Cotton opening device for textile spinning

A technology of driving device and removing device, which is applied in the direction of cleaning with toothed tools, fiber cleaning machine, etc., can solve the problems of easy crushing of raw cotton, waste of raw cotton, and inconvenient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

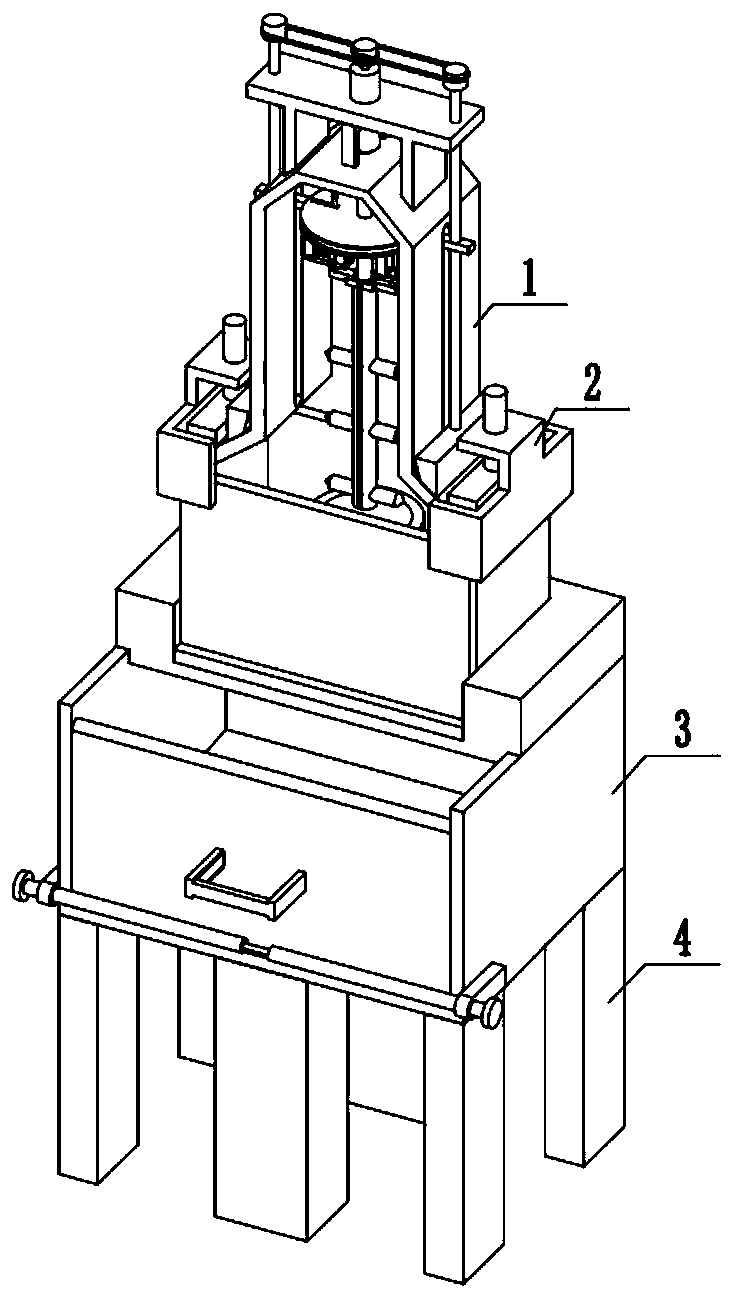

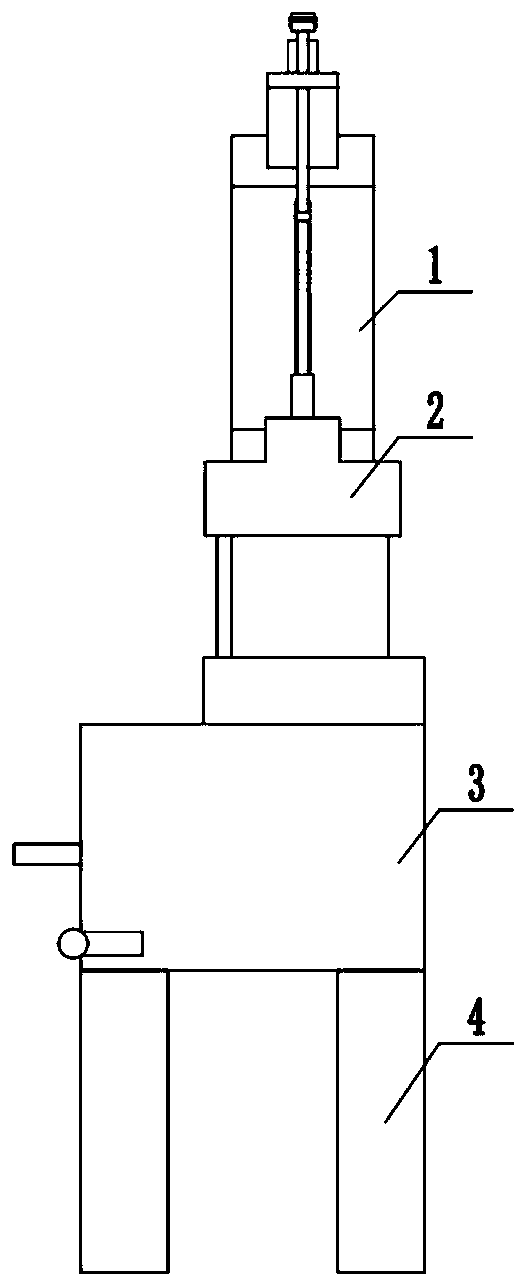

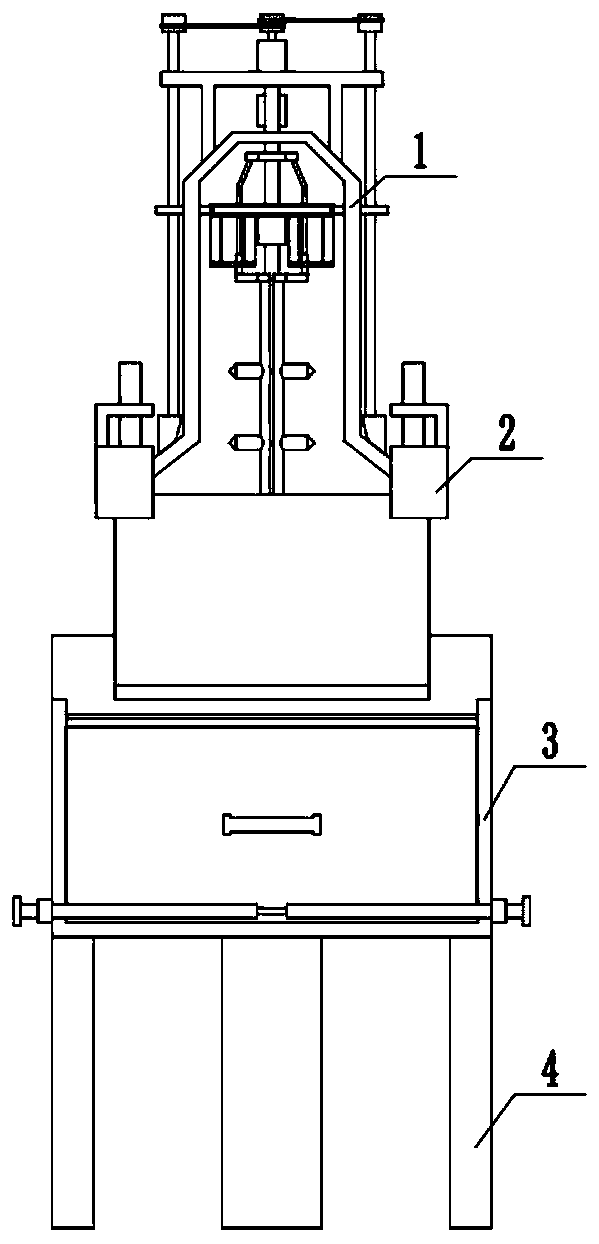

[0042] Combine below figure 1 , 2 , 3, 4 illustrate the present embodiment, a cotton opening device for textile spinning, including a cotton opening processing device 1, a cotton collecting device 2, a cotton taking device 3 and a support foot 4, and the cotton opening processing device 1 is fixed Installed on the cotton collection device 2, the cotton collection device 2 is fixedly installed on the cotton take-out device 3, and the cotton take-out device 3 is fixedly installed on the support foot 4, and the support foot 4 is provided with a plurality of.

specific Embodiment approach 2

[0044] Combine below Figure 5 , 6 , 7, 8, 9, 10, 11, 12, 13 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The described cotton opening processing device 1 includes a cotton opening driving device 1-1, an outer shell 1- 2. The cotton opening device body 1-3, the cotton opening device 1-1 is fixedly installed on the outer shell 1-2, the cotton opening device body 1-3 is installed on the outer shell 1-2, and the cotton opening device body 1-3 Installed on the cotton opening driving device 1-1;

