Multi-tank rolling spring cleaning machine

A rolling and washing machine technology, applied in the field of washing machines, can solve the problems of difficult cleaning, unsuitability for enterprises, high maintenance costs, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

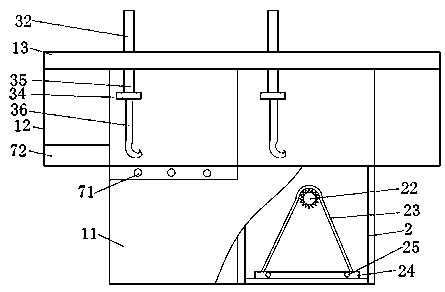

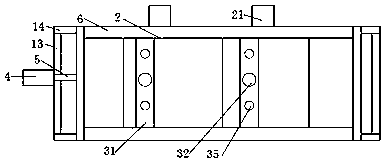

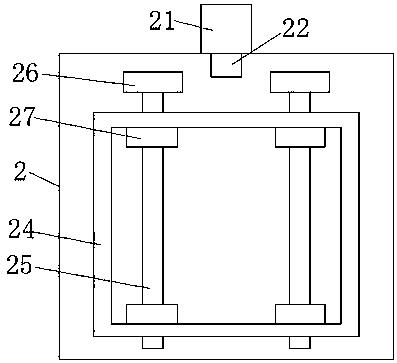

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a kind of multi-groove rolling spring cleaning machine provided by the present invention includes a frame, several cleaning tanks 2, several groups of hooks, a first cylinder 4, a first cylinder connecting rod 5, a fixed frame 6 and an electrical control system; The frame includes a bottom frame 11, several support frames 12 and a frame 13; several of the support frames 12 are installed on the bottom frame 11; the frame 13 is installed on the top of several of the support frames 12; The cleaning tank 2 is fixedly installed in the bottom frame 11; the bottom frame 11 is a cuboid without a cover; the frame 13 is surrounded by a chute 14, and the fixed frame 6 is installed in the chute 14 Inside; the first cylinder 4 is installed on the frame 13, and the first cylinder connecting rod 5 connects the first cylinder 4 and the fixed frame 6; several groups of the hooks are installed on the fixed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com