Dispersion agent used for pesticide suspension concentrate and preparation method thereof

A technology for suspending and dispersing agent, applied in the field of dispersing agent and its preparation, can solve the problems of difficulty in improving the long-term stability of the preparation, easy growth of product crystals, poor product hydrophilicity, etc. The effect of resistance and bounce reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

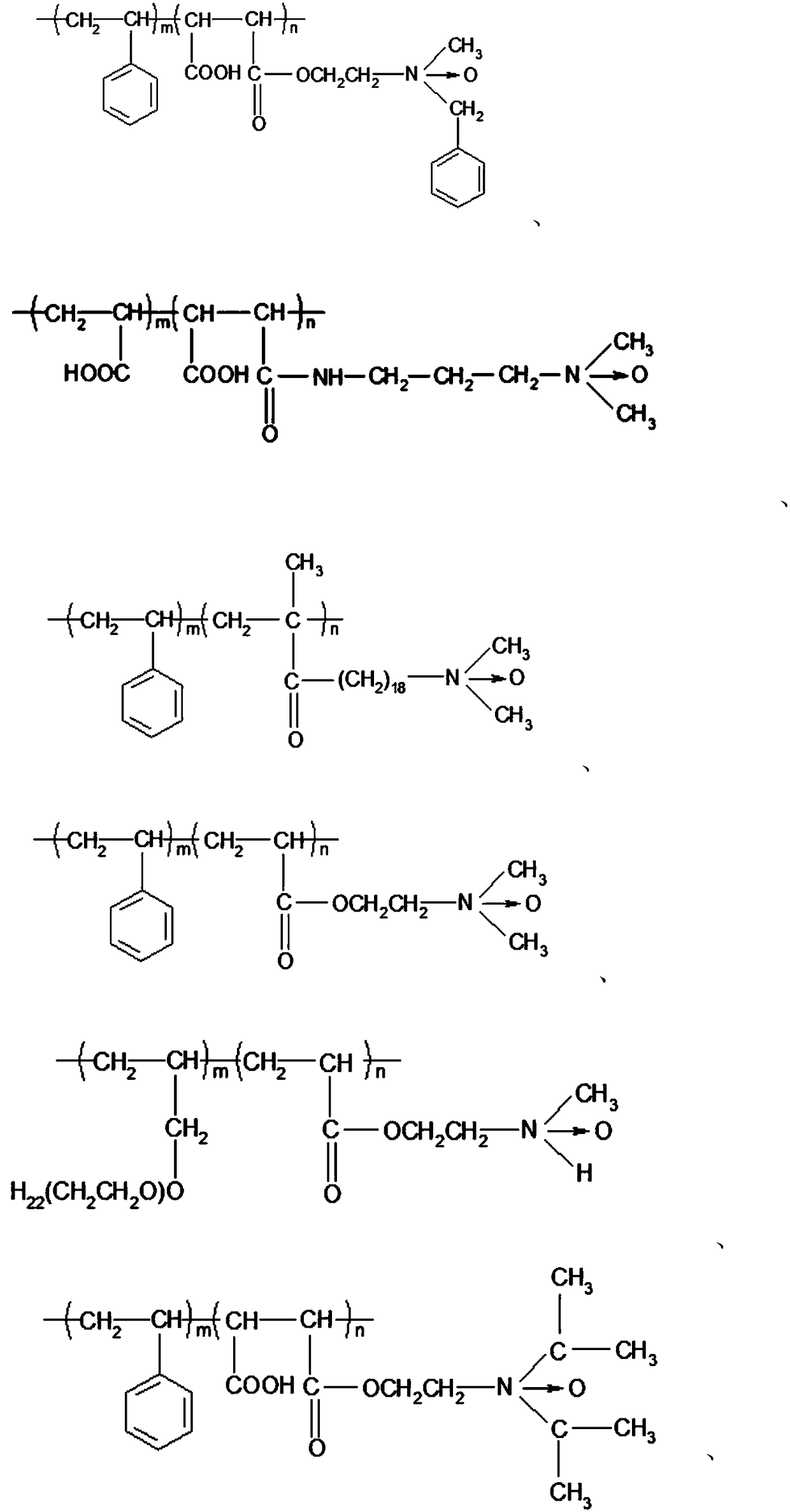

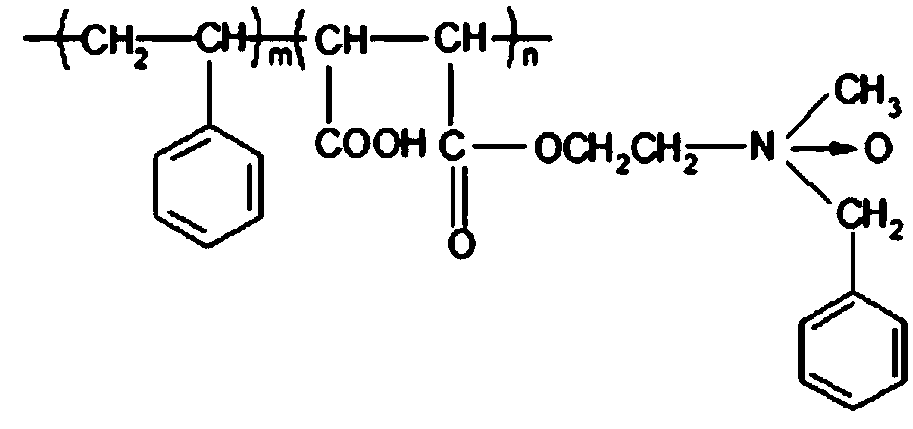

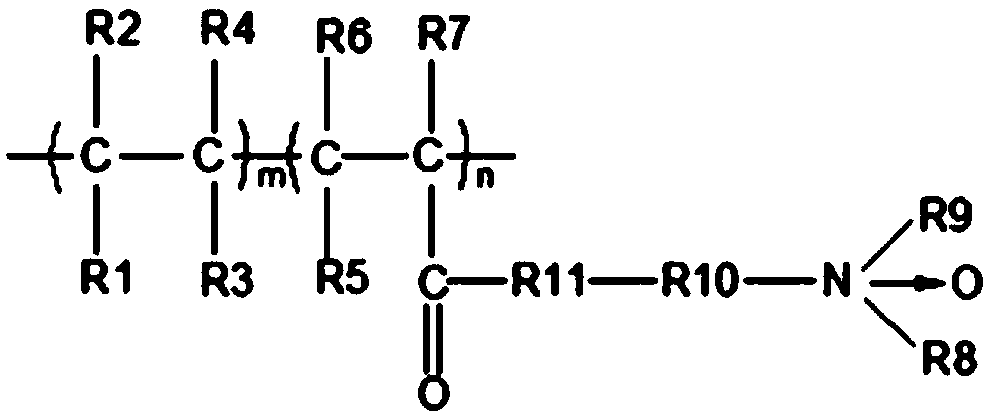

Method used

Image

Examples

Embodiment 1

[0040] First add 200.0g of SMA 1000 (CRAY VALLEY, styrene-maleic anhydride copolymer) and 1.1g of propionic acid to a four-neck flask equipped with a stirrer, thermometer and reflux condenser, then heat to 60°C and stir for 30min ; Then use a constant pressure dropping funnel to add 20.0g of N-benzyl-N-methylethanolamine to a four-necked flask, heat up to 90°C and reflux for 4h under stirring, and remove water under reflux; Adding a sodium hydroxide solution with a mass concentration of 30% neutralizes the reaction system to a pH of 6.1, adding metered deionized water to adjust the solid content (mass) to 40%, then adding 4.2g of hydrogen peroxide dropwise, then at 60°C Continue to react for 4h to obtain polymer dispersant PC-1.

[0041]

Embodiment 2

