Recyclable warp and weft flat filament reinforced polyolefin metallized composite film and preparation method thereof

A metallized film and polyolefin technology, applied in the field of flexible packaging, can solve the problems of high production cost, product defects, and difficult production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

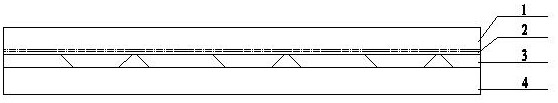

[0036] refer to figure 1 , the present embodiment provides a recyclable warp and weft flat wire reinforced polyolefin metallized composite film, which successively includes a woven flat wire layer, a polyolefin resin layer and a polyolefin metallized film layer; The silk is woven into a flat shape, and one side is treated with corona. The warp density and weft density of the woven flat yarn layer are 33 pieces / 10 cm, and the density of the woven flat yarn layer is 70-75g / m 2 ; The polyolefin resin layer is coated on the corona surface of the braided flat yarn layer, and compounded with the metal surface of the polyolefin metallized film layer.

[0037] Specifically, the warp and weft are melted and extruded from the raw material by two screw extruders, then cast and cooled from the die head through three channels, and then cut into strips and then stretched into flat yarns with a width of 3mm. , thickness is 0.04mm; Described warp thread, weft thread are three-layer composite...

Embodiment 2

[0053] Present embodiment is substantially the same as embodiment 1 technological process, and difference is:

[0054] The raw material composition of the polyolefin resin layer coated in step S3 is: 40% polyolefin resin C, 60% polyolefin resin D, wherein the grade of resin C is RB707CF, and the grade of resin D is 1018CA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com