Wallpaper spray printing device for foaming ink

A technology for foaming ink and wallpaper, applied in the direction of printing device, printing, etc., can solve the problems of falling flatness of wallpaper, falling off of ink particles, affecting the quality and effect of wallpaper, etc., to improve stability, save energy, and improve speed and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

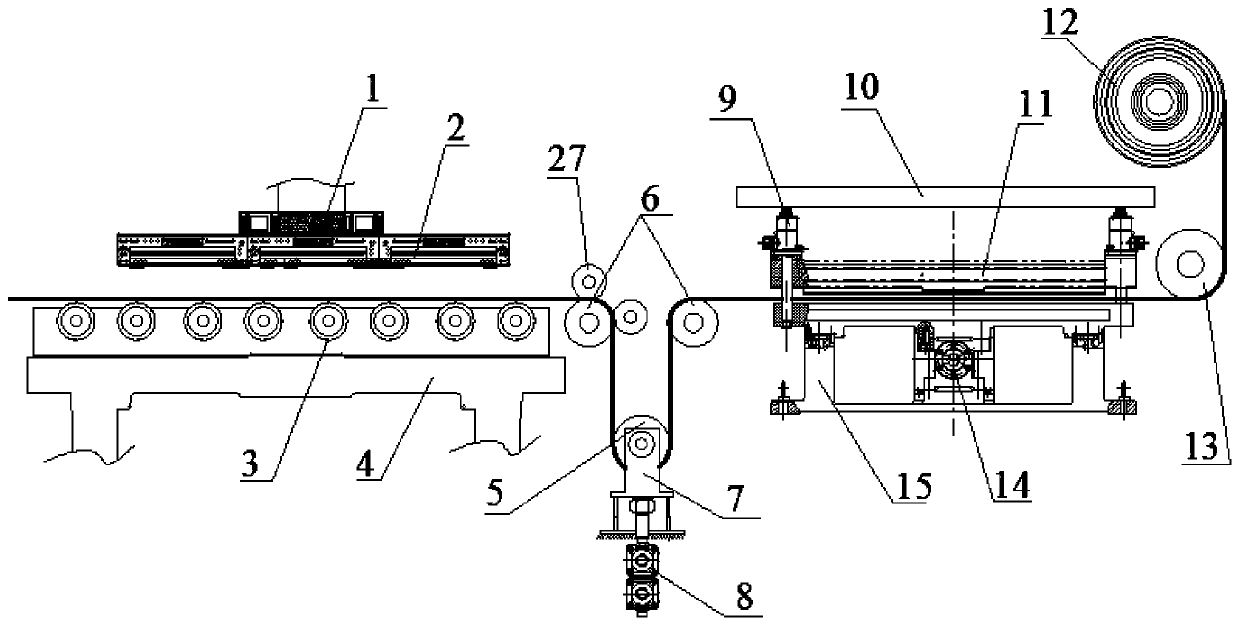

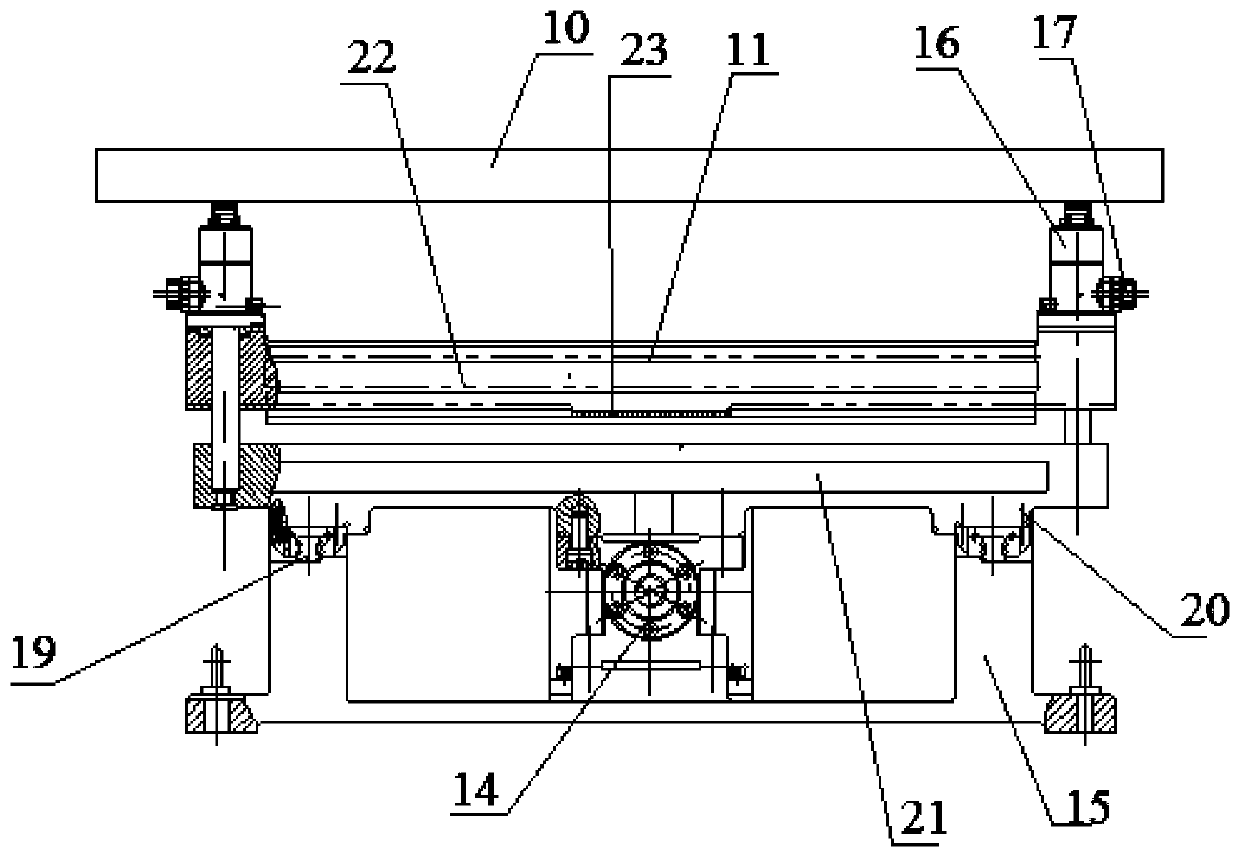

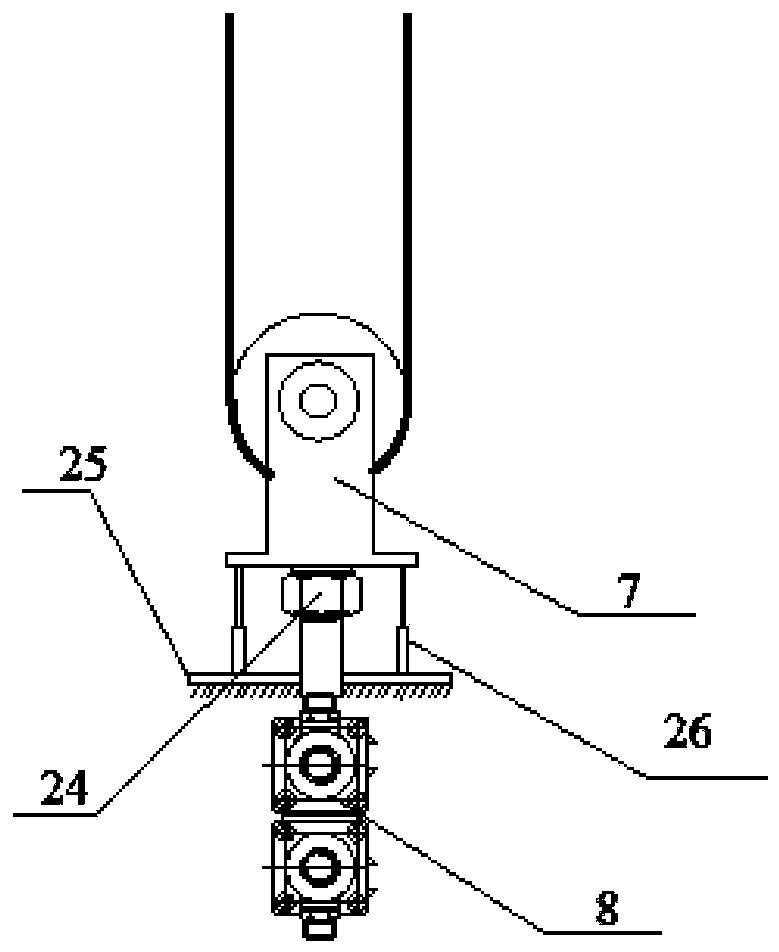

[0022] see Figure 1~4 , in an embodiment of the present invention, a foaming ink wallpaper printing device, which includes a printing head assembly 2, a conveying assembly, a drying assembly and a take-up roller 12, wherein, the bottom of the printing head assembly is provided with The conveying assembly, the drying assembly is arranged in front of the conveying assembly, the wallpaper to be printed is unrolled and conveyed by the unwinding reel, the conveying assembly, and after being sprayed by the printing head assembly 2, The drying assembly is wound on the winding roller 12; the drying assembly includes an upper drying tray mechanism, a lower drying tray mechanism, and a hot gas circulation and control mechanism, and the upper drying tray mechanism is located at the Above the wallpaper, the lower drying tray mechanism is located below the wallpaper, and the two ends of the hot air circulation and control mechanism are connected to the upper drying tray mechanism and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com