A kind of wood interlayer thermoplastic composite material and preparation method thereof

A composite material and thermoplastic technology, which is applied in the direction of wood layered products, wood processing equipment, wooden veneer joints, etc., can solve the problem of environmental protection not in line with the development trend of the times, poor waterproof and mothproof performance of the wooden floor of the truck, To solve the problems of low performance of wooden building formwork, achieve the effect of high cost performance, good nail holding force, excellent strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

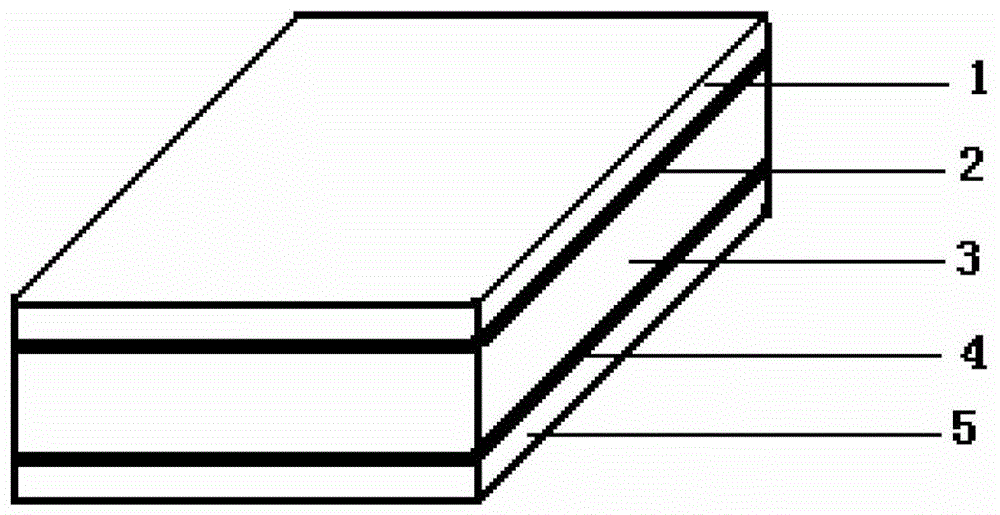

[0023] The panel material is made of continuous fiber-reinforced polypropylene-based composite material. The core material is wood plywood with a thickness of 18mm. The weight percentage of glass fiber in the panel material is about 50%, and the panel thickness is 2mm.

[0024] The preparation of the upper and lower panels of glass fiber reinforced thermoplastic composite materials: the glass fiber reinforced polypropylene base prepreg tape is laminated according to the mechanical property requirements of the specific application according to 0° / 90° / 0°, and the ratio of 2:1 meets the requirement of The mechanical strength of the building formwork length is higher than that of the width direction, so that the material has a higher utilization rate. Then composite molding is carried out under certain hot-pressing and cold-pressing process conditions, wherein the hot-pressing temperature is 180°C, the hot-pressing pressure is about 3MPa, the hot-pressing time is 10min, the cold-pr...

Embodiment 2

[0027] The panel material is made of continuous fiber-reinforced polypropylene-based composite material, and the core material is wood plywood with a thickness of 25mm. The weight percentage of glass fiber in the panel material is about 55%, and the panel thickness is 3mm.

[0028] The preparation of the upper and lower panels of glass fiber reinforced thermoplastic composite materials: the glass fiber reinforced polypropylene based prepreg tape is laid according to the mechanical performance requirements of the specific application according to 0° / 90° / 0°, and the ratio of 2:1 is in line with It solves the application situation that the mechanical strength in the length direction is higher than that in the width direction, so that the material has a higher utilization rate. Then composite molding is carried out under certain hot-pressing and cold-pressing process conditions, wherein the hot-pressing temperature is 180°C, the hot-pressing pressure is about 3MPa, the hot-pressing...

Embodiment 3

[0033] A kind of preparation method of wooden sandwich thermoplastic composite material, it is characterized in that, the method comprises the following steps:

[0034] (1) Spread the continuous glass fiber evenly, pass through the traction unit and preheat it, then fully impregnate the composite unit with polypropylene molten resin, and then pass through the action of the flattening unit and the winding unit to obtain the continuous glass fiber unidirectional prepreg The weight percentage range of the glass fiber in the prepreg tape is 40%, and the used fiber fineness range is 150Tex.

[0035] (2) Preparation of the upper panel and the lower panel: the glass fiber reinforced polypropylene-based prepreg tape is laminated at 0° / 90° / 0°, hot-pressed and then cold-pressed under the pressure roller and roller pressing device , wherein the hot-pressing temperature is 190°C, the hot-pressing pressure is 2.5MPa, the hot-pressing time is 15min, the cold-pressing pressure is gradually i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com