A small particle no-tillage and film precision seeder

A technology of small particles and seeders, applied to parts of seeders, sowing, planting methods, etc., can solve the problems of single structure, not maximizing the use value of machinery, single type of sowing, etc., and achieve the effect of maximizing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

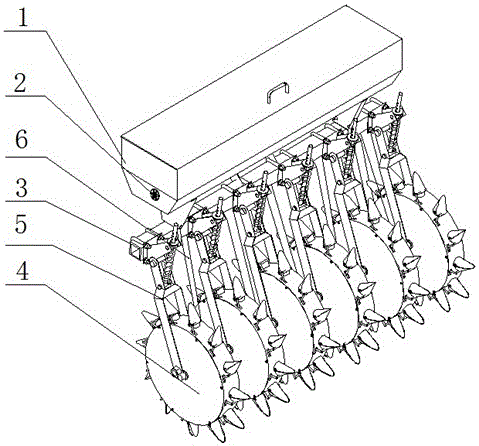

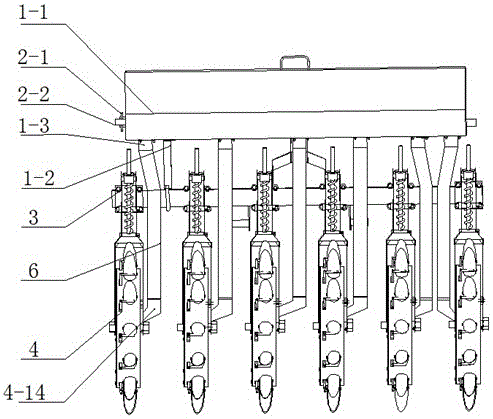

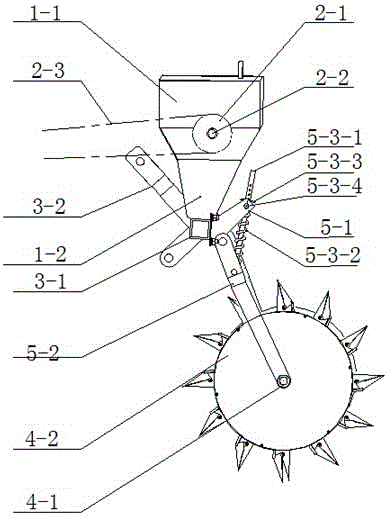

[0025] Below in conjunction with the accompanying drawings, the present invention will be further described in detail from the whole to the part:

[0026] like figure 1 , figure 2 , image 3 As shown, a small particle type membrane precision seeder includes a frame 3, and the frame 3 includes a beam 3-1 and a three-point suspension device 3-2, which are connected by welding. A fixing device 5 of the roulette-type duckbill punching mechanism 4 is installed on the rear lower end of the beam 3-1. The fixing device 5 includes a fixing plate 5-1, an H-shaped fixing rod 5-2 and a preloading device 5-3. The fixing plate 5-1 and the beam 3-1 are positioned and connected by two U-shaped double-headed screws 3-3, and the upper end of the fixing plate 5-1 is installed with a preloading device 5-3 through a pin 5-3-4, and an H-shaped fixing rod One end of 5-2 is movably connected to the lower end of the fixing plate 5-1, and the other end of the H-shaped fixing rod 5-2 is movably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com