Liquid crystal composition and liquid crystal display element or liquid crystal display device

A technology for liquid crystal compositions and compounds, which can be applied to liquid crystal materials, instruments, chemical instruments and methods, etc., and can solve problems such as uneven display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] The preparation method of liquid crystal composition comprises the following steps:

[0097] (1) Arrange the liquid crystal monomers in order;

[0098] (2) Place the stainless steel beaker on the balance, and put the monomer into the stainless steel beaker with a spoon;

[0099] (3) adding liquid crystal monomers according to the required weight in turn;

[0100] (4) Place the stainless steel beaker with the liquid crystal monomer on the magnetic stirring apparatus to heat and melt;

[0101] (5) After most of the mixture in the stainless steel beaker is melted, a magnetic rotor is added to the stainless steel beaker, the mixture is stirred evenly, and the liquid crystal composition is obtained after cooling to room temperature.

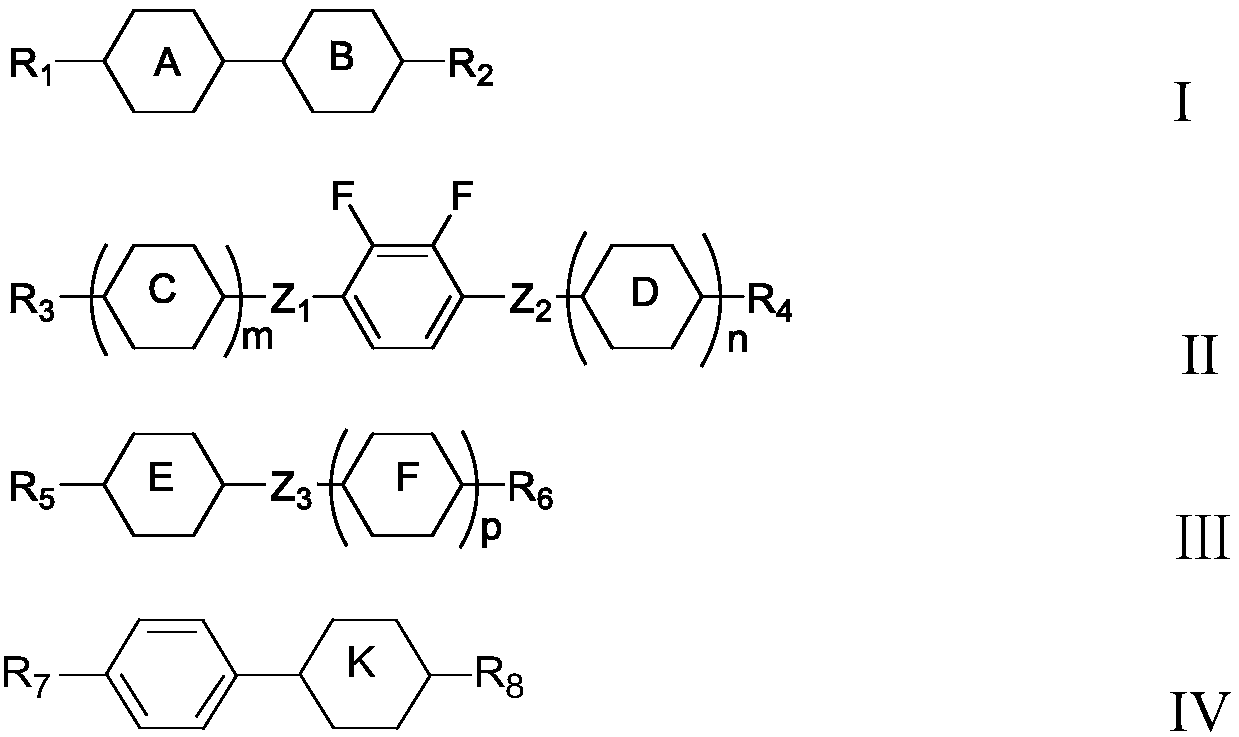

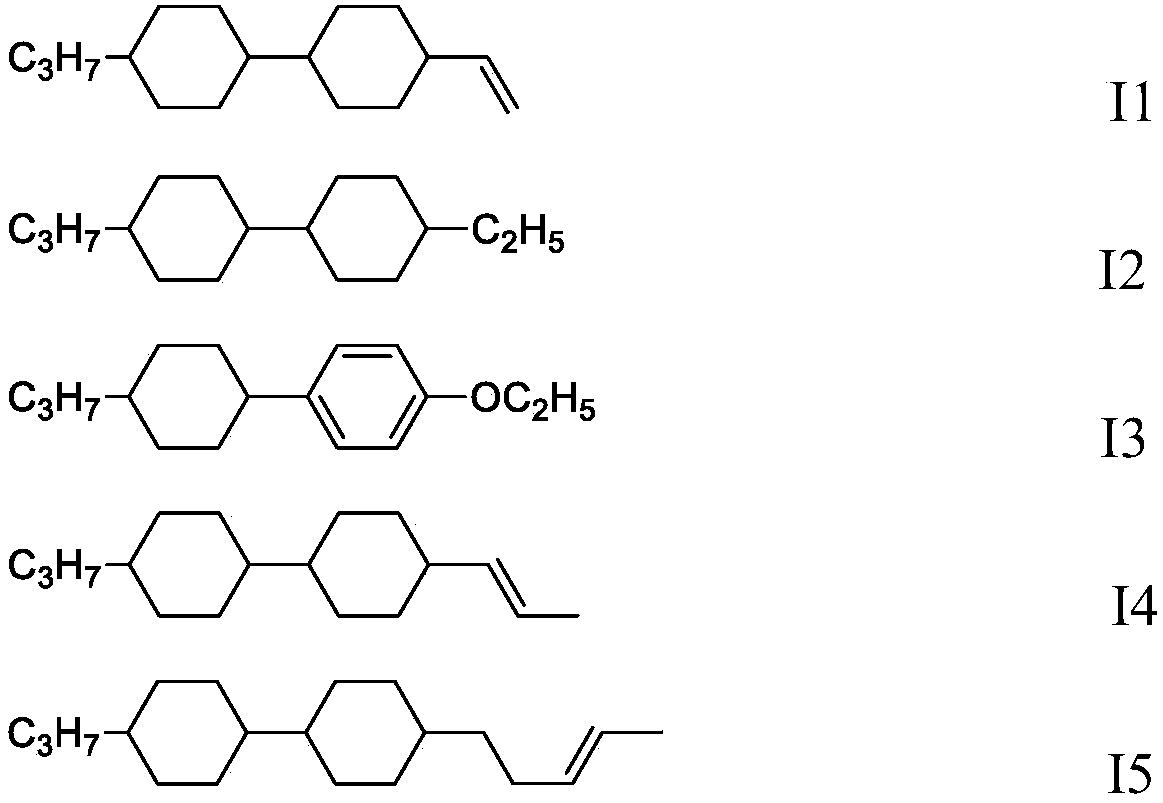

