High magnification hard water resistant dispersant, and preparation method and application thereof

A dispersant and hard water technology, applied in the field of polymer compound preparation, can solve the problems of high product yield, inability to effectively reduce the relative molecular weight distribution width, uneven molecular weight distribution of the dispersant, etc., and achieve stable dispersion performance and narrow molecular weight distribution range. , the effect of preventing particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

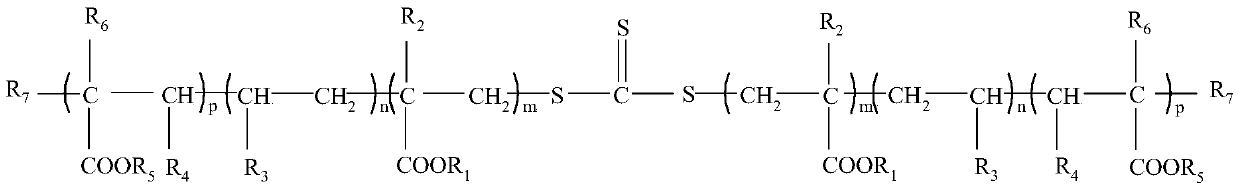

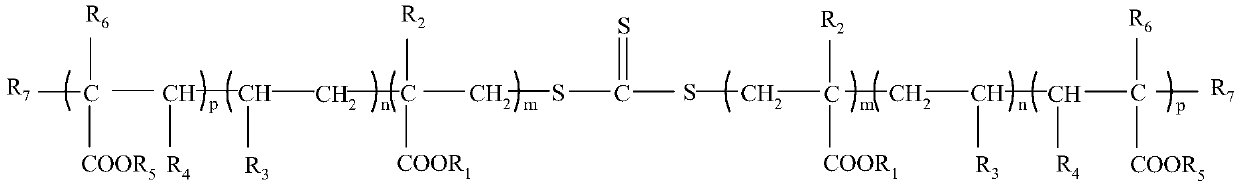

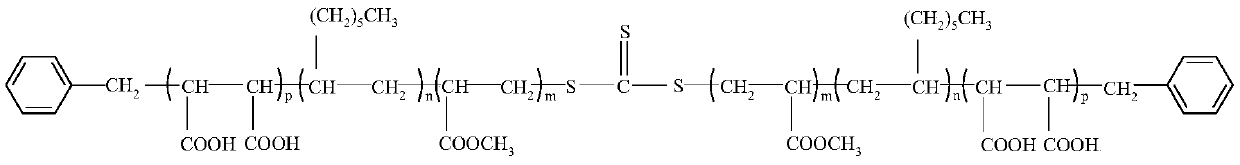

[0063] The specific structural formula of the polymer dispersant PC-1 provided in the present embodiment is as follows:

[0064]

[0065] The preparation steps of above-mentioned polymer dispersant PC-1 are as follows:

[0066] (1) Use acetone as a solvent to configure dimethyl azobisisobutyrate solution (0.38g dimethyl azobisisobutyrate is dissolved in 25g acetone), and a mixed solution of methyl acrylate and 1-octene (acrylic acid Methyl ester 43g, 1-octene 22.4g);

[0067] (2) Add 3.9 g of S, S-dibenzyl trithiocarbonate, 19.6 g of maleic anhydride, 0.13 g of Dimethyl azodiisobutyrate and 60g of acetone, in N 2 Under the atmosphere, heat to 62°C and continue stirring for 55 minutes;

[0068] (3) The constant flow pump works, and starts to add dropwise the dimethyl azobisisobutyrate solution and the mixed solution of methyl acrylate and 1-octene, and the dimethyl azobisisobutyrate solution is added dropwise in 3 hours. The mixed solution of methyl acrylate and 1-octene...

Embodiment 2

[0073] The specific structural formula of the polymer dispersant PC-2 provided in the present embodiment is as follows:

[0074]

[0075] The preparation steps of above-mentioned polymer dispersant PC-2 are as follows:

[0076] (1) Use butanone as a solvent to configure azobisisobutyronitrile solution (0.37g dimethyl azobisisobutyrate is dissolved in 30g butanone), and a mixed solution of methyl methacrylate and styrene (methyl Methyl acrylate 50g, styrene 20.8g);

[0077] (2) Add 4.3 g of S, S'-bis(2-methyl-2-propionyl) trithiocarbonate, 18g of acrylic acid, 0.12g of azobisisobutyronitrile and 65g of methyl ethyl ketone, in N 2 Under atmosphere, heat to 70°C and continue to stir for 1h;

[0078] (3) The constant flow pump works, and starts to drip the mixed solution of azobisisobutyronitrile solution and methyl methacrylate and styrene, and the azobisisobutyronitrile solution is added dropwise in 3.5 hours, and methyl methacrylate and The mixed solution of styrene was ad...

Embodiment 3

[0083] The specific structural formula of the polymer dispersant PC-3 provided in the present embodiment is as follows:

[0084]

[0085] The preparation steps of above-mentioned polymer dispersant PC-3 are as follows:

[0086] (1) take isopropanol as solvent configuration dibenzoyl peroxide solution (0.36g dibenzoyl peroxide is dissolved in 25g isopropanol), and the mixed solution of acrylate-2-hydroxyethyl ester and acrylamide ( 2-hydroxyethyl acrylate 58g, acrylamide 10.6g);

[0087] (2) Add 4.1 g of S, S'-bis(α-hydroxyethyl isobutyrate) trithiocarbonate, 19.5 g Itaconic acid, 0.12g of dibenzoyl peroxide and 70g of isopropanol, in N 2 Under atmosphere, heat to 85°C and continue to stir for 30 minutes;

[0088] (3) The constant flow pump works, and starts to drop dibenzoyl peroxide solution and a mixed solution of 2-hydroxyethyl acrylate and acrylamide. The dibenzoyl peroxide solution is added dropwise in 4 hours, and the acrylic acid-2 - The mixed solution of hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com