Garbage can uncapping mechanism without touching hands

A trash can and rotating mechanism technology, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of non-detachable, long moving stroke, easy to hide dirt and dirt on the tooth surface, and achieve convenient installation and use. Convenient and reliable, avoiding the effect of attaching dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

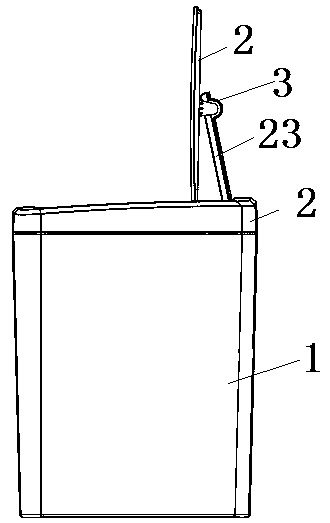

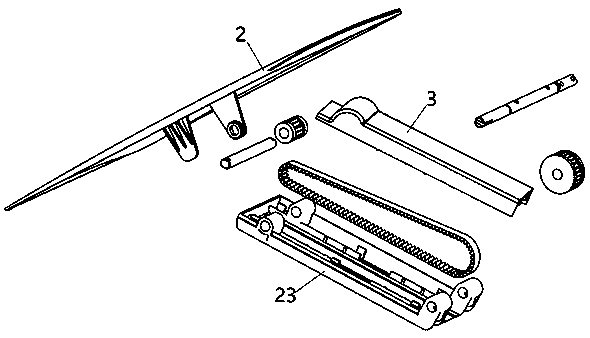

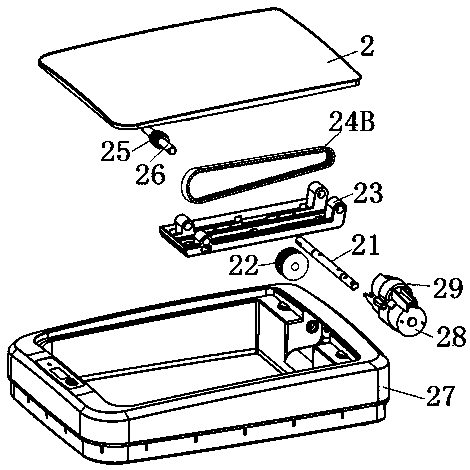

[0034] Reference attached figure 1 -Attached Figure 4 , A trash can lid opening mechanism that does not touch your hands, comprising a ring-shaped lid base 27 and a lid 2. The lid base 27 is sleeved above the trash can body 1, and also includes a lid rotating mechanism and a lid rotating mechanism Mechanism, driving mechanism and mechanism housing 3. The cover rotation mechanism includes a main rotation shaft 21 connected with the driving mechanism, a rotation arm 23 and a cover rotation shaft 26 fixed to the middle of the lower side of the barrel cover. One end of the rotation arm 23 is fixed to the main rotation shaft 21 The other end is hingedly connected to the cover shaft 26; the cover surface rotation mechanism includes a synchronous transmission belt 24B as a tooth surface transmission part, a main gear 22 sleeved on the main shaft 21 and fixedly connected to the cover base body 27, and sleeved on the cover The cover gear 25 on the rotating shaft 26 and fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com