[0043] First add 280.0g of SMA EF-40 (CRAY VALLEY, styrene-maleic anhydride copolymer) and 13.4g of tetrabutyl titanate in a four-necked flask with stirrer, thermometer and reflux condenser, then heat Stir at 60°C for 30min; then add 56.0g of N,N-diisopropylethanolamine into the four-neck flask using a constant pressure dropping funnel, raise the temperature to 110°C and reflux for 6h under stirring conditions, and react under reflux Remove water; then add a mass concentration of 30% potassium hydroxide solution to neutralize to a pH of 7.8, add metered deionized water to adjust the solid content to 40%, then add 19.6g of hydrogen peroxide dropwise, and then continue the reaction at 90°C for 6h, that is Obtain polymer dispersant PC-2.

[0044]

Embodiment 3

[0046] First add 220.0 g of maleic anhydride and acrylic acid copolymer (Beijing Guangyuan Yinong Chemical Co., Ltd.) and 4.1 g of p-toluenesulfonate in a four-necked flask with a stirrer, a thermometer and a reflux condenser. acid, then heated to 60°C and stirred for 30min; then added 35.2g of dimethylpropylenediamine to a four-neck flask using a constant pressure dropping funnel, raised the temperature to 95°C and refluxed the reaction for 5h under stirring, and Remove water under reflux reaction; then add ammonia solution to neutralize to pH 6.5, add metered deionized water to adjust the solid content to 40%, add 12.3g hydrogen peroxide dropwise, and then continue to react at 70°C for 6h to obtain a polymer dispersant PC-3.

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com