Microphone packaging structure and forming method thereof

A packaging structure and microphone technology, applied in the field of MEMS, can solve the problems of affecting the acoustic performance, increasing the proportion of product failures, reducing the volume of the cavity, etc., to achieve the effect of increasing the contact area and improving the bonding reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of a microphone package structure and its forming method provided by the present invention will be described in detail below with reference to the accompanying drawings.

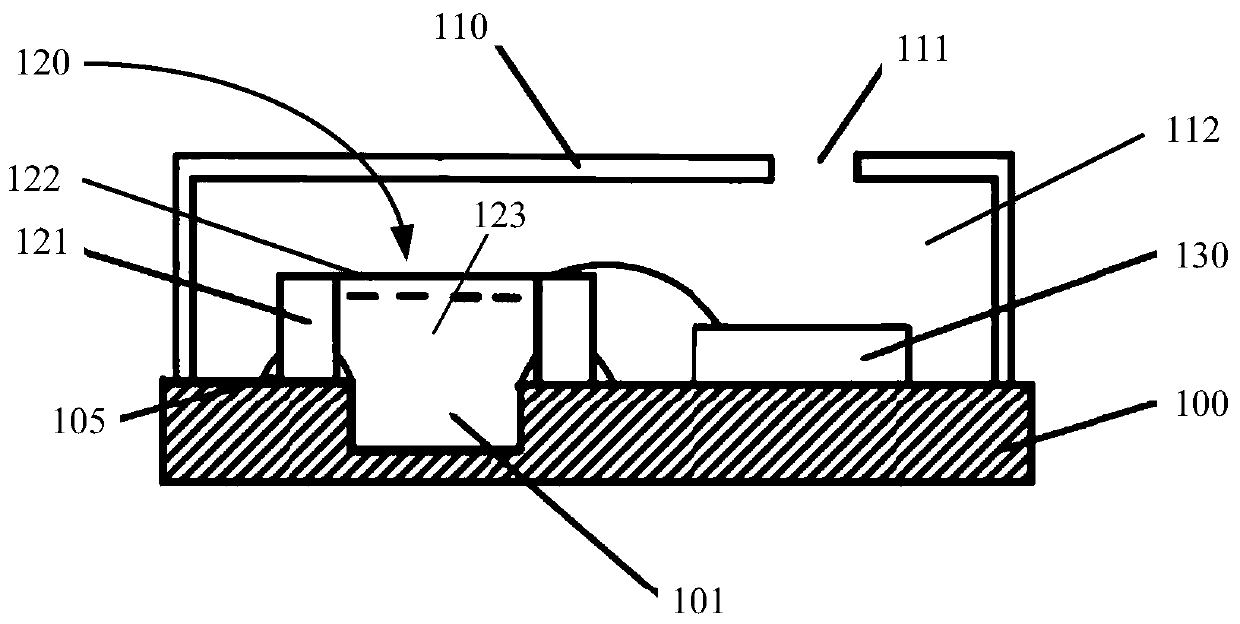

[0036] Please refer to figure 1 , is a structural schematic diagram of a microphone package structure according to a specific embodiment of the present invention.

