Circular weaving machine

A circular loom, frame technology, applied to the circular loom. domain, able to solve problems such as troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

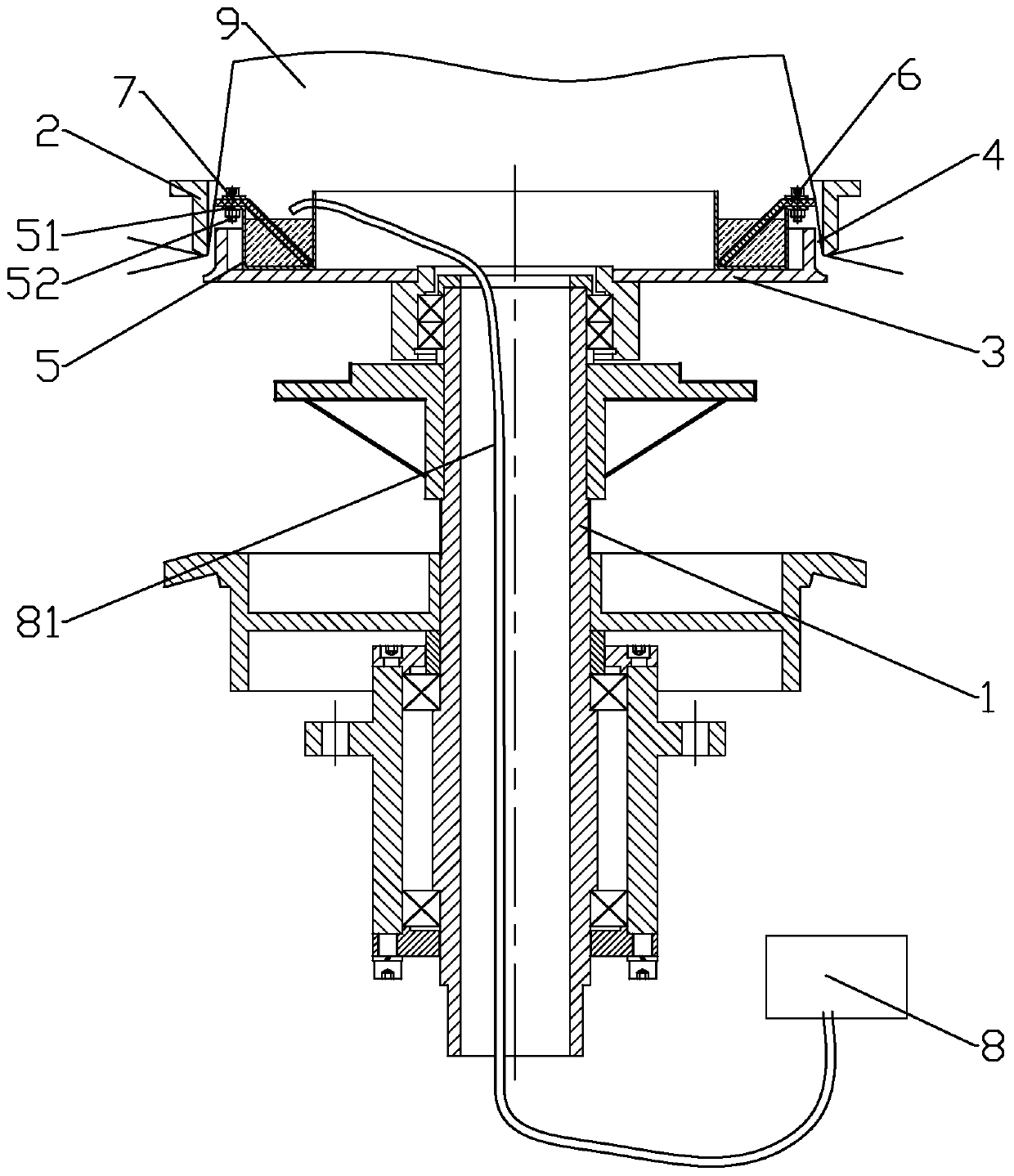

[0017] The present invention provides a kind of circular loom, comprises main frame, and main frame comprises frame and main shaft 1, and main shaft 1 is installed on the frame, as figure 1 As shown, the frame is provided with an outer size ring 2, and the top of the main shaft 1 is provided with an inner size ring 3, between the outer size ring 2 and the inner size ring 3, an annular passage 4 for the woven bag 9 to pass through is formed, and the inner size ring 3 An oil tank 5 is arranged on the oil tank 5, and a felt 6 is arranged on the oil tank 5, and the felt 6 is immersed in the oil tank 5 and extends out of the oil tank 5 for contacting the woven bag 9.

[0018] The present invention utilizes the feature that the inner size ring 3 is located inside the woven bag 9 without affecting the normal weaving of the woven bag 9, and applies a lubricant to the inside of the woven bag 9 during the weaving and forming process of the woven bag 9, and utilizes the felt 6 As long as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap