A kind of preparation method and application of inorganic pigment and filler aqueous dispersant

The technology of a water-based dispersant and its production method is applied in the field of water-based dispersant for inorganic pigments and fillers and the production of water-based dispersants for inorganic pigments and fillers. Particle flocculation and other problems, to achieve good steric hindrance, good dispersion and viscosity reduction effect, high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

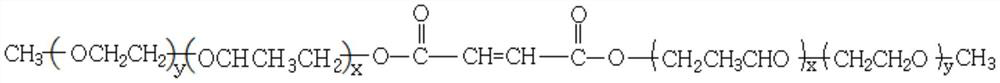

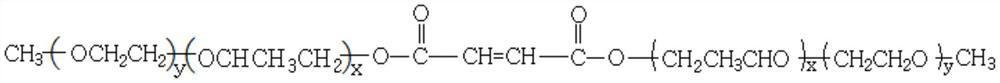

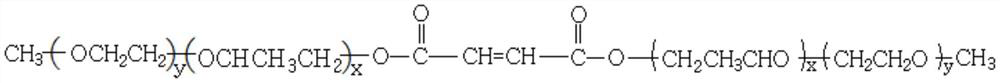

Image

Examples

Embodiment 1

[0044]The first solution is obtained by mixing the total mass of deionized water with monomeric acrylic acid and maleimide in a mass ratio of 1.5:1, and ammonium persulfate and deionized water are mixed into a 5% solution to form a second solution, A third solution was formed by making up a 5% solution of ferrous sulfate and deionized water. The first solution, the second solution and the third solution were added dropwise to the unsaturated block polyether, the dropwise addition was continued at 65°C and the reaction was carried out. the fourth solution. Triethylamine is added to the fourth solution, the fourth solution is neutralized to pH 6 to 8, and the inorganic pigment and filler aqueous dispersant is obtained.

[0045] In this embodiment, x is 7 and y is 25 in the unsaturated block polyether; the molar ratio of acrylic acid, maleimide and unsaturated block polyether is 1.6:0.8:1; oxidation-reduction The mass of ammonium persulfate in the system initiator accounts for ...

Embodiment 2

[0047] The first solution is obtained by mixing the total mass of deionized water with monomer maleic acid and methacrylamide in a mass ratio of 2.2:1, and potassium persulfate and deionized water are mixed into a 10% solution to form a second solution , a 10% solution of potassium bisulfite and deionized water was prepared to form a third solution. The first solution, the second solution and the third solution were added dropwise to the unsaturated block polyether, and the dropwise addition and reaction were continued at 82 °C. the fourth solution. A potassium hydroxide 30% (w%) solution was added to the fourth solution, the fourth solution was neutralized to pH 6 to 8, and the inorganic pigment and filler aqueous dispersant was obtained.

[0048] In this embodiment, x is 3 and y is 15 in the unsaturated block polyether; the molar ratio of maleic acid, methacryloyl and unsaturated block polyether is 3.0:1.8:1; oxidation- In the reduction system initiator, the mass of potass...

Embodiment 3

[0050] The first solution was obtained by mixing the total mass of deionized water with methacrylic acid and N-octylmaleimide in a mass ratio of 0.8:1, and sodium persulfate and deionized water were mixed into a 7% solution to form For the second solution, a 7% solution of sodium thiosulfate and deionized water was prepared to form a third solution. The first solution, the second solution and the third solution were added dropwise to the unsaturated block polyether, and the dropwise addition and reaction were continued at 73°C. the fourth solution. A sodium hydroxide 30% (w%) solution is added to the fourth solution, the fourth solution is neutralized to pH 6 to 8, and the inorganic pigment and filler aqueous dispersant is obtained.

[0051] In this embodiment, x is 11 and y is 36 in the unsaturated block polyether; the molar ratio of methacrylic acid, N-octylmaleimide and unsaturated block polyether is 4.5:3.2 : 1; the mass of sodium persulfate in the oxidation-reduction sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com