LED display module structure

A display module and display panel technology, which is applied to instruments, identification devices, etc., can solve the problems of low structural strength of the backplane, affecting the use of the LED display screen, and easy damage to the backplane, so as to enhance stability, reduce stress concentration, The effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

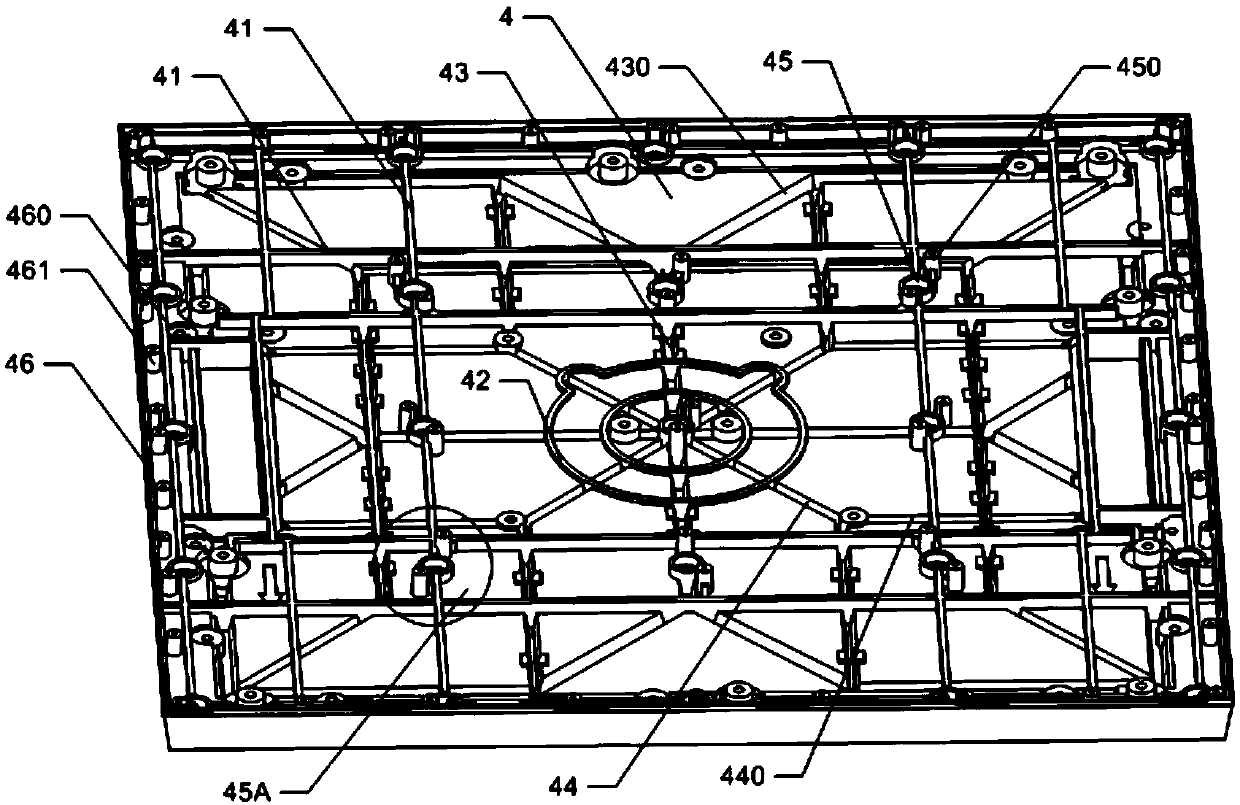

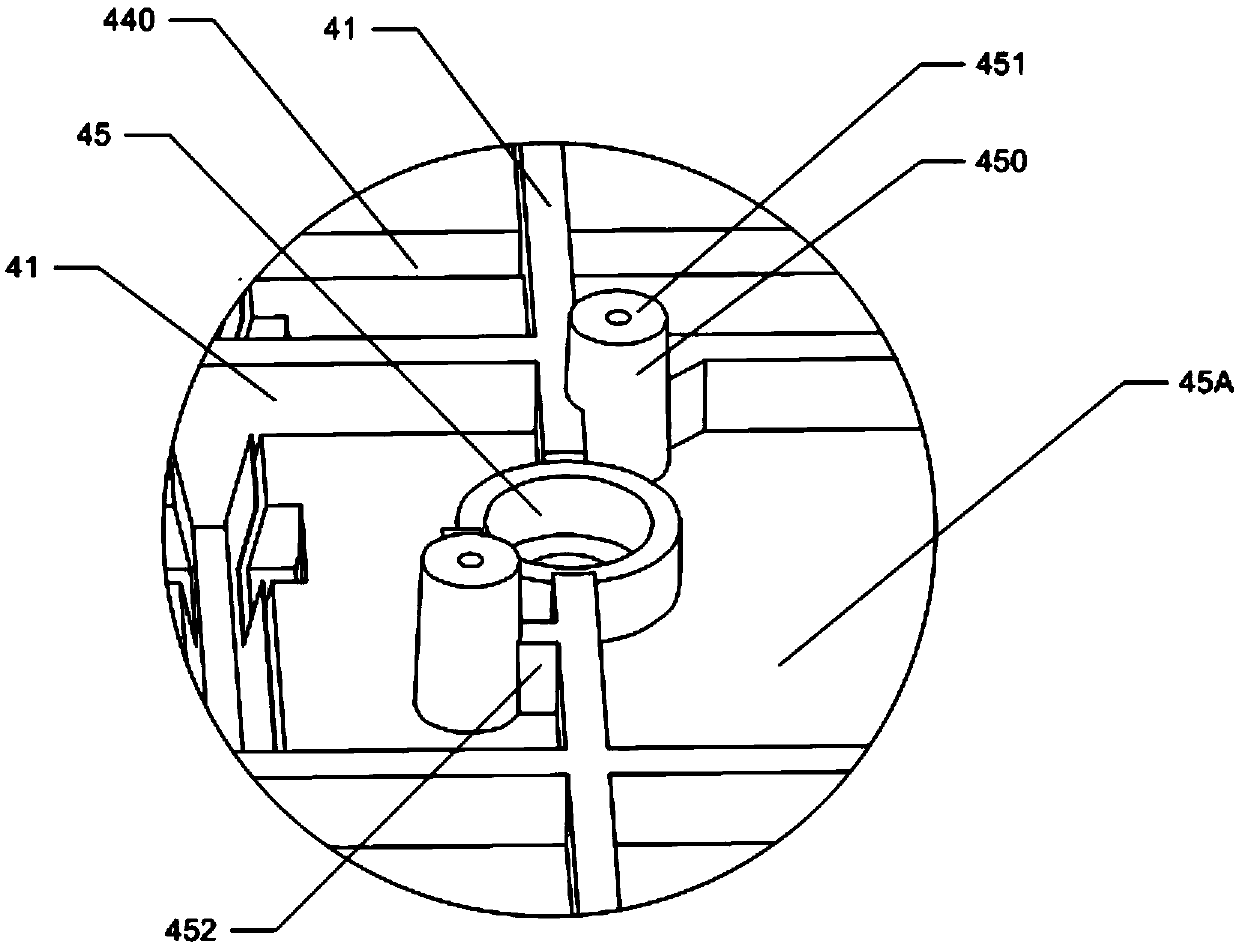

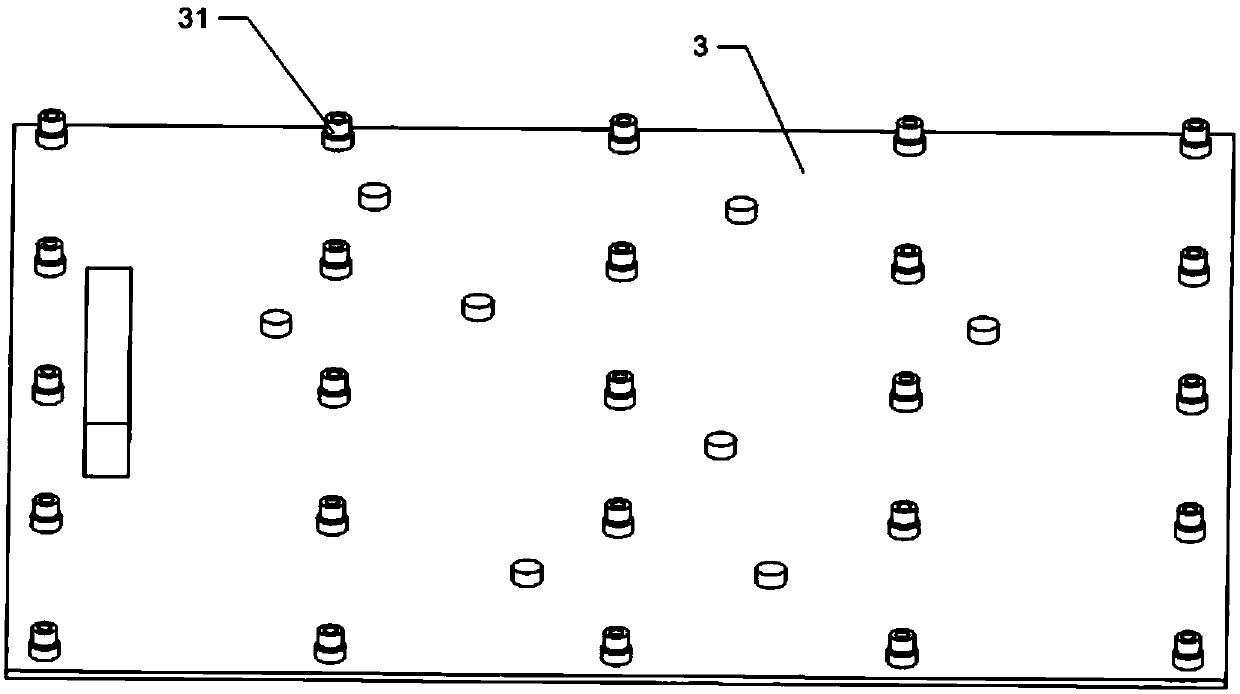

[0022] like figure 1 As shown in -4, the present invention proposes an LED display module structure, including an LED display panel 3 and a backplane 4 arranged below the LED display panel 3, and the backplane 4 is provided with a plurality of reinforcing ribs 41 and a plurality of unloading grooves; wherein, the plurality of reinforcing ribs 41 are arranged in a manner uniformly distributed horizontally and vertically. There are three positioning connection holes 31 columns, and the inner surface of the back plate 4 is also provided with a plurality of positioning installation hole columns 45 corresponding to the position of the positioning connection hole 31 columns, and the plurality of positioning installation hole columns 45 are respectively arranged on the reinforcement On rib 41.

[0023] Since the reinforcing rib 41 is provided on the backboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com