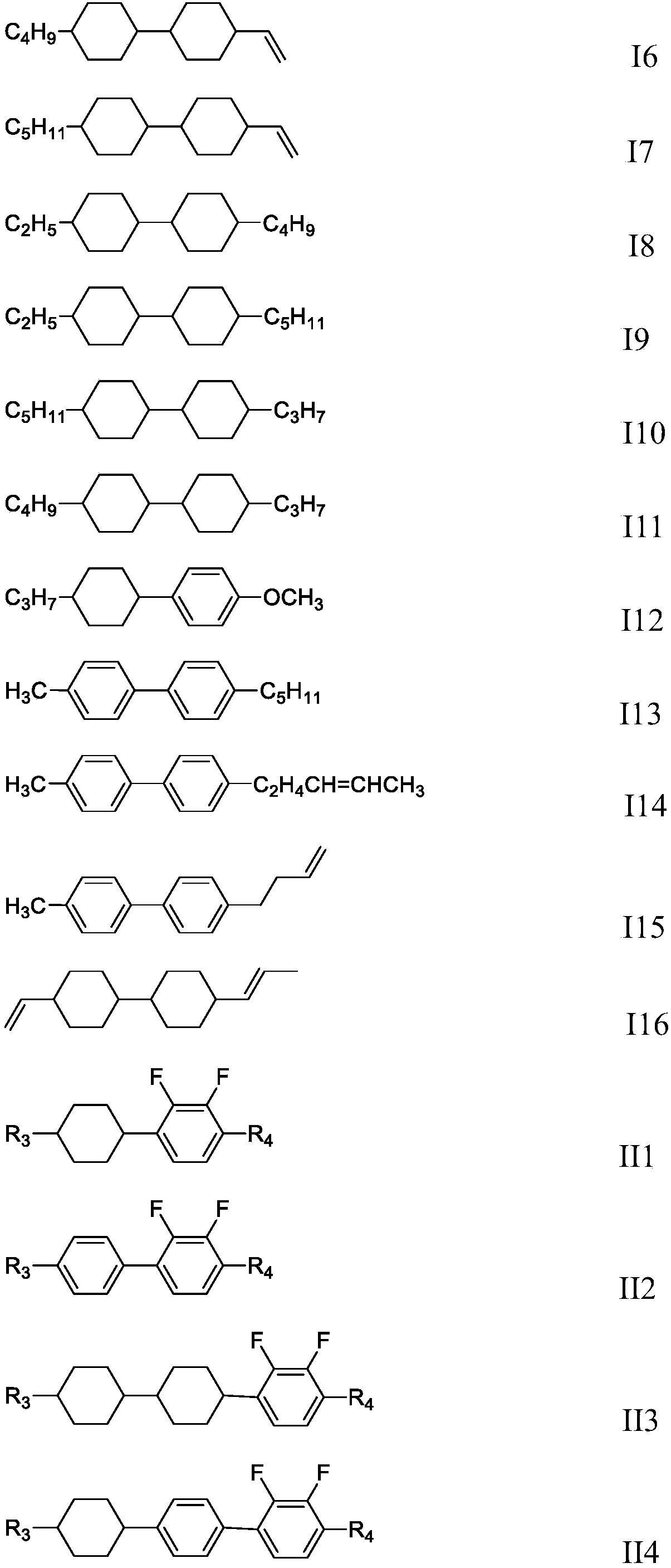

[0102] The structure of the liquid crystal monomer in the embodiment of the present invention is represented by a code, and the code representation methods of the liquid crystal ring structure, terminal group, and linking group are shown in T...

Embodiment 1

[0113] The formula and corresponding properties of the liquid crystal composition are shown in Table 3 below.

[0114] Table 3 The formula and corresponding performance of the liquid crystal composition of embodiment 1

[0115]

[0116]

[0117] The liquid crystal composition provided in Example 1 is polymerized through UV irradiation, and the ultraviolet irradiation intensity is 64mW / cm 2 , the wavelength is 365nm, the irradiation time is 200s, and the conversion rate of the compound represented by formula III as a reactive mesogen (RM) is 30%. The formula for calculating the conversion rate of RM is:

[0118]

[0119] The liquid crystal composition provided in Example 1 has a low viscosity, can realize rapid response, and has moderate dielectric anisotropy Δε, moderate optical anisotropy Δn, and high stability to heat and light. Improving the conversion rate of the reactive mesogen (RM) of the compound represented by formula III by one or more compounds represente...

Embodiment 2

[0121] The formula and corresponding properties of the liquid crystal composition are shown in Table 4 below.

[0122] Formulation and corresponding performance of the liquid crystal composition of table 4 embodiment 2

[0123]

[0124] The liquid crystal composition provided in Example 2 is polymerized through UV irradiation, and the ultraviolet irradiation intensity is 64mW / cm 2 , the wavelength is 365nm, the irradiation time is 200s, and the conversion rate of the compound shown in formula III as reactive mesogen (RM) is 35%.

[0125] The compound shown in formula IV16 is added to the liquid crystal composition provided in Example 2. The compound shown in formula IV16 is a bis-ether structure, which has a larger conjugation and an absorption spectrum closer to the ultraviolet band than the compound with a mono-ether structure. The liquid crystal composition absorbs more energy, which is more conducive to the polymerization of RM and improves the conversion rate of RM. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com