Multi-objective optimization intelligent operation control prediction method for new power supply trains

A multi-objective optimization and operation control technology, applied in non-electric variable control, two-dimensional position/course control, vehicle position/route/altitude control, etc., can solve the problems of less available data, long modeling time, and model accuracy Does not support direct use in actual scenarios and other issues to achieve good predictions and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with drawings and embodiments.

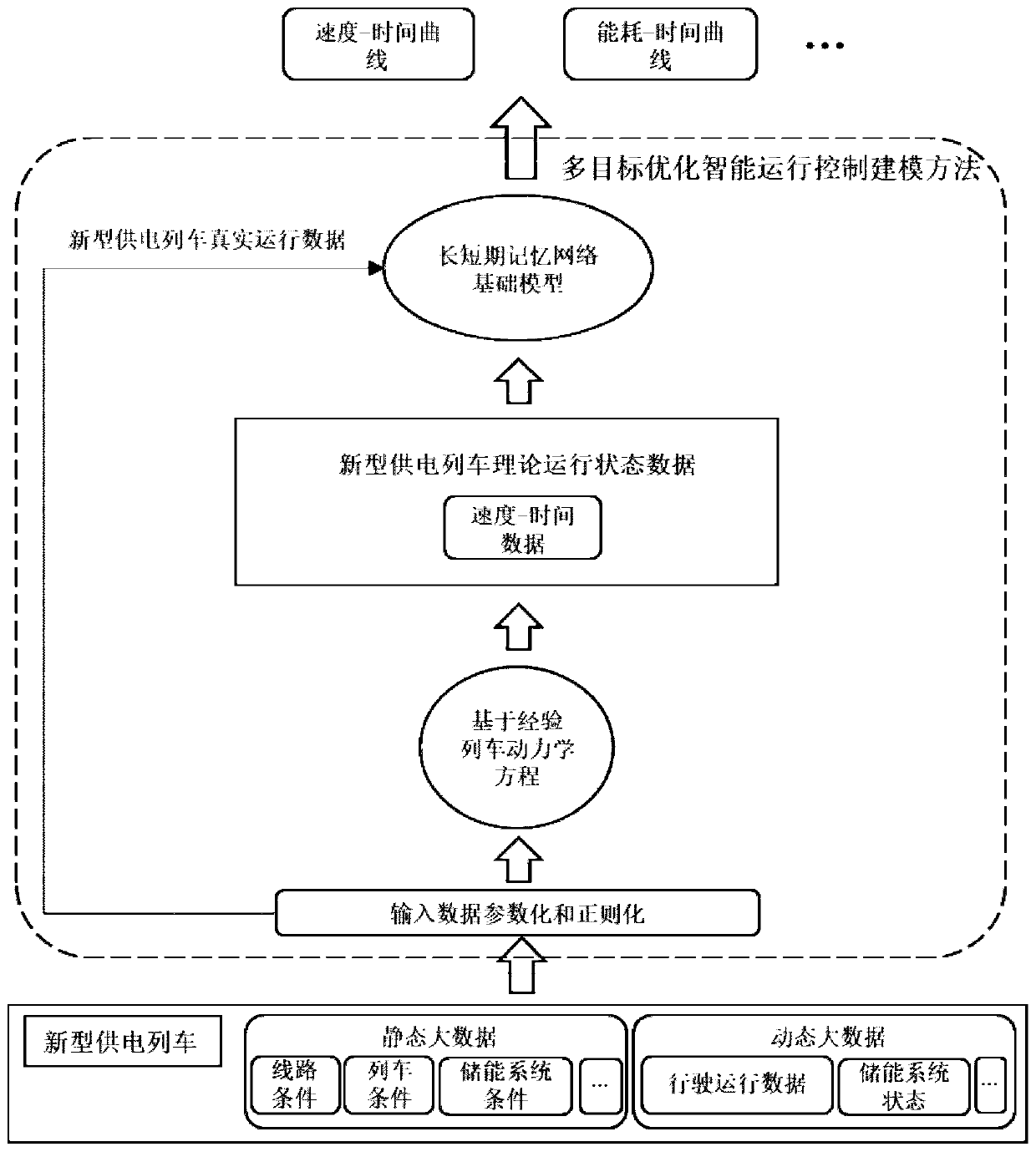

[0051] Such as figure 1 Shown, the embodiment of the present invention and its implementation work process are as follows:

[0052] 1) Obtain the original data from the static / dynamic big data of the new power supply train, then perform parameterization / regularization to obtain standardized data, and then normalize the standardized data to obtain train information sequence data;

[0053] Static and dynamic big data are specifically:

[0054] 1.a) Static line condition data vector P={p 1 ,p 2 ,p 3 ,p 4 ,p 5}, respectively for the slope p 1 , curve p 2 , train position p 3 , the deployment position of the induction coil p 4 , charging capacity p 5 ;

[0055] The static train condition data vector B={b 1 ,b 2 ,b 3 ,b 4}, respectively the maximum passenger capacity b 1 , vehicle weight b 2 , maximum acceleration b 3 , maximum deceleration b 4 ;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com