Frame type curtain wall stand column and cross beam fast-connecting system

A fast connection, frame type technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of general installation connection speed, complicated connection structure between columns and beams, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

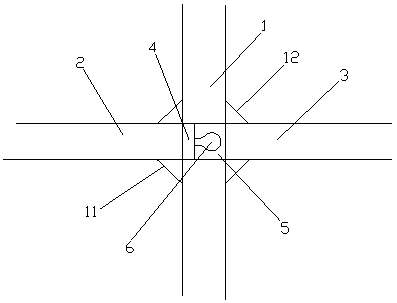

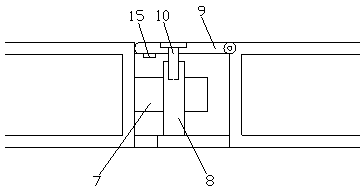

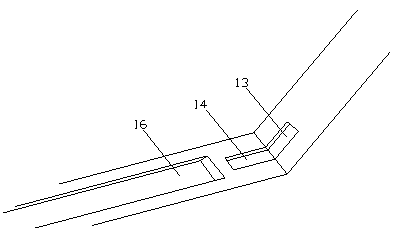

[0025] Such as Figure 1-3 As shown, a frame-type curtain wall column and beam quick connection system includes a column body 1, a left beam body 2 and a right beam body 3, and the ends of the left beam body 2 and the right beam body 3 are respectively provided with a first connecting plate 4 and the second connecting plate 5, the column body 1 is provided with a groove (not shown) that matches the first connecting plate 4 and the second connecting plate 5, and the first connecting plate 4 is provided with a splicing portion 6. The second connecting plate 5 is provided with a splicing groove (not shown) that matches the splicing portion 6, and the ends of the first connecting plate 4 and the second connecting plate 5 are connected through the splicing portion and the splicing groove, so The left beam body 2 is provided with a first tenon 7, the back of the second connecting plate 5 is provided with a second tenon 8, and the column body 1 is provided with a first tenon matching...

Embodiment 2

[0028] Such as Figure 1-3As shown, a frame-type curtain wall column and beam quick connection system includes a column body 1, a left beam body 2 and a right beam body 3, and the ends of the left beam body 2 and the right beam body 3 are respectively provided with a first connecting plate 4 and the second connecting plate 5, the column body 1 is provided with a groove (not shown) that matches the first connecting plate 4 and the second connecting plate 5, and the first connecting plate 4 is provided with a splicing portion 6. The second connecting plate 5 is provided with a splicing groove (not shown) that matches the splicing portion 6, and the ends of the first connecting plate 4 and the second connecting plate 5 are connected through the splicing portion and the splicing groove, so The left beam body 2 is provided with a first tenon 7, the back of the second connecting plate 5 is provided with a second tenon 8, and the column body 1 is provided with a first tenon matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com