A kind of desulfurization wastewater degelling agent and its preparation method and application

A technology of desulfurization wastewater and debonding agent, which is applied in the fields of fine chemical industry and ceramic industry, can solve the problems of degumming effect, etc., and achieve the effect of small initial viscosity, good economic and environmental benefits, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

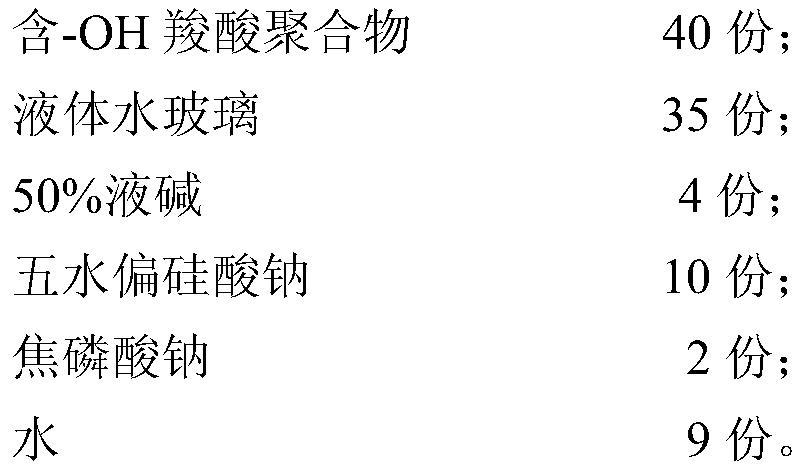

[0049] Formulation (with mass parts):

[0050]

[0051] According to the above formulation ratio, liquid water glass, 50% liquid base (aqueous solution of aqueous sodium hydroxide), sodium hydroxide, sodium hydroxide, and water were mixed with water at 150 r / min, and then slowly The -OH carboxylic acid polymer was added, and the mixture was allowed for 10 min to uniform at a speed of 150 r / min while adding, and then slowly added sodium pentewater-biased silicate, and the mixture was mechanically stirred at a speed of 150 r / min while adding 10 min to uniform. To produce desulfurization wastewater extracts.

[0052] Take 200g Yingcai Soil BC01, add 0.6% of the desulfurization wastewater gel, 12.8 g of desulfurization wastewater and 115.1 g of water, i.e., a water moratorium, and produce a uniform mud in the planetary ball mill. Then, the mud viscosity was measured, and the initial viscosity of the mud was 37.6 s; after standing for 5 min, the viscosity was measured, the slur...

Embodiment 2

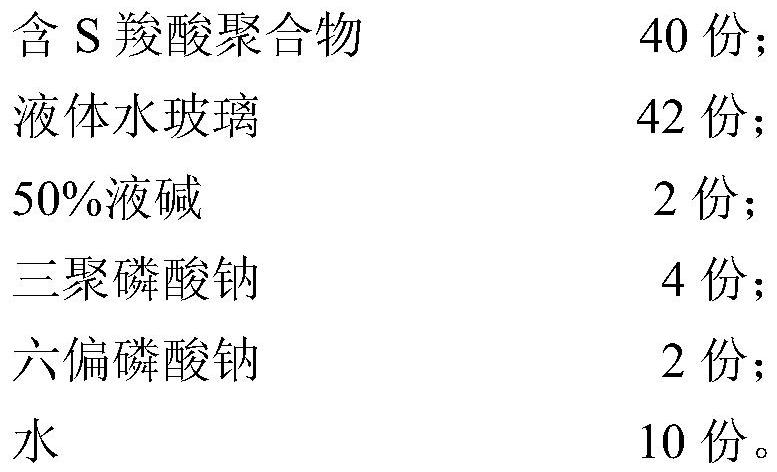

[0054] Formulation (with mass parts):

[0055]

[0056] According to the above formulation ratio, the liquid water glass, 50% liquid base, sodium tripolyphosphate and water were first mixed, and the mixture was stirred at 150 r / min to uniform; then the S-carboxylic acid polymer was slowly added, and when added The mixture is mechanically stirred at 150 r / min to uniform; finally sodium hexaphosphate is slowly added, and the mixture is mechanically stirred at 150 r / min at a speed of 10 min to uniform, and the desulfurization wastewater extract is obtained.

[0057] Take 200g Yingcai Soil BC01, add 0.5% of the desulfurization wastewater extractant, 12.8 g of desulfurization wastewater and 115.1 g of water, i.e., a water grinding, and a uniform mud. Then the mud was coated with a -4 cup to measure the slurry viscosity, the initial viscosity of the mud was 47.5 s; after standing for 5 min, the viscosity was measured, the slurry viscosity was 87.4, and the thixotropy index was 1...

Embodiment 3

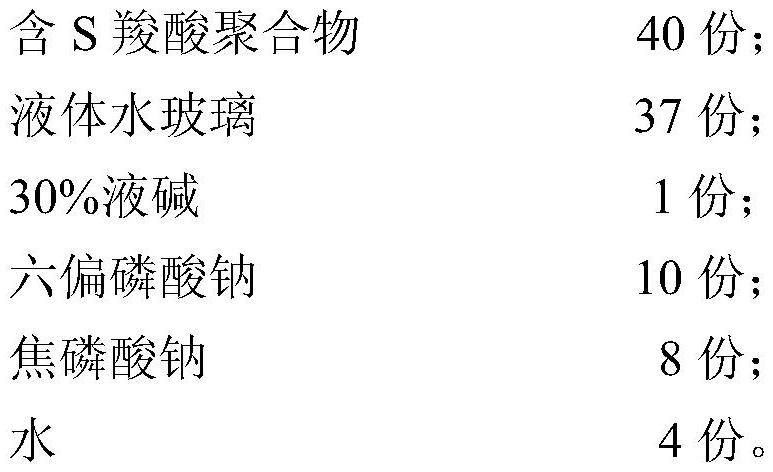

[0059] Formulation (with mass parts):

[0060]

[0061] According to the above formulation ratio, liquid water glass, 30% liquid base, pyrophosphate and water are mixed, and the mix is mechanically stirred; then the S carboxylic acid polymer is slowly added, and the side is added while adding; The mixture is mechanically stirred at 150 r / min to uniform, and the desulfurization wastewater extract is obtained while adding.

[0062] Take 200g Yingcai Soil BC01, add 0.5% of the desulfurization wastewater extractant, 12.8 g of desulfurization wastewater and 115.1 g of water, i.e., a water grinding, and a uniform mud. Then the mud was applied to the -4 cup to measure the viscosity of the mud, and the initial viscosity of the mud was 48.8 s; after standing for 5 min, the viscosity was measured, the slurry viscosity was 87.5s, and the thixotropy index was 1.793.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com