[0045] The cotton opening driving device 1-1 includes a driving device fixing frame 1-1-1, a power motor A1-1-2, a transmission pulley A1-1-3, a transmission belt A1-1-4, and a transmission pulley B1-1- 5. Driving screw A1-1-6, driving belt B1-1-7, driving pulley C1-1-8, driving screw B1-1-9, device fixing block 1-1-10, driving device fixing frame 1-1- 1 is fixedly installed with a power motor A1-1-2, the output end of the power motor A1-1-2 is equ...

specific Embodiment approach 3

[0050] Combine below Figure 14 , 15 , 16 illustrates this embodiment, and this embodiment is further described to Embodiment 1, and described cotton collecting device 2 comprises screw rod fixing block 2-1, transmission screw rod D2-2, card frame 2-3, cotton collecting box 2-4 , Raw cotton placement box 2-5, movable baffle A2-6, fixed bottom frame 2-7, screw fixed block 2-1 is fixedly installed on the cotton collection box 2-4, and the transmission screw D2-2 is movably installed on the screw through the bearing On the fixed block 2-1, a card frame 2-3 is installed on the transmission screw rod D2-2, and there are two card frames 2-3, the card frame 2-3 and the cotton collection box 2-4 and the movable baffle A2-6 In contact with each other, the bottom of the cotton collection box 2-4 is provided with a groove, the movable baffle A2-6 is installed in the groove, the raw cotton storage box 2-5 is installed in the cotton collection box 2-4, and the cotton collection box 2-4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com