PCB golden finger tape attaching equipment and tape attaching method

A PCB board, gold finger technology, applied in the PCB board gold finger sticking equipment and the field of sticking, can solve the problems of low sticking efficiency, high sticking cost, wrinkles, etc., and achieve high sticking accuracy and high sticking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

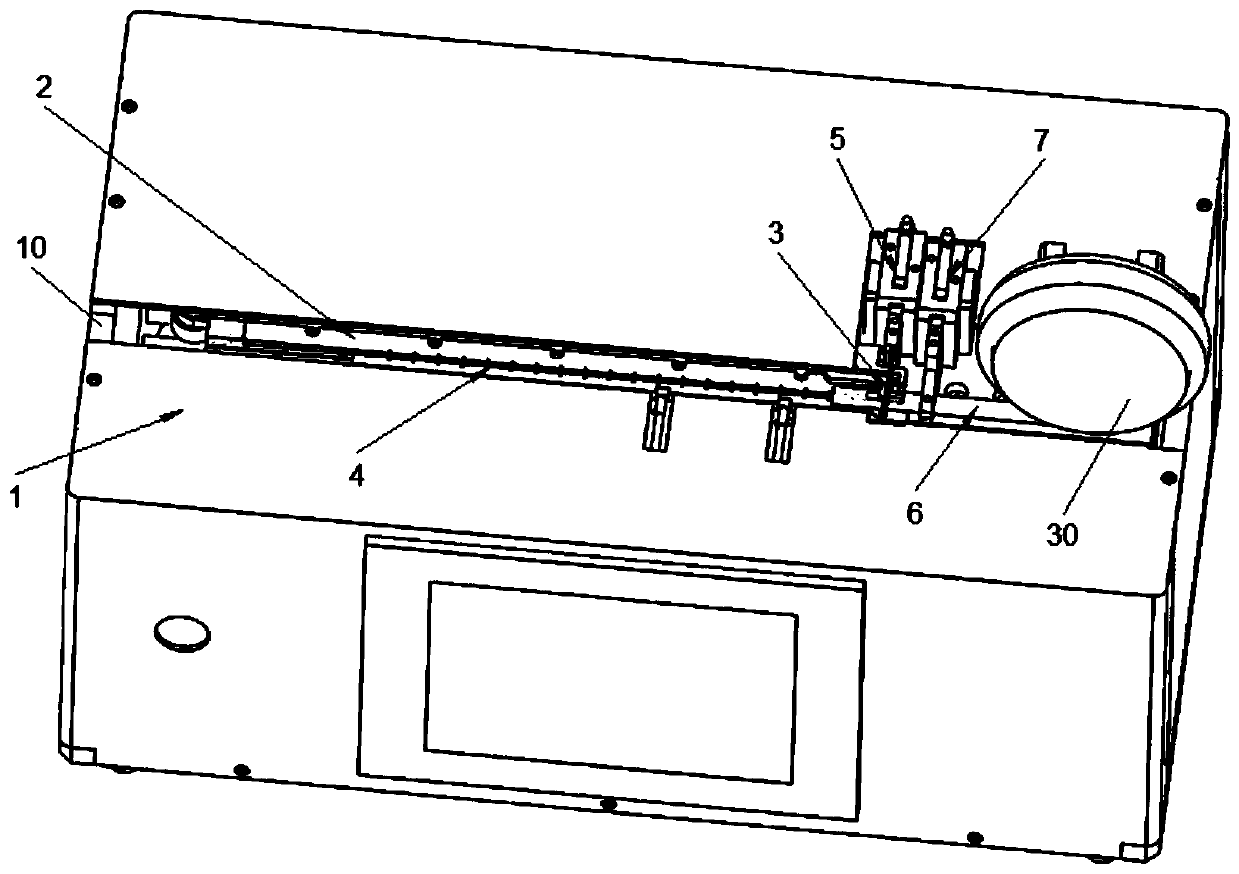

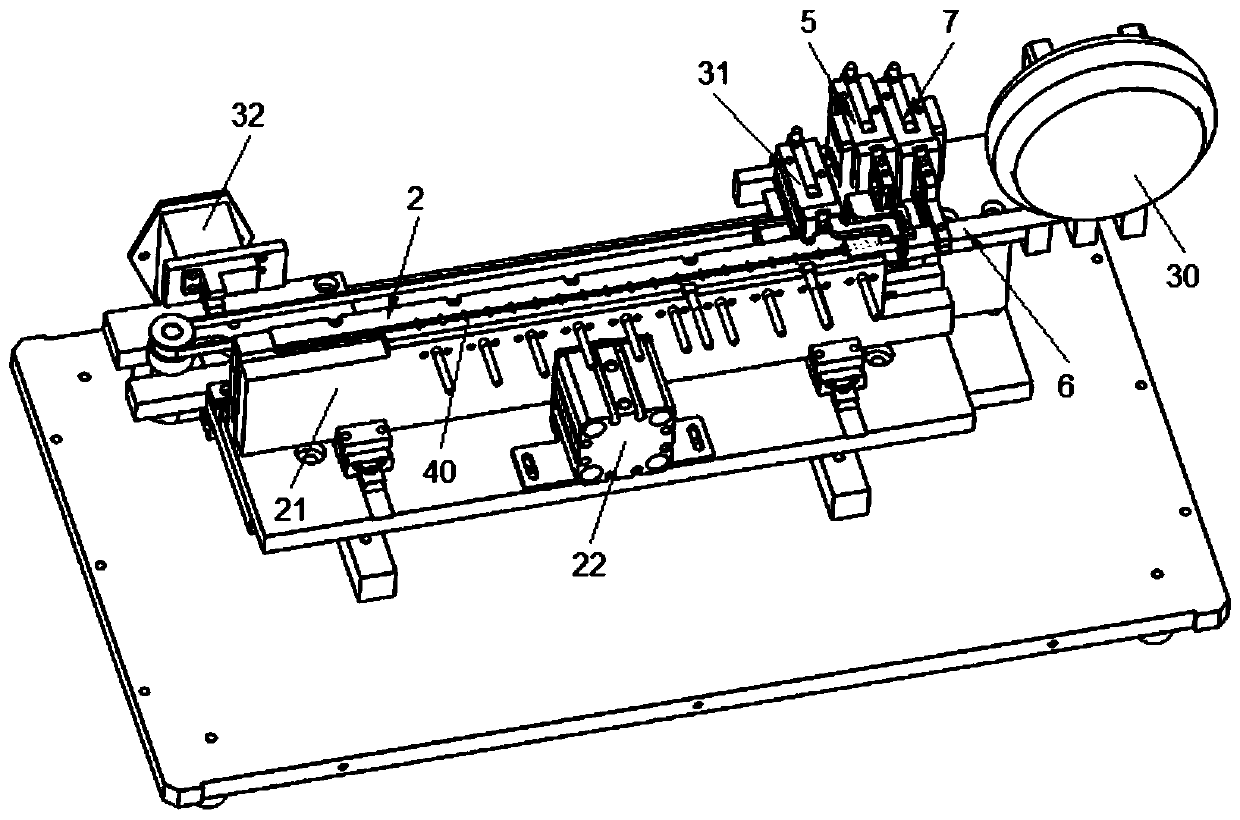

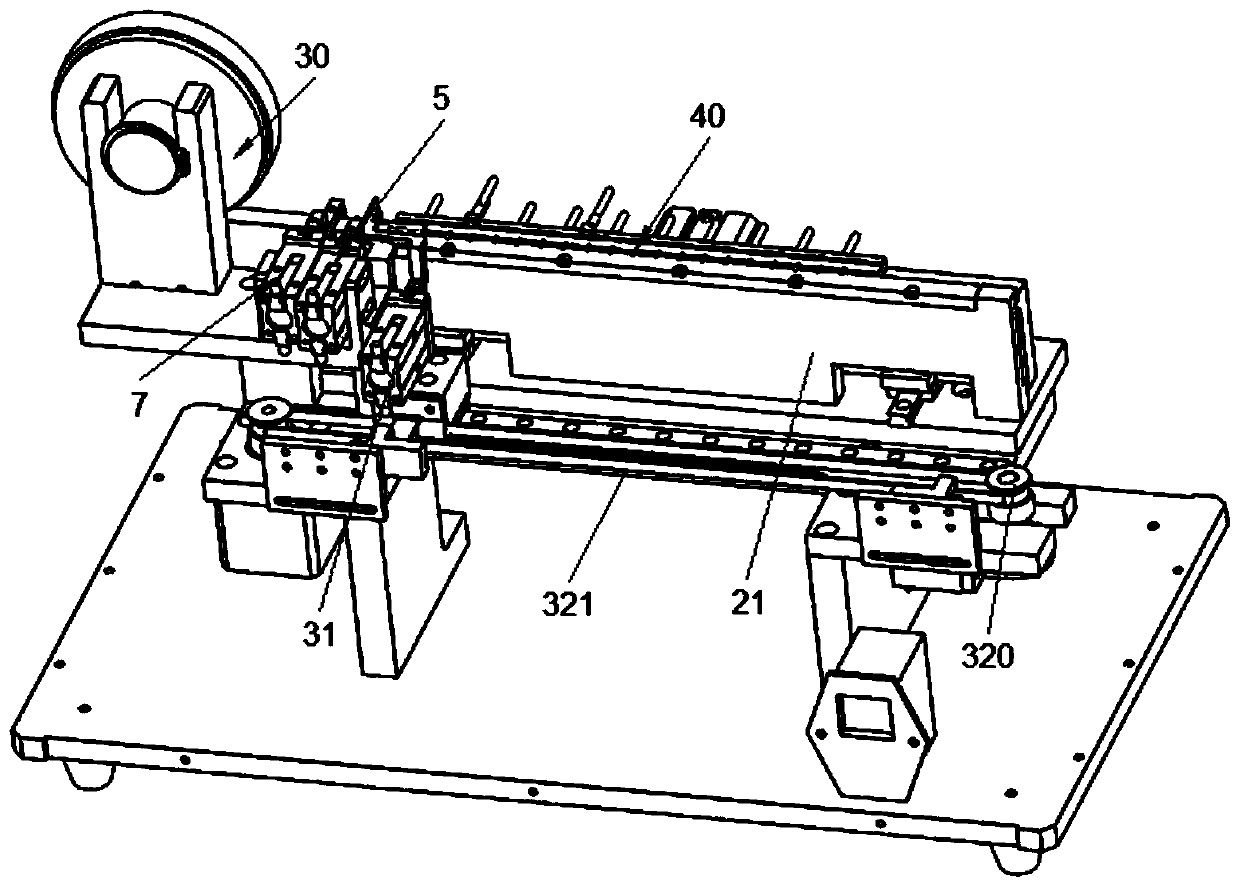

[0039] see figure 1 As shown, Embodiment 1 of the present invention provides a PCB gold finger glue sticking equipment, which includes a workbench 1, a clamping device 2, a glue feeding device 3, a negative pressure structure 4 and a glue cutting device 5, and on the workbench 1 There is a slot 10 extending straight, and the clamping device 2 is located at the slot 10. The height of the clamping device 2 is not higher than the height of the workbench 1. The clamping device 2 has two relatively movable clamping surfaces 20, The two clamping surfaces 20 are far away from each other to form a clamping space for clamping PCB boards, and the distance between the two clamping