Multifunctional anti-loosening skid

An anti-loosening, multi-functional technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of scratching products, increasing production costs, and easy loosening of product transportation, so as to achieve the effect of preventing scratches and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

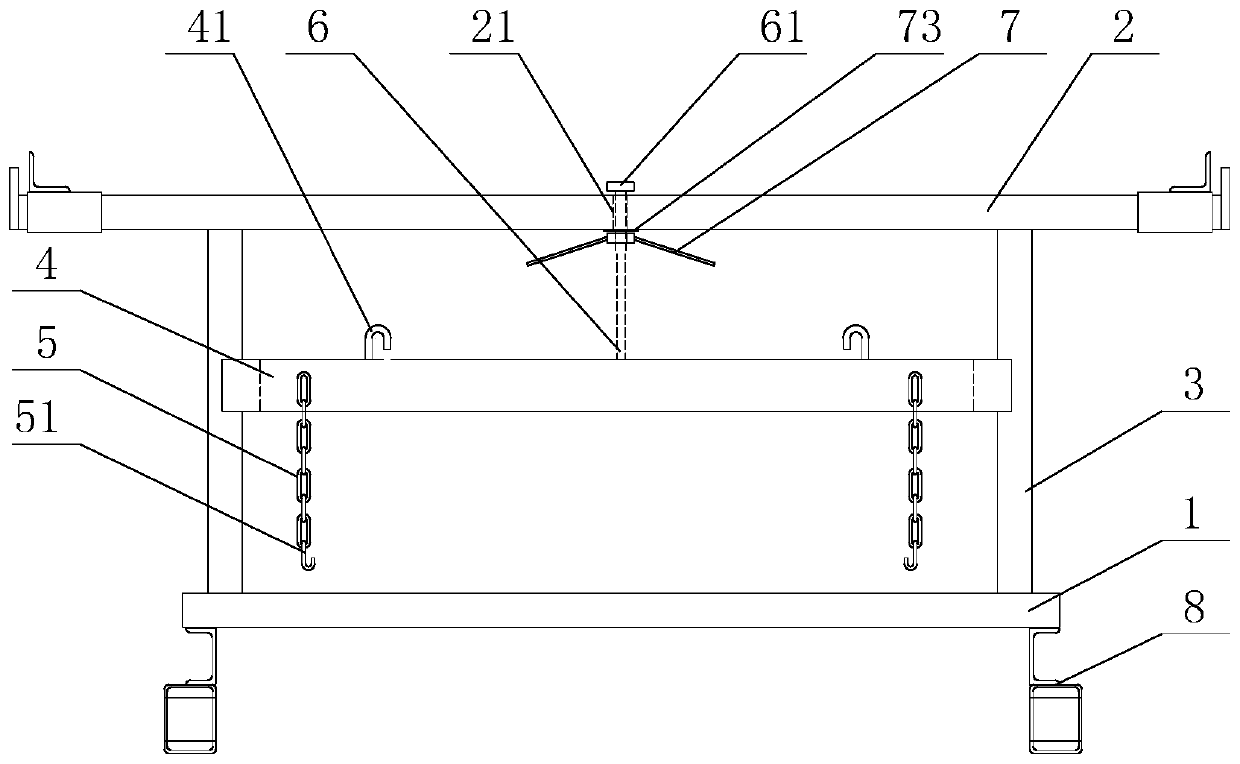

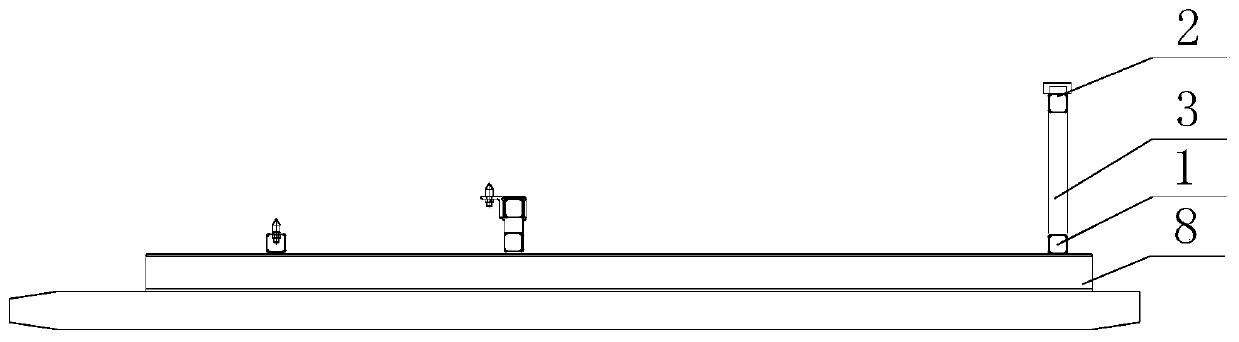

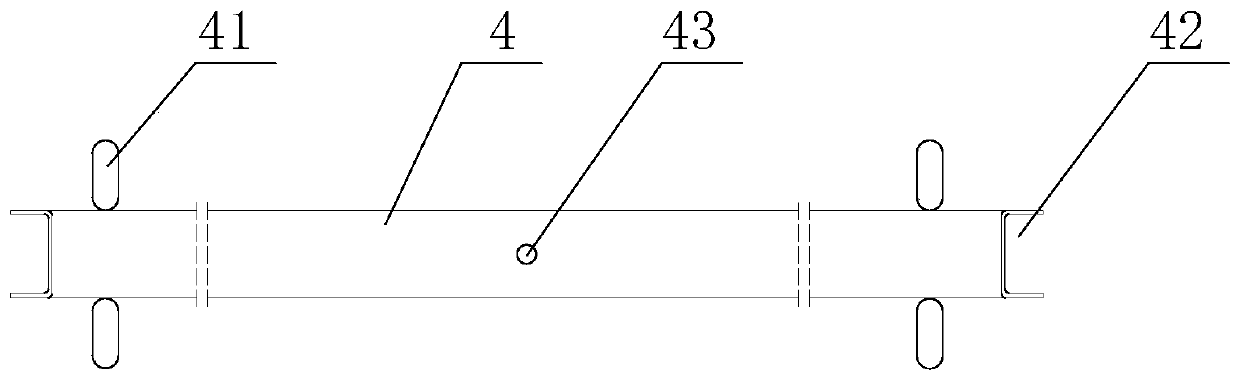

[0041] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a multifunctional anti-loosening skid, including a base 8, and one end of the base 8 is provided with a support frame, and the support frame includes a lower beam 2 connected to the base 8, and the two ends of the lower beam 2 They are respectively connected to the upper beam 1 used to support the product through the column 3; the support frame also includes a lifting rod 4, a screw rod 6 and a rotation adjustment mechanism 7; see image 3 and Figure 4 As shown, the lifting rod 4 is horizontally arranged between the upper beam 1 and the lower beam 2, and is connected with the upper beam 1 through a screw 6; at least one binding mechanism for fixing the product is provided on the lifting rod 4; in this embodiment, Binding mechanism is provided with two, is arranged on the two ends of elevating rod 4 respectively. The rotation adjustment mechanism 7 is installed on the screw rod 6, a...

Embodiment 2

[0050] see Figure 8As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the upper beam 1 is provided with a second connection hole, and the lifting rod 4 is provided with a second threaded through hole 44; the lower end of the screw rod 6 The upper end of the screw rod 6 is rotatably connected to the second connecting hole through the second threaded through hole 44 and threadedly engaged therewith. Specifically, a limit block 61 is provided at the lower end of the screw rod 6 . It is possible to prevent the screw 6 from coming out of the second threaded through hole 44 . One side of the nut 71 is a resisting surface for resisting the lifting rod 4 , and a gasket 73 is arranged between the resisting surface and the lifting rod 4 .

[0051] see Figure 9 and Figure 10 As shown, the working principle of Embodiment 2 of the present invention is:

[0052] 1. After placing the spreader for the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com