following components, the total mass of the raw materials is 1000 parts, and the components include:

[0044] 10.54 parts of poly-1,2-propylene glycol, 352.27 parts of ethylene oxide, 0.4 parts of the composition of concentrated sulfuric acid with a mass ratio of 3:2 and lithium aluminum tetrahydrogen, 28.75 parts of allyltrimethylammonium chloride, mass ratio It is 2.3 parts of compositions of 1:3 sodium formaldehyde sulfoxylate and sodium metabisulfite, and the mass ratio is 6.5 parts of compositions of 1:1 diisopropyl peroxydicarbonate and benzoyl peroxide, and the mass ratio is 1.1 parts of a composition of 3:2 thioglycolic acid and mercaptopropanol, 5.5 parts of a composition of potassium carbonate and triethanolamine in a mass ratio of 3:1, and the rest are water, and the total mass is 1000 parts.

[0045] A preparation method of a stable cationic pigment dispersan...

Embodiment 2-6

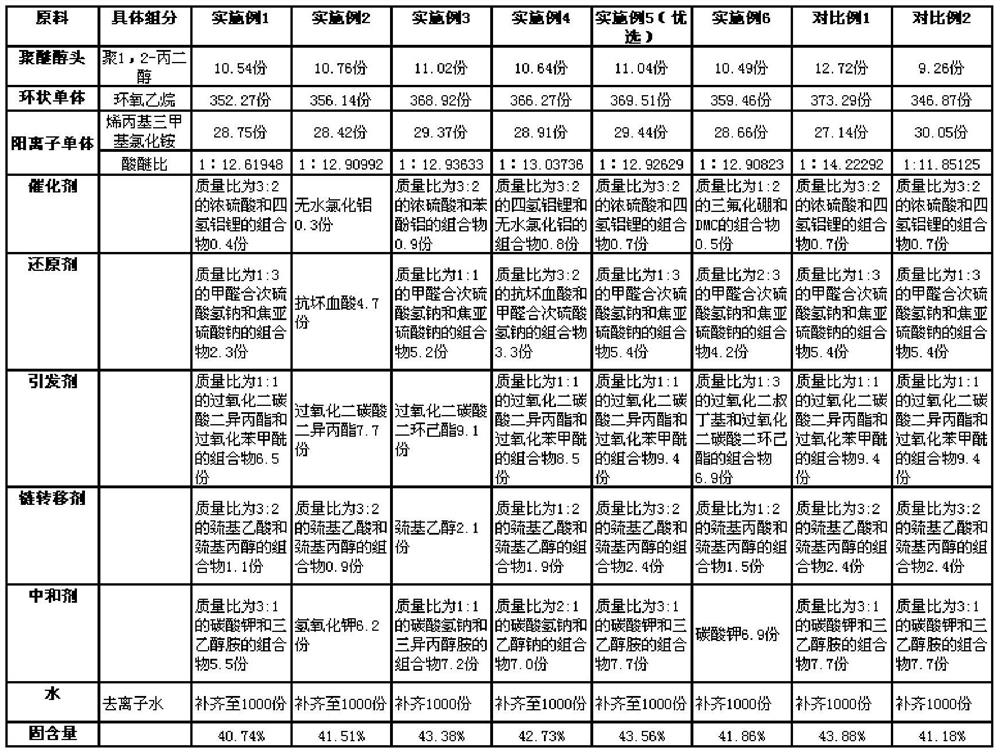

[0051] Examples 2-6 are used to illustrate the preparation method of the stable cationic pigment dispersant of the present invention and the stable cationic pigment dispersant prepared by the method.

[0052] In this example, except that the components and amounts of the raw materials are shown in Table 1, and the parameters in the steps are shown in Table 2, the same method as Stable cationic pigment dispersant, of which Example 5 is the most preferred solution.

[0053] Example 1 is used as a sample for comparison with Example 5 to illustrate the preferred solid content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com