High-precision weighing device for test box

A weighing device, high-precision technology, applied in the direction of measuring device, material absorption weighing, detailed information of weighing equipment, etc., can solve the problem of poor safety, easy deformation of soft sealing sleeve, accessory cabin and weighing cabin The problem of pinching the user's arm and other problems can be achieved to achieve the effect of stable placement and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

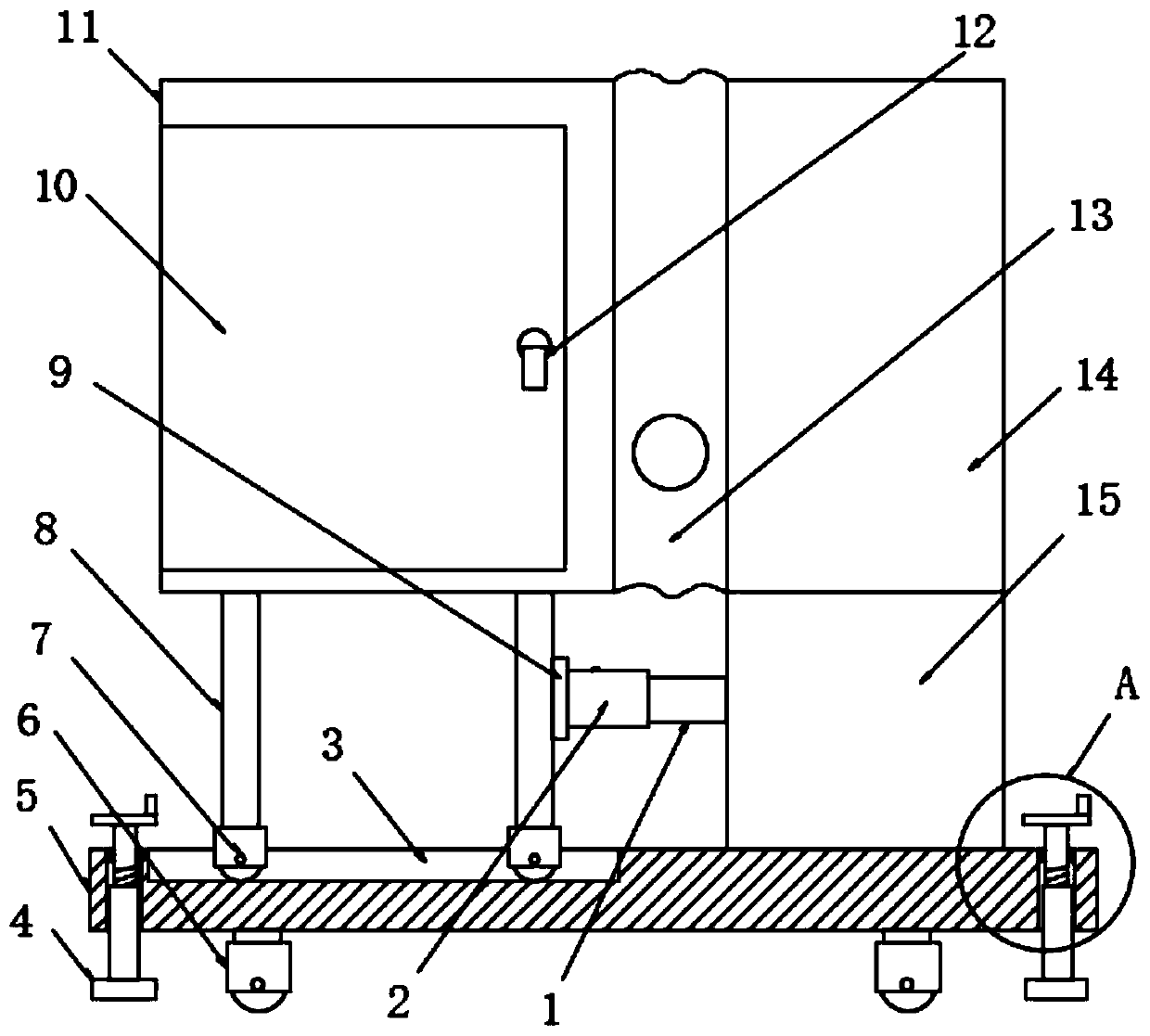

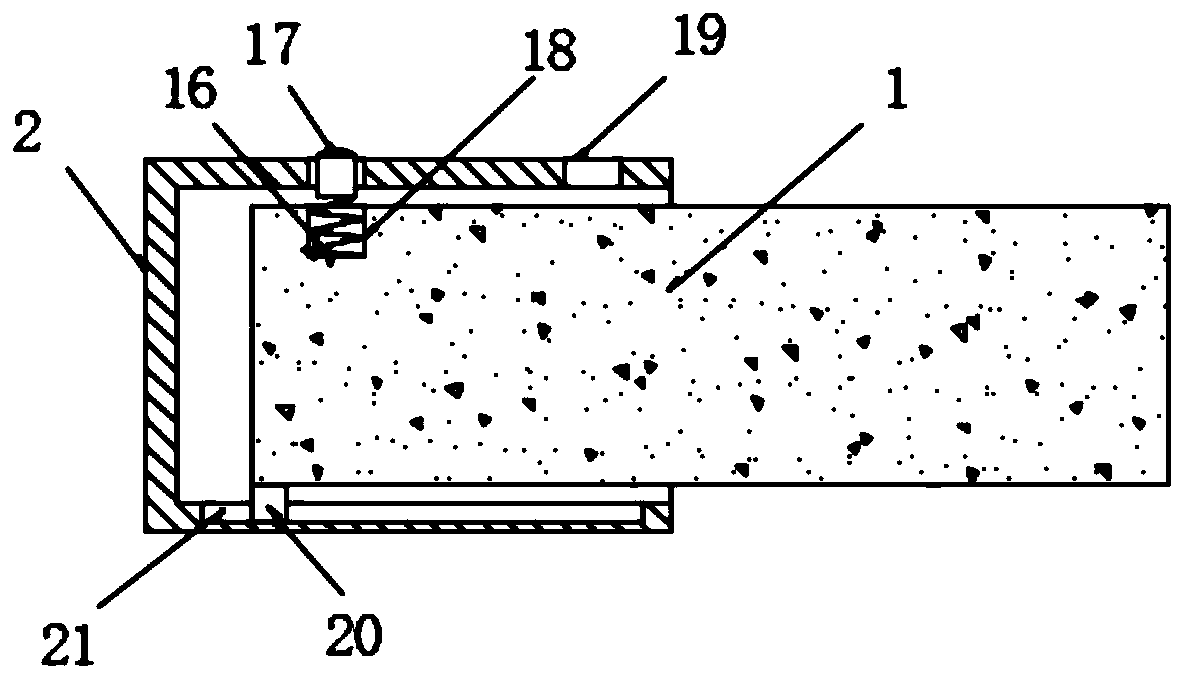

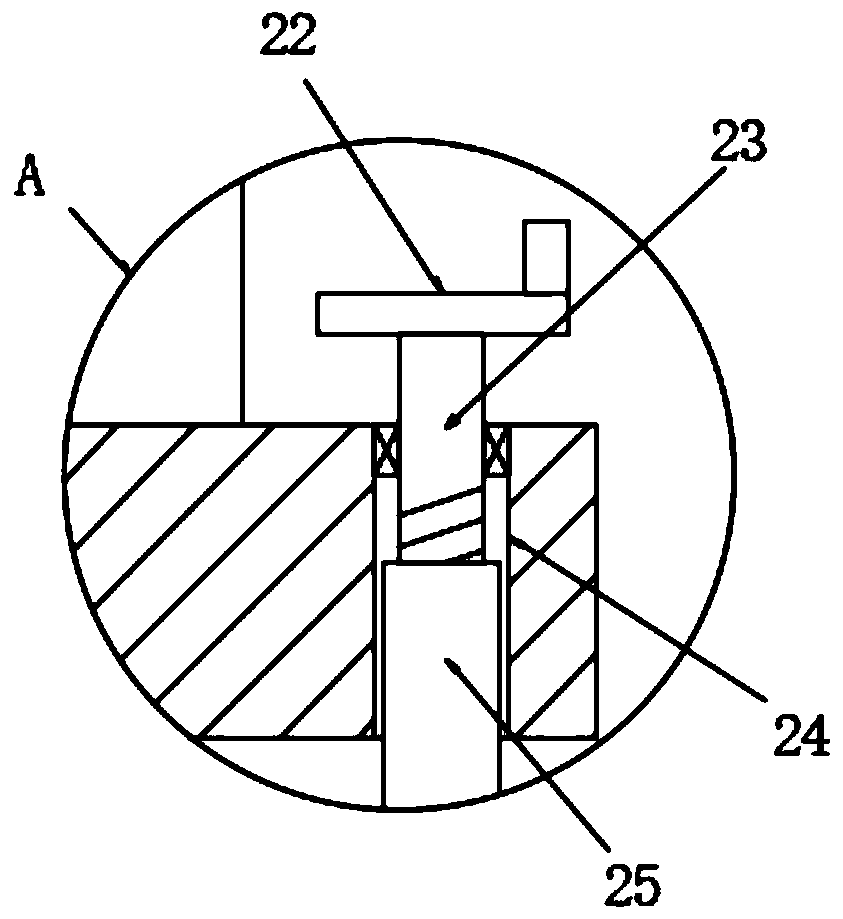

[0021] see Figure 1-3 , a high-precision weighing device used in a test chamber, including a bottom plate 5, a shock-absorbing seat 15 and two guide rails 3 are respectively arranged in the middle of the upper surface of the bottom plate 5, and a scale is fixedly installed on the upper surface of the shock-absorbing seat 15 The heavy cabin 14, one side of the weighing cabin 14 is fixedly connected with a soft sealing sleeve 13, one side of the soft sealing sleeve 13 is fixedly connected with an accessory cabin 11, and the lower surface of the accessory cabin 11 is evenly fixed with four legs 8 , the lower surface of each leg 8 is fixedly equipped with a guide pulley 7 matching the guide rail 3, and the outer sides of the two legs 8 on the right are fixedly installed with a connecting plate 9, and one side of the connecting plate 9 is fixed The connection housing 2 is installed, and the outer side of the connection housing 2 is provided with two limit holes 19, and the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com