Preparation method of nano zirconium oxide powder dispersing agent and nano zirconium oxide powder dispersing agent

A technology of nano-zirconia and dispersant, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problem of large specific surface area and total surface energy, large particles that are easy to agglomerate nano-powder, and particle size of inorganic nano-powder minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention provides a kind of preparation method of nano zirconia powder dispersant, it is characterized in that, this method comprises:

[0019] Synthesize alcohol head and cyclic monomer into polyether under the action of catalyst;

[0020] making the polyether react with a small hydrophilic monomer under the action of a reducing agent, an initiator, and a chain transfer agent to prepare a polyether dispersant; and

[0021] Add neutralizing agent in described polyether dispersant, make nano zirconia powder dispersant,

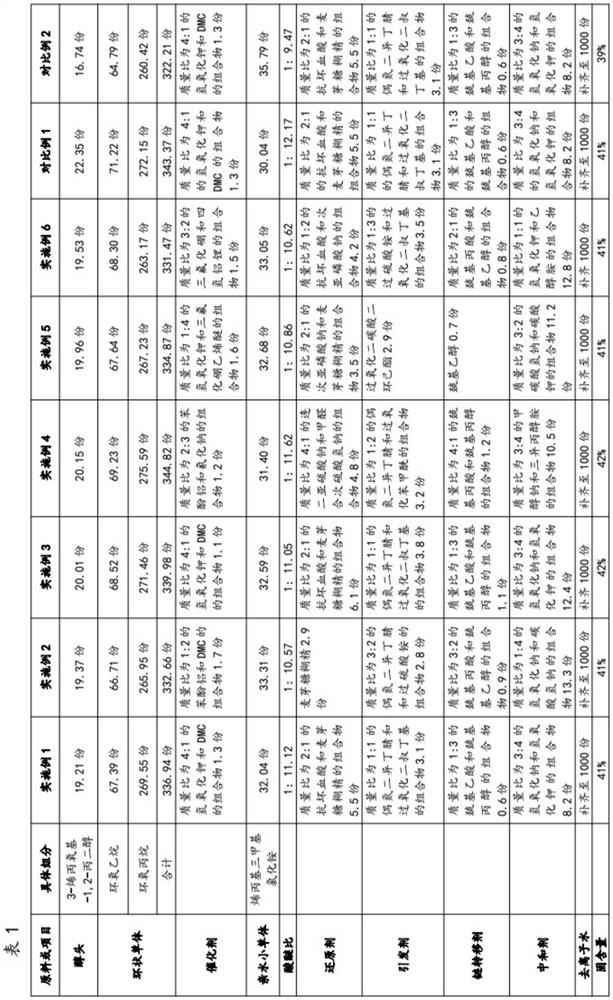

[0022] Based on the total amount of raw materials being 1000 parts by mass, the amount of each raw material is: 19.17-20.18 parts by mass of alcohol head, 329.45-346.79 parts by mass of cyclic monomer, 1.1-1.7 parts by mass of catalyst, and 31.38-33.43 parts by mass of small hydrophilic monomer parts, 2.5-6.1 parts by mass of reducing agent, 2.4-3.9 parts by mass of initiator, 0.6-1.2 parts by mass of chain transfer agent, 7.9-13.4 parts by...

Embodiment 1

[0044] Example 1 is used to illustrate the preparation method of the nano-zirconia powder dispersant of the present invention and the nano-zirconia powder dispersant prepared by the method.

[0045] The nano zirconia powder dispersant of this embodiment is formed by the polymerization of the following components, the total mass of raw materials is 1000 parts, and the consumption of each component is as follows:

[0046] 19.21 parts of 3-allyloxy-1,2-propanediol

[0047] Ethylene oxide 67.39 parts

[0048] Propylene oxide 269.55 parts

[0049] 1.3 parts of the composition of potassium hydroxide and DMC that mass ratio is 4:1

[0050] Allyltrimethylammonium chloride 32.04 parts

[0051] 5.5 parts of the composition of ascorbic acid and maltodextrin with a mass ratio of 2:1

[0052] 3.1 parts of a composition of azobisisobutyronitrile and di-tert-butyl peroxide with a mass ratio of 1:1

[0053] 0.6 parts of the composition of thioglycolic acid and mercaptopropanol with a mas...

Embodiment 2-6

[0061] Examples 2-6 are used to illustrate the preparation method of the nano zirconia powder dispersant of the present invention and the nano zirconia powder dispersant prepared by the method.

[0062] In this example, except that the components and amounts of the raw materials are as shown in Table 1, and the parameters in the steps are as shown in Table 2, the same method as in Example 1 is used to prepare the samples of Examples 2-6. Nano zirconia powder dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com