Organic electroluminescent compound and uses thereof, and organic electroluminescent device

A technology for electroluminescent devices and compounds, applied in organic chemistry, electro-solid devices, electrical components, etc., can solve the problems of high cost of precious metal raw materials, poor device stability, large power consumption, etc., to achieve cost and price reduction, good space The effect of steric resistance and reducing operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

[0047]

[0048] Under nitrogen protection, add 2,4,6-triisopropylbenzoyl chloride (0.37mol, 100g) and m-bromobenzonitrile (0.75mol, 136.3g) into a 3000ml three-necked flask, and dissolve them in 800ml of dichloromethane , cooled to 0°C, kept stirring for 30 minutes, then added dropwise 200ml of antimony trichloride (0.37mol, 85.4g) dichloromethane solution, raised the temperature to room temperature and stirred for one hour, then heated to reflux for twelve hours, and cooled to room temperature , suction filtration under reduced pressure, the obtained solid was stirred with 3000ml of 28% cold ammonia solution at 0°C for 30 minutes, raised to room temperature and stirred for 3 hours, suction filtered, the solid was washed with 1000ml of water to obtain a white solid, and then heated and dissolved with 1000ml of DMF. Suction filtration under reduced pressure to remove insoluble matter and remove the solvent under reduced pressure to obtain 118.1 g of white crystals with a yiel...

Synthetic example 3

[0050]

[0051] Under nitrogen protection, add 2,4,6-triisopropylbenzoyl chloride (0.37mol, 100g) and m-bromobenzonitrile (0.75mol, 157.3g) into a 3000ml three-necked flask, and dissolve them in 800ml of dichloromethane , cooled to 0°C, kept stirring for 30 minutes, then added dropwise 200ml of antimony trichloride (0.37mol, 85.4g) dichloromethane solution, raised the temperature to room temperature and stirred for one hour, then heated to reflux for twelve hours, and cooled to room temperature , suction filtration under reduced pressure, the obtained solid was stirred with 3000ml of 28% cold ammonia solution at 0°C for 30 minutes, raised to room temperature and stirred for 3 hours, suction filtered, the solid was washed with 1000ml of water to obtain a white solid, and then heated and dissolved with 1000ml of DMF. Suction filtration under reduced pressure to remove insoluble matter and remove the solvent under reduced pressure to obtain 146.1 g of white crystals with a yiel...

Synthetic example 4

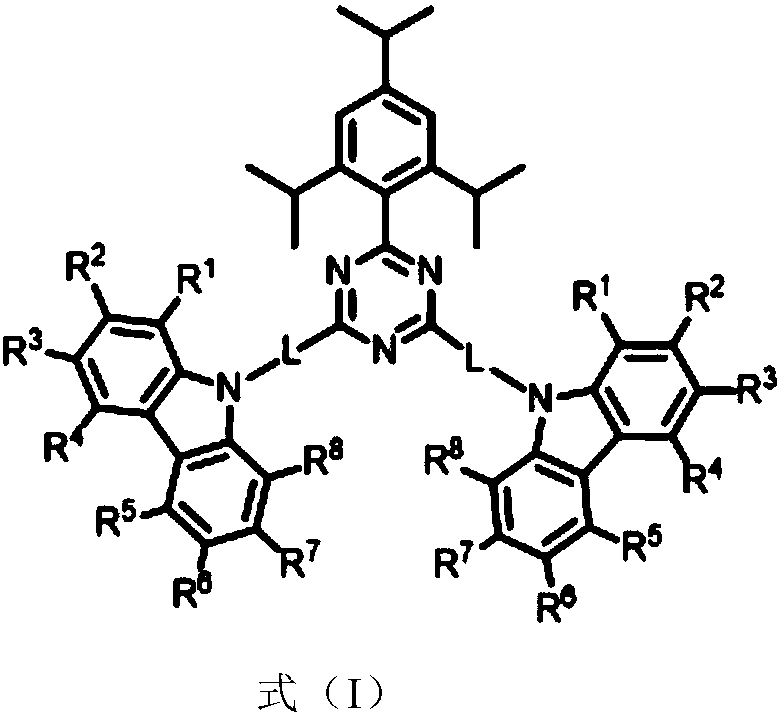

[0052] Synthesis Example 4: Synthesis of Compound C1

[0053]

[0054] Under nitrogen protection, add raw materials M1 (10g, 16.9mmol), carbazole (7.1g, 42.2mmol), potassium phosphate (10.7g, 50.7mmol) into a 500ml three-necked flask, dissolve in 300ml toluene, replace with nitrogen three times, and then add PD 2 (dba) 3 (0.2g, 1%), x-phos (0.3g, 3%), heat up to 110°C, react for 12 hours, cool down to room temperature, add water, dry the organic phase, remove the organic solvent under reduced pressure, dry silica gel By chromatography, 8.0 g of the product was obtained with a yield of 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com