Quadripolymer dispersant and preparation method thereof

A dispersant and polymer technology, which is applied in the field of tetrapolymer dispersant and its preparation, can solve the problems of weak ionization, lack of heterocyclic lipophilic groups, and environmental protection, and achieve good affinity, good adsorption performance, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

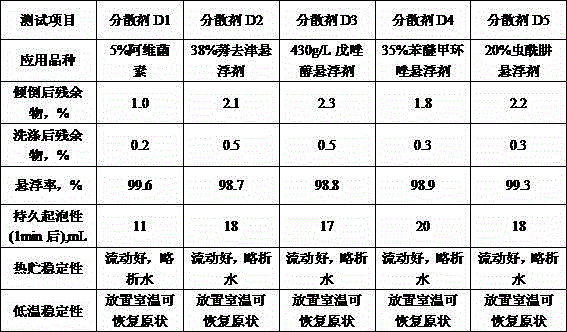

Examples

Embodiment 1

[0017] The preparation of embodiment 1 dispersant D1

[0018] (1) Add 160kg of water, 104kg of ether, and 80kg of methallyl alcohol polyoxyethylene ether into a reaction kettle equipped with a stirrer, thermometer, condenser and dropping equipment (the number of polyoxyethylene repeating units is 53±4.5, that is The molecular weight is 2400±200), 80kg hydroxyethyl methacrylate, 24kg styrene, 24kg sodium styrene sulfonate, heating while stirring;

[0019] (2) When the temperature rises to 80°C, add 27kg of 3.7% sodium persulfate solution dropwise for 1.0h, and keep warm for 2h after the addition;

[0020] (3) Cool to room temperature and adjust the pH to 6.5 with sodium hydroxide, which is the dispersant D1 of the present invention.

[0021] The number-average relative molecular weight of the dispersant measured by gel permeation chromatography is 23,000.

Embodiment 2

[0022] The preparation of embodiment 2 dispersant D2

[0023] In Example 1, methallyl alcohol polyoxyethylene ether (the number of polyoxyethylene repeating units is 53±4.5, that is, the molecular weight is 2400±200) is changed to allyl alcohol polyoxyethylene ether (the number of polyoxyethylene repeating units is 53±4.5 4.5, that is, the molecular weight is 2400±200), and other things remain unchanged, it is the dispersant D2 of the present invention.

[0024] The number-average relative molecular weight of the dispersant measured by gel permeation chromatography is 22,000.

Embodiment 3

[0025] The preparation of embodiment 3 dispersant D3

[0026] In Example 1, the ether was changed to ethanol, and 80kg of methallyl alcohol polyoxyethylene ether (the number of polyoxyethylene repeating units was 53±4.5, that is, the molecular weight was 2400±200) was changed to 40kg of methallyl alcohol polyoxyethylene ether (the number of polyoxyethylene repeating units is 53±4.5, that is, the molecular weight is 2400±200), 40kg of allyl alcohol polyoxyethylene ether (the number of polyoxyethylene repeating units is 53±4.5, that is, the molecular weight is 2400±200), other things remain unchanged, It is the dispersant D3 of the present invention.

[0027] The number-average relative molecular weight of the dispersant measured by gel permeation chromatography is 22,500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com