Hydrocyclone accumulated-material flushing device

A technology for hydrocyclones and flushing devices, which is applied in the direction of swirl devices, devices in which the axial direction of the swirl can be reversed, grain processing, etc. High temperature and other problems, to achieve the effect of improving the flushing effect, reducing the cleaning workload, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

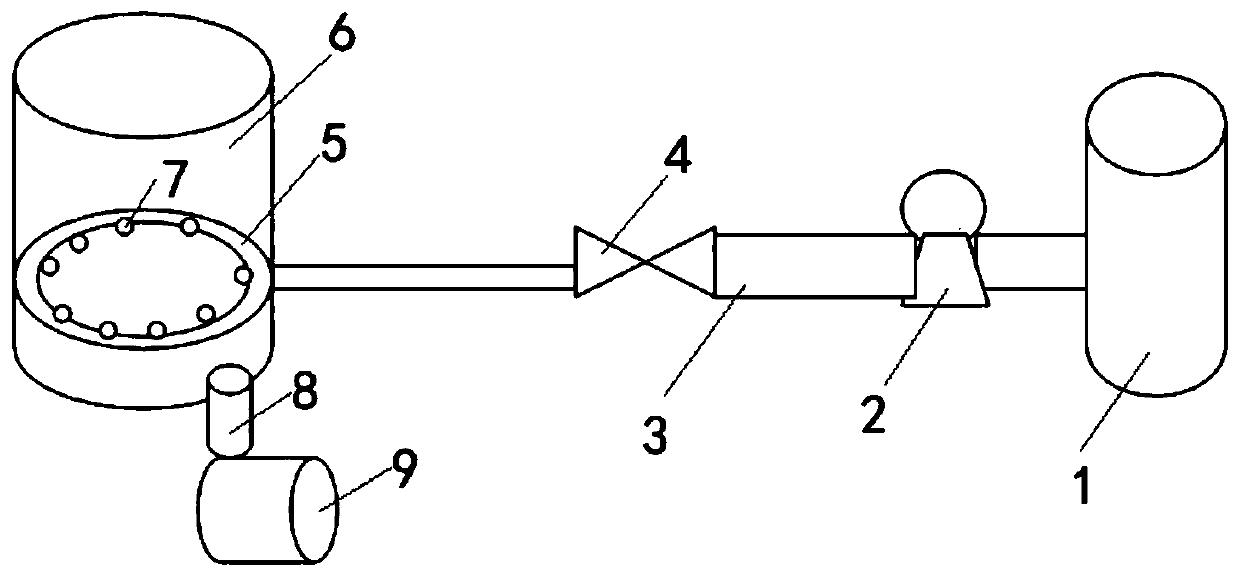

[0030] Attached below figure 1 The flushing device disclosed in this embodiment is further described;

[0031] Refer to attached figure 1 As shown, the hydrocyclone accumulation flushing device includes an annular pipeline 5 arranged inside the hydrocyclone 6, and a plurality of nozzles 7 are arranged at the bottom of the annular pipeline 5. In this embodiment, 8 nozzles are set, and 8 nozzles 7 are evenly spaced along the circular pipeline 5 ring direction.

[0032] The nozzle 7 is arranged obliquely, and the nozzle 7 is arranged obliquely downward from the inner side of the annular pipeline 5 to the outer side, and the water outlet of the nozzle 7 is opposite to the bottom wall of the hydrocyclone 6, so that an inclined angle is formed between the nozzle 7 and the inner wall of the hydrocyclone 6 , can improve the effect of hydrocyclone flushing.

[0033] The annular pipeline 5 is provided with a night inlet to communicate with the pipeline 3 , the pipeline 3 is communica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap