Polymer used as pesticide dispersant and purpose thereof

A dispersant and polymer technology, applied in the field of polymer synthesis, can solve problems such as thermal storage instability and high viscosity of the system, and achieve the effects of improving electrostatic repulsion, strengthening electrostatic repulsion, and firm adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

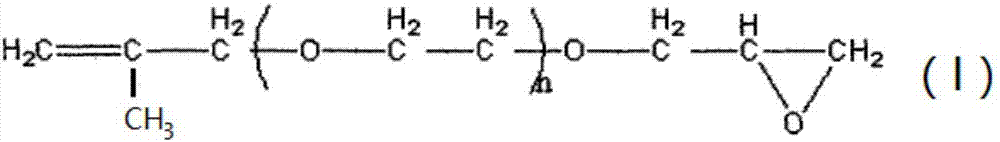

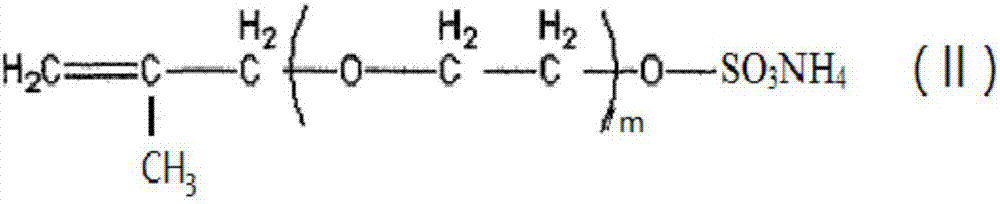

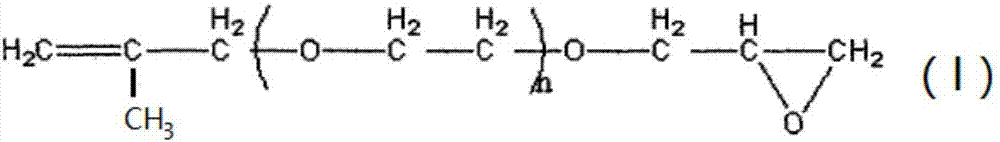

[0029] The polymer used as a pesticide dispersant is composed of the following components in mass percent: 5% glycidyl ether group-terminated methallyl alcohol polyoxyethylene ether (n=9) of the structural formula (I), 10% methyl Allyl alcohol polyoxyethylene ether ammonium sulfate (m=15), 10% methyl methacrylate and 75% methacrylic acid are copolymerized.

[0030] A method for preparing a polymer used as a pesticide dispersant, comprising:

[0031] Step 1: Add 8.83kg of methallyl alcohol polyoxyethylene ether (m=15, molecular weight 732), 1.41kg of sulfamic acid and 0.28kg of urea into the dewatered reactor, wherein methallyl alcohol polyoxyethylene The molar ratio of vinyl ether to sulfamic acid is 1:1.2, and the mass of urea is 19.86% of the mass of sulfamic acid; stir and heat up to 65°C, and keep warm for 4 hours to obtain 10kg of methallyl alcohol polyoxyethylene ether ammonium sulfate;

[0032] Step 2: Add 200kg of water and 5kg of glycidyl ether group-terminated metha...

Embodiment 2

[0039] The polymer used as pesticide dispersant is composed of the following components in mass percentage: 10% glycidyl ether group-terminated methallyl alcohol polyoxyethylene ether (n=15) of structural formula (I), 15% methyl Allyl alcohol polyoxyethylene ether ammonium sulfate (m=23), 15% ethyl methacrylate and 60% methacrylic acid are copolymerized.

[0040] A method for preparing a polymer used as a pesticide dispersant, comprising:

[0041] Step 1: Add 13.86kg of methallyl alcohol polyoxyethylene ether (m=23, molecular weight 1084), 1.36kg of sulfamic acid and 0.34kg of urea into the dewatered reactor, wherein methallyl alcohol polyoxyethylene The molar ratio of vinyl ether to sulfamic acid is 1:1.1, and the mass of urea is 25% of the mass of sulfamic acid; stir and heat up to 70° C., and keep warm for 5 hours to obtain 15 kg of methallyl alcohol polyoxyethylene ether ammonium sulfate;

[0042] Step 2: Add 148kg of water and 10kg of glycidyl ether group-terminated meth...

Embodiment 3

[0049] The polymer used as the pesticide dispersant is composed of the following components in mass percent: 10% glycidyl ether group-terminated methallyl alcohol polyoxyethylene ether (n=15) of structural formula (I), 20% methyl Allyl alcohol polyoxyethylene ether ammonium sulfate (m=15), 15% isooctyl methacrylate and 55% methacrylic acid are copolymerized.

[0050] A method for preparing a polymer used as a pesticide dispersant, comprising:

[0051] Step 1: Add 17.49kg of methallyl alcohol polyoxyethylene ether (m=15, molecular weight 732), 3.01kg of sulfamic acid and 0.75kg of urea into the dewatered reactor, wherein methallyl alcohol polyoxyethylene The molar ratio of vinyl ether to sulfamic acid is 1:1.3, and the mass of urea is 24.91% of the mass of sulfamic acid; stir and heat up to 70°C, and keep warm for 5 hours to obtain 20kg of methallyl alcohol polyoxyethylene ether ammonium sulfate;

[0052] Step 2: Add 160kg of water and 10kg of glycidyl ether group-terminated m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com