Bottle cap assembly

A technology of bottle caps and components, applied in the field of medical inspection, can solve problems such as instability, complex claw structure, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

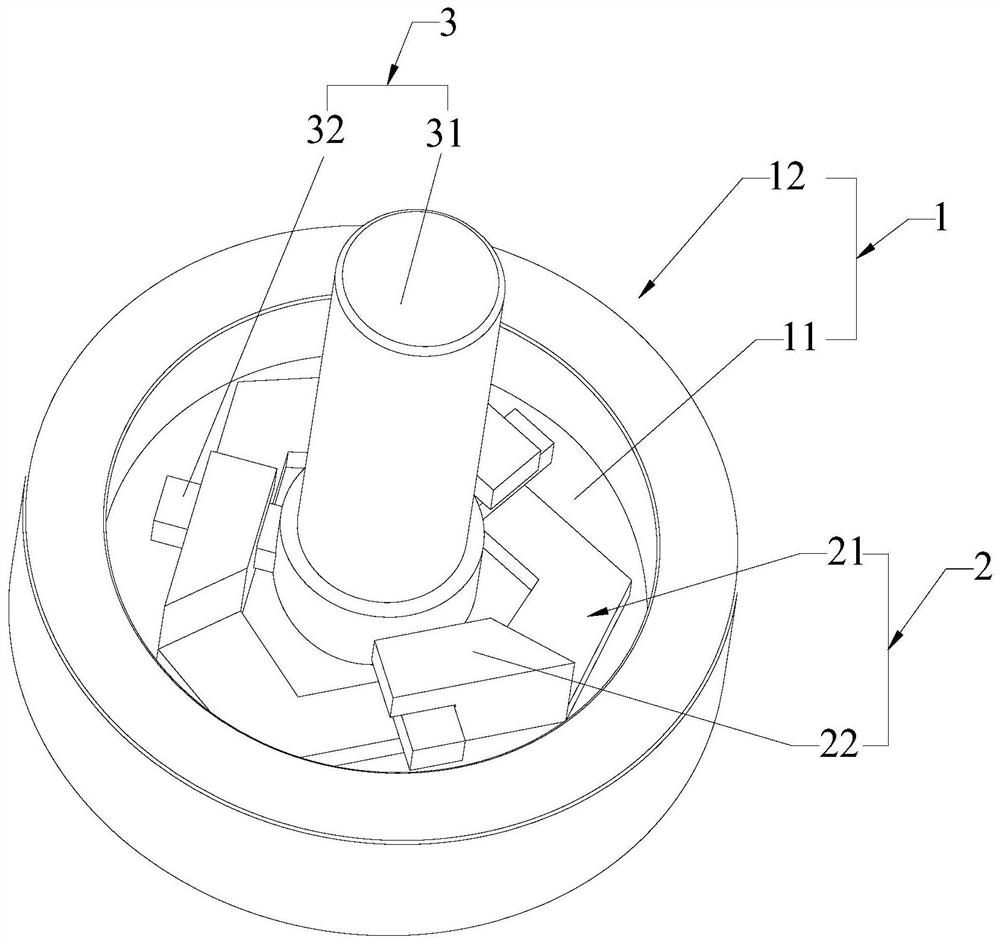

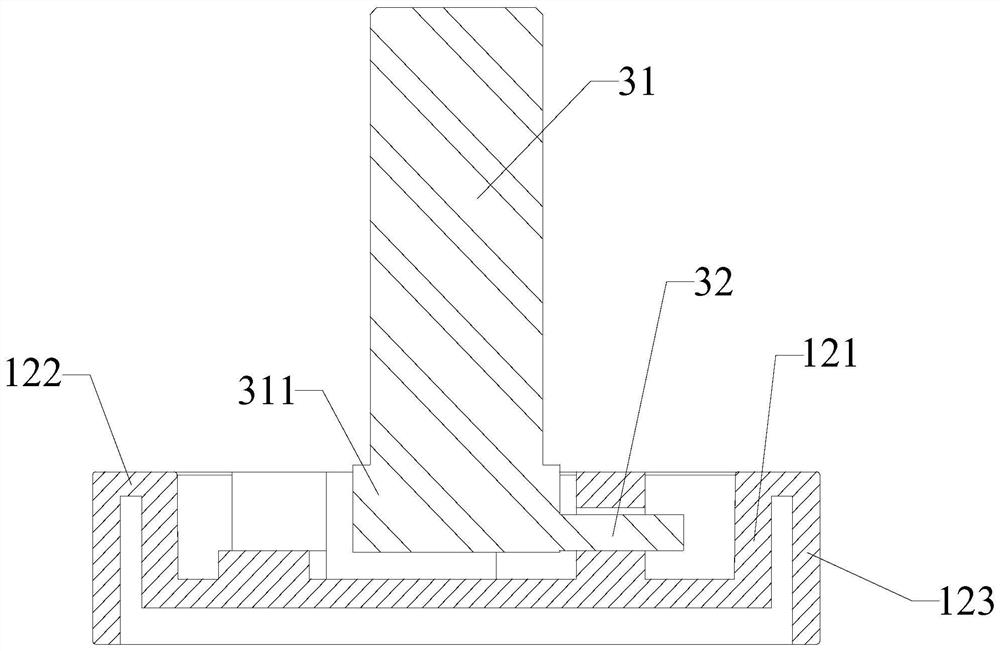

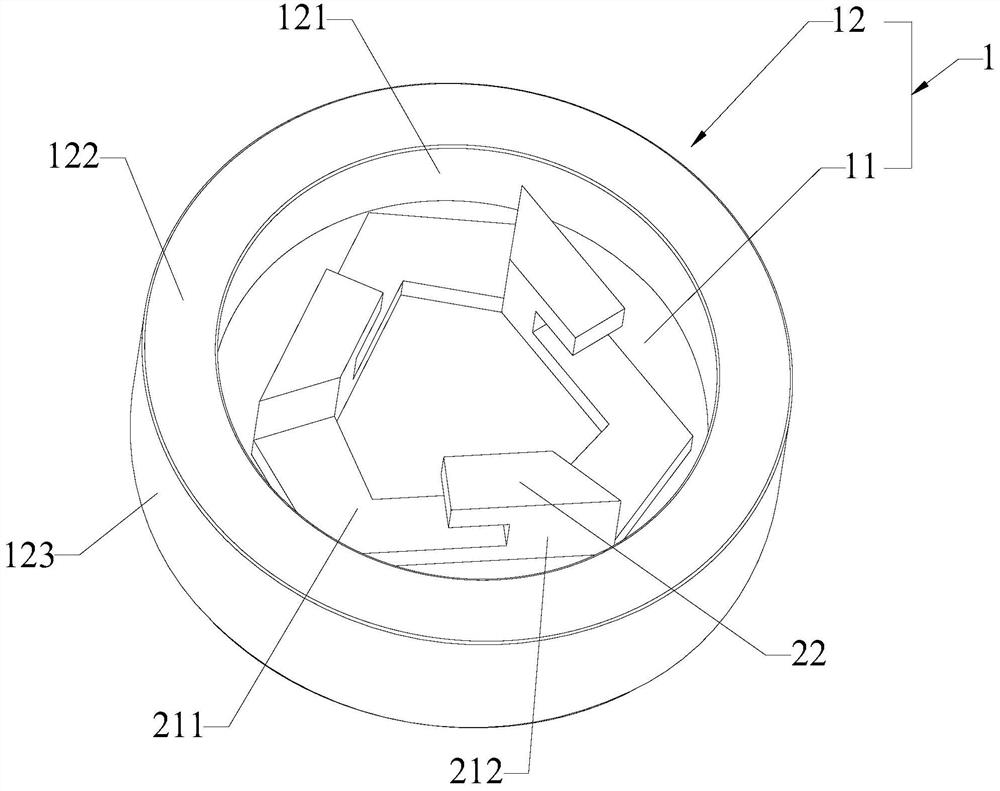

[0041] Please refer to Figure 1 to Figure 3 As shown, a bottle cap assembly includes a bottle cap 1, a push assembly 2 and a screw head 3, the bottle cap 1 includes a base 11 and a threaded portion 12, and the threaded portion 12 is circumferentially arranged on the edge of the base 11, so The threaded part 12 is used for threading the bottle cap 1 on the reagent bottle; the push assembly 2 includes a transmission frame 21 and a hanging plate 22, and the transmission frame 21 is arranged on the top surface of the base 11 around the center line of rotation of the bottle cap 1 Above, the transmission frame 21 encloses an area for placing the rotary head 3 to rotate, and the hanging plate 22 is provided on the top of the transmission frame 21, and the hanging plate 22 is used for the bottle cap 1 to be suspended on the rotary head 3; The rotary head 3 rotates in the area to drive the rotation of the bottle cap 1 .

[0042] The transmission frame 21 includes a guide plate 211 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com