Multi-channel activated carbon adsorption device

An activated carbon adsorption and multi-channel technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of fast adsorption attenuation effect, workload cost, and increased maintenance, and achieve consistent adsorption attenuation effect and reduce maintenance. The effect of reasonable cost and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

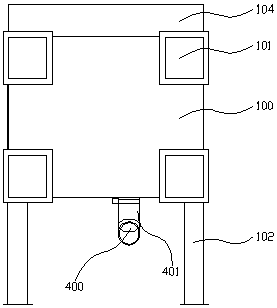

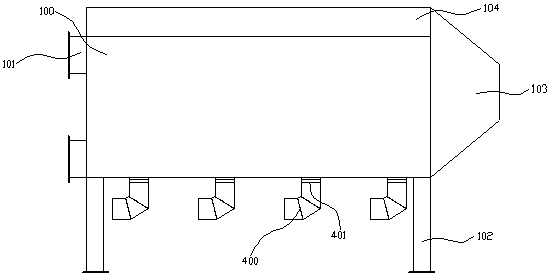

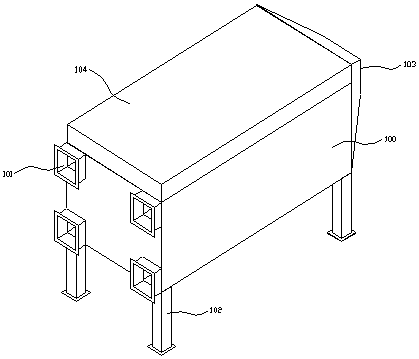

[0029] according to Figure 1 to Figure 6 As shown: this embodiment provides a multi-channel activated carbon adsorption device, including an activated carbon box 100 and four groups of activated carbon plates 300 inside it, wherein:

[0030] The activated carbon box 100 is a cuboid box body as a whole, and four separate adsorption chambers 500 are arranged respectively from the left side to the right side inside the activated carbon box 100. The adsorption chambers 500 are separated by partitions, and the partitions are arranged vertically and their The edge is connected and airtight with the inner wall of the activated carbon box 100, and the middle part of the adsorption chamber 500 is provided with an activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com