Multifunctional sand and gravel vibrating screen with screen mesh convenient to replace

A vibrating screen, multi-functional technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of affecting production efficiency, long cycle, unable to control the ratio of various raw materials, etc., and achieve the effect of convenient and quick replacement of screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

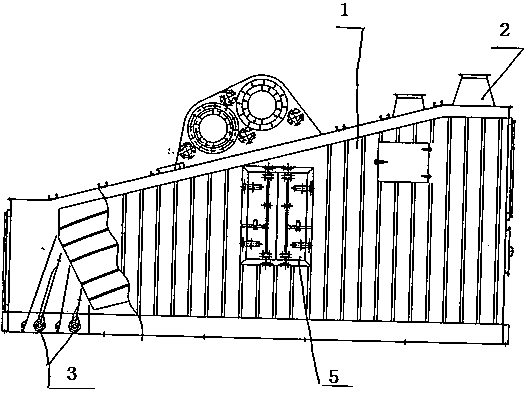

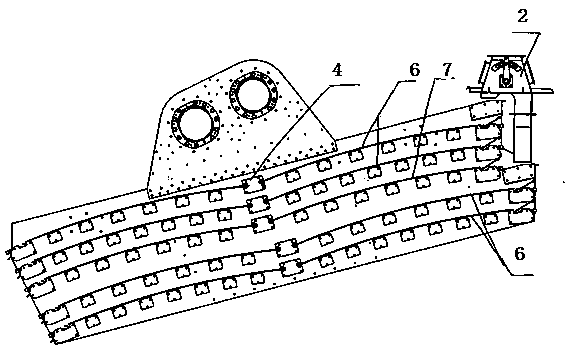

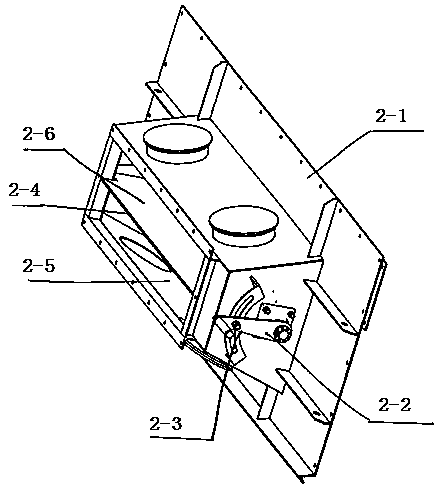

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, which includes a sand and gravel vibrating screen, an inspection door 5 is provided on the side of the screen body 1 of the vibrating screen, and a manual feeding device 2 is installed on the feed port of the screen body. A manual discharge device 3 is installed in the discharge port of the sieve body, a layer of non-porous sieve plate 7 is installed on the upper middle of the screen box, and two layers of non-porous sieve plate are installed in the screen box above and below the non-porous sieve plate Screens 6, each layer of screens are composed of two groups of screens on the left and right, and the two ends of each group of screens 4-3 and the square beam 4-1 at the connection are respectively provided with arrayed round pipes 4 with dislocations butt joints -2, a screw rod 4-4 is penetrated from the middle hole of the arrayed circular tubes in each butted arrayed circular tube, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com