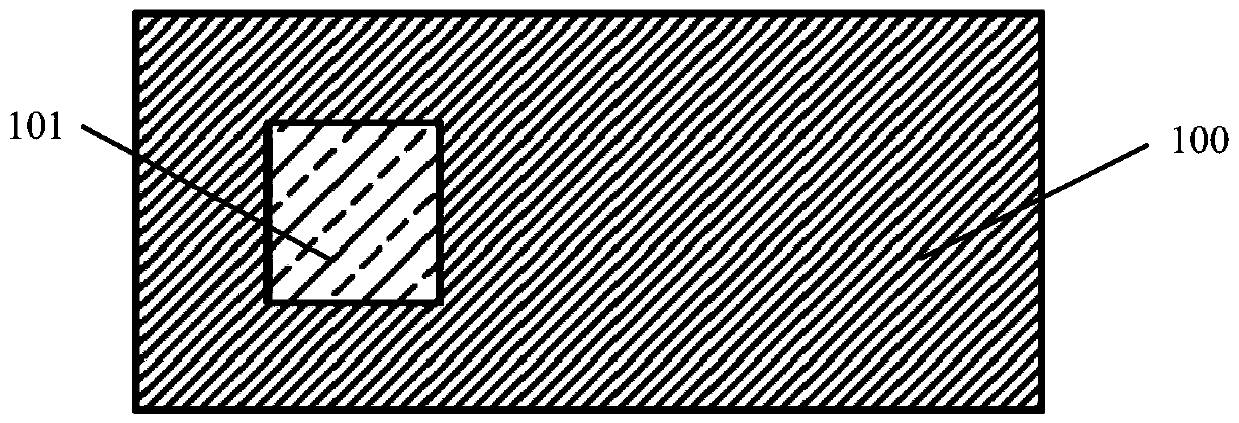

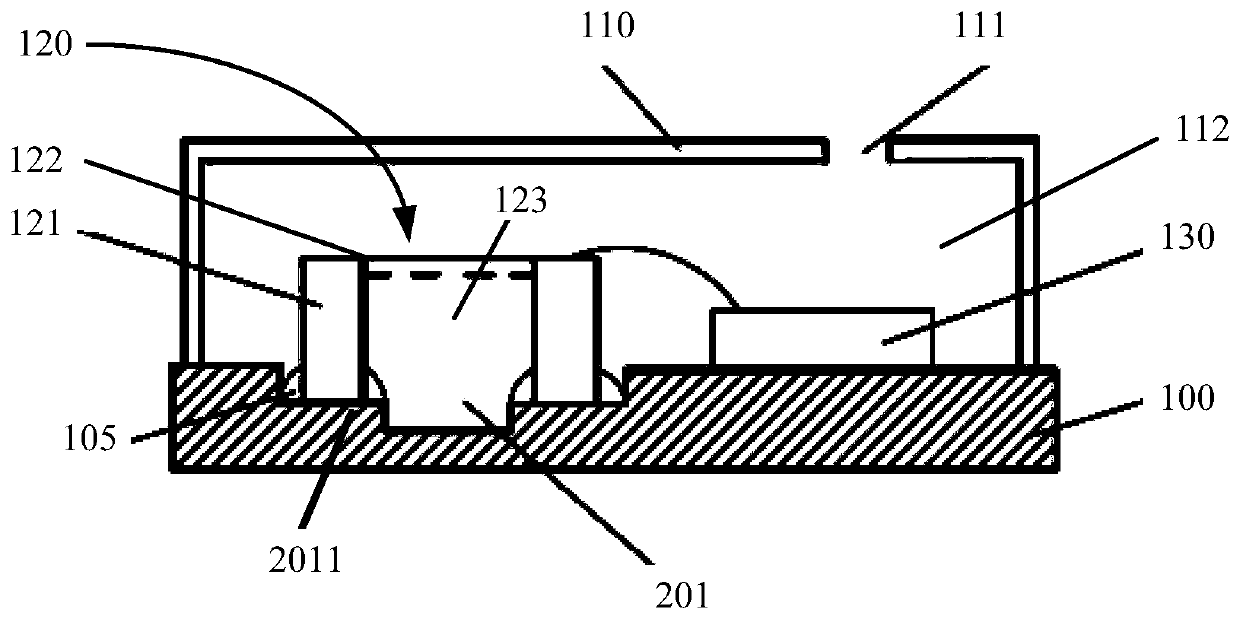

[0037] The microphone packaging structure includes: a substrate 100, a first recess 101 is formed on the surface of the substrate 100; The first cavity 112, the first recess 101 is located in the first cavity 112; the microphone chip 120 is arranged in the first cavity 112, the microphone chip 120 includes a pressure sensing layer 122 and a support structure 121, a second cavity 123 is formed between the support structure 121 and the pressure-sensing layer 122, the top of the support structure 121 supports the pressure-sensing layer 122, and the bottom is fixed on the surface of the substrate 100, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com