A kind of microcrystalline cellulose modified polyester fiber and preparation method thereof

A technology of microcrystalline cellulose and modified polyester, applied in the field of polyester, can solve the problems of poor hydrophilic properties of polyester fibers, and achieve the effects of improving hydrophilic properties, improving compatibility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

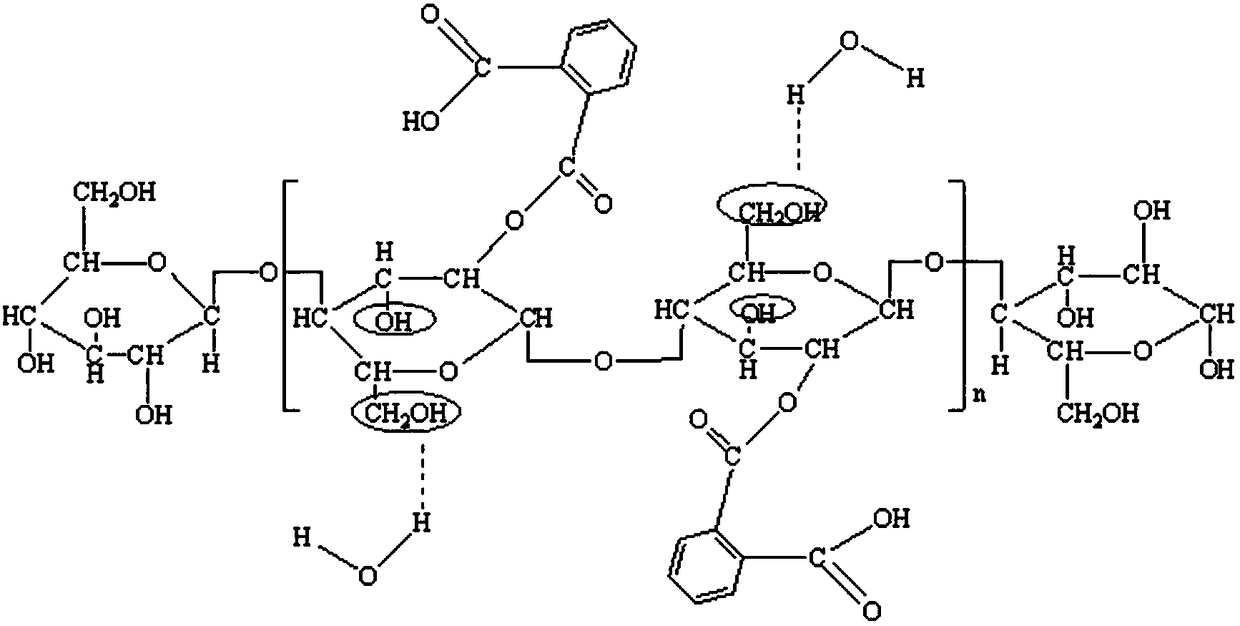

Image

Examples

Embodiment 1

[0046] (1) Preparation and surface modification of cellulose microcrystals:

[0047] Add microcrystalline cellulose to sulfuric acid with a concentration of 10mol / L and mixed acid with phthalic acid to fully decompose microcrystalline cellulose. The molar ratio of sulfuric acid to phthalic acid is 1:0.1; The decomposition reaction was continuously stirred at 100° C. for 10 h, and washed with deionized water to obtain cellulose microcrystals. The dispersion liquid is freeze-dried to obtain phthalic acid-modified cellulose microcrystals with a particle size of 100 nm.

[0048] (2) Cellulose microcrystalline / glycol beating:

[0049] The mass fraction ratio of the surface-modified cellulose crystallites in ethylene glycol prepared in step (1) is 20% and beaten, and phthalic anhydride is added at the same time, and the added phthalic anhydride is surface-modified cellulose 5% of the microcrystalline mass, forming a uniform cellulose microcrystalline slurry.

[0050] (3) In-situ ...

Embodiment 2

[0055] (1) Preparation and surface modification of cellulose microcrystals:

[0056] Add microcrystalline cellulose to the mixed acid of hydrochloric acid and phthalic acid with a concentration of 5mol / L to fully decompose the microcrystalline cellulose. The molar ratio of hydrochloric acid and phthalic acid in the mixed acid is 1:0.5; Under the constant temperature condition of the bath: the constant temperature condition of the oil bath is controlled at 110° C., the decomposition reaction is continuously stirred for 8 hours, and the cellulose microcrystals are obtained by washing with deionized water. The dispersion liquid is freeze-dried to obtain phthalic acid-modified cellulose microcrystals on the surface with a particle size of 150 nm.

[0057] (2) Cellulose microcrystalline / glycol beating:

[0058] The surface-modified cellulose microcrystals are beaten in propylene glycol, and the surface-modified cellulose microcrystals account for 40% of the mass in propylene glyco...

Embodiment 3

[0064] (1) Preparation and surface modification of cellulose microcrystals:

[0065] Add microcrystalline cellulose to the mixed acid of nitric acid and phthalic acid with a concentration of 1mol / L to fully decompose the microcrystalline cellulose. The molar ratio of nitric acid and phthalic acid in the mixed acid is 1:1. Continue to stir and decompose for 5 hours at a constant temperature of 120°C, wash with deionized water to obtain cellulose microcrystals, freeze-dry the dispersion, and obtain surface phthalic acid with a particle size of 200 nm for the cellulose microcrystals. Modified cellulose microcrystals.

[0066] (2) Cellulose microcrystalline / glycol beating:

[0067] Surface-modified cellulose microcrystals are beaten in butanediol, and the mass fraction of cellulose microcrystals in butanediol is 60%; at the same time, phthalic anhydride is added, and the added phthalic anhydride is surface modification 3% of the mass of cellulose crystallites forms a uniform cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com