surfaces 20 can be adjusted according to PCB boards of different thicknesses to clamp PCB boards of different thicknesses The glue feeding device 3 includes a material roll 30 for winding the adhesive tape 6, a clamping assembly 31 and a first driving device 32, and the clamping assembly 31 is used to clamp the...

Embodiment 2

[0048] see Image 6 As shown, the basic content of embodiment 2 of the present invention is the same as that of embodiment 1, except that the glue assembly 31, the glue assembly 31 of embodiment 2 of the present invention includes two glue heads 310 arranged up and down, the glue head 310 is arranged along the length direction of the clamping plate 21, and the clamping head 310 is provided with a U-shaped card slot 311 for clamping the PCB board, and the length of the adhesive tape 6 clamped by the clamping head 310 is just in line with the The depths of the notches are equal, and the clamping space formed between the U-shaped card slot 311 and the two clamping plates 21 is connected. When applying glue, insert the PCB board from the U-shaped card slot 311 into the clamping space. In this way, the adhesive tape 6 clamped by the clamping head 310 is just attached to the edge of the PCB board, so that the waste of the adhesive tape 6 will not be caused, and the length of the adh...

Embodiment 3

[0050] Embodiment 3 of the present invention provides a method for applying glue to a PCB gold finger, which uses the above-mentioned equipment for applying glue to a PCB gold finger to apply glue to a PCB gold finger. The specific steps are as follows:

[0051] At first the first driving device 32 drives the clamp assembly 31 to move towards the direction close to the material roll 30, so that the clamp assembly 31 is pulled out through the glue cutting device 5 and clamps the adhesive tape 6 sent by the material roll 30; then the first drive The device 32 drives the clamping assembly 31 to move away from the material roll 30, and the adhesive tape 6 is adsorbed on the clamping device 2 under the action of the negative pressure generated by the negative pressure structure 4, and is determined according to the length of the PCB board to be pasted. The length of the tape 6 is to control the movement distance of the material roll 30, so as to meet the glue length of PCB boards o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com