Machine-made sand regulator of alcohol ether modified carboxylic acid polymer and preparation method of machine-made sand regulator

A technology of carboxylic acid polymer and sand conditioner, applied in the field of engineering and construction, can solve the problems of poor workability of concrete, sharp edges and corners of machine-made sand, poor gradation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

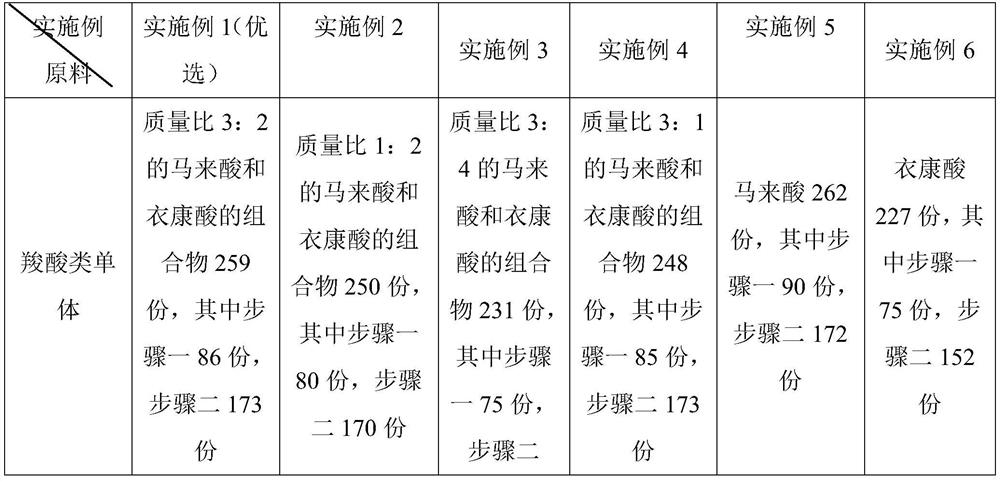

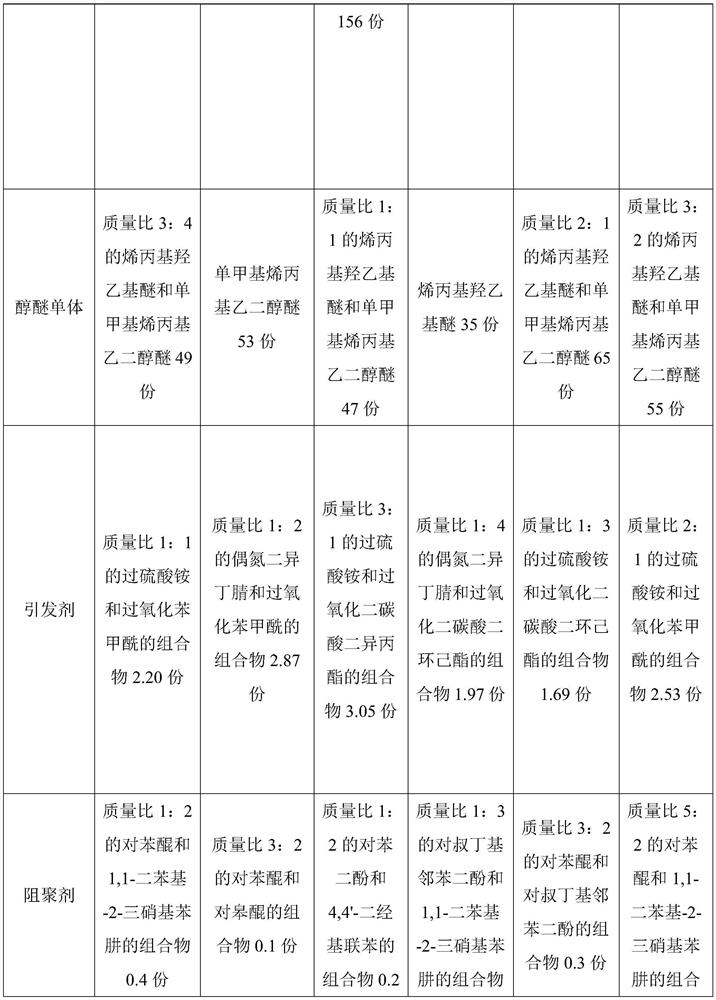

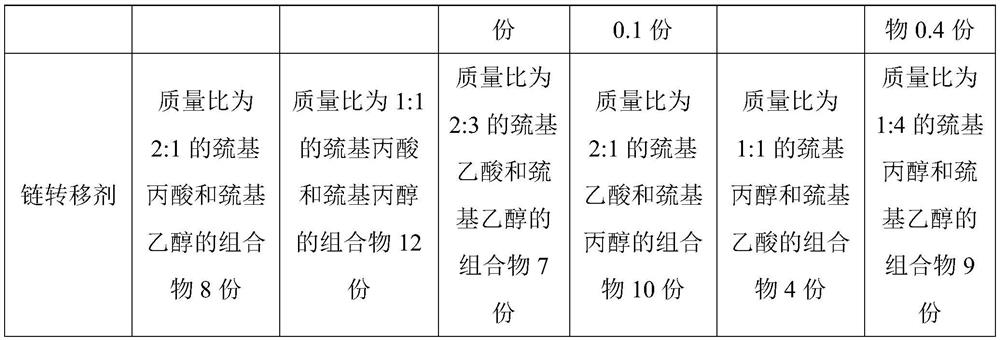

Embodiment 1

[0031] A machine-made sand conditioner for alcohol ether modified carboxylic acid polymers, the machine-made sand conditioner for alcohol ether modified carboxylic acid polymers is prepared from the following components:

[0032] 259 parts of the composition of maleic acid and itaconic acid with a mass ratio of 3:2;

[0033] 49 parts of allyl hydroxyethyl ether and monomethallyl glycol ether with a mass ratio of 3:4;

[0034] 2.20 parts of a composition of ammonium persulfate and benzoyl peroxide with a mass ratio of 1:1;

[0035] 0.4 parts of a composition of p-benzoquinone and 1,1-diphenyl-2-trinitrophenylhydrazine at a mass ratio of 1:2;

[0036] 8 parts of compositions of mercaptopropionic acid and mercaptoethanol with a mass ratio of 2:1;

[0037] The rest is water, with a total mass of 1000 parts.

[0038] The preparation method comprises the following steps:

[0039] Step 1: Add 86 parts of a composition of maleic acid and itaconic acid with a mass ratio of 3:2, 49 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com