frame mining method

A mining method and frame-type technology, which are applied in the field of frame-type mining, can solve the problems of ore powder dilution, large losses, and large safety risks, and achieve the effects of reducing dilution losses and improving operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

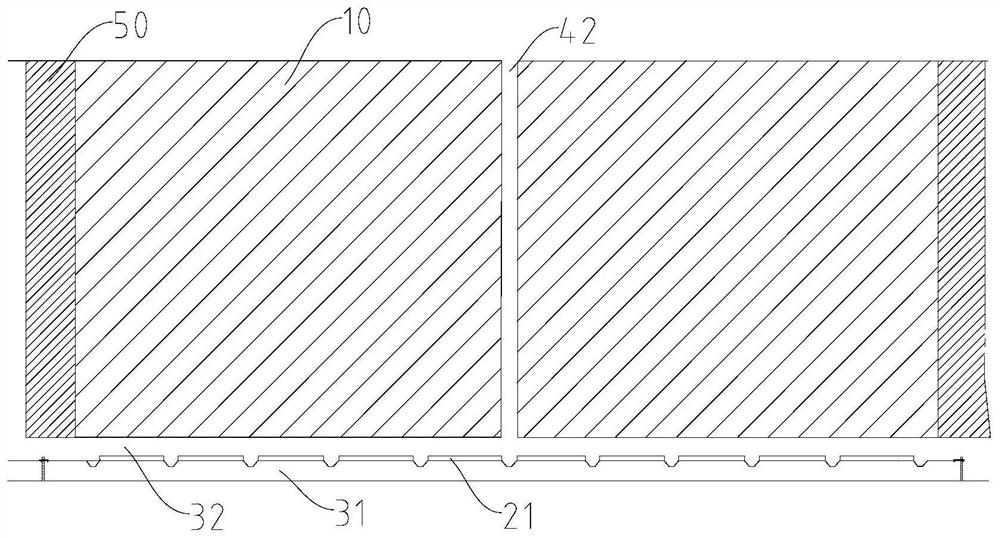

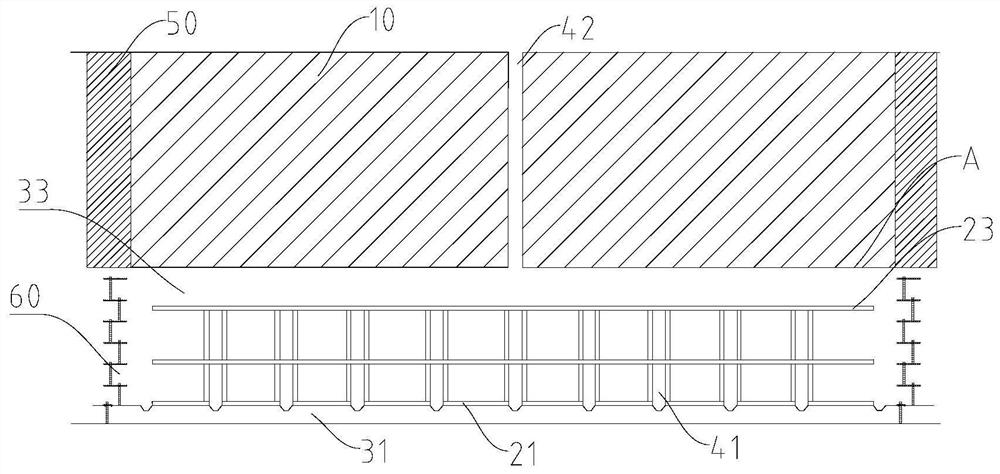

[0033] In this disclosure, unless otherwise stated, the used orientation words such as "upper" and "lower" refer to the upper and lower of the actual orientation of the stope. For details, please refer to Figure 2 to Figure 5 direction of the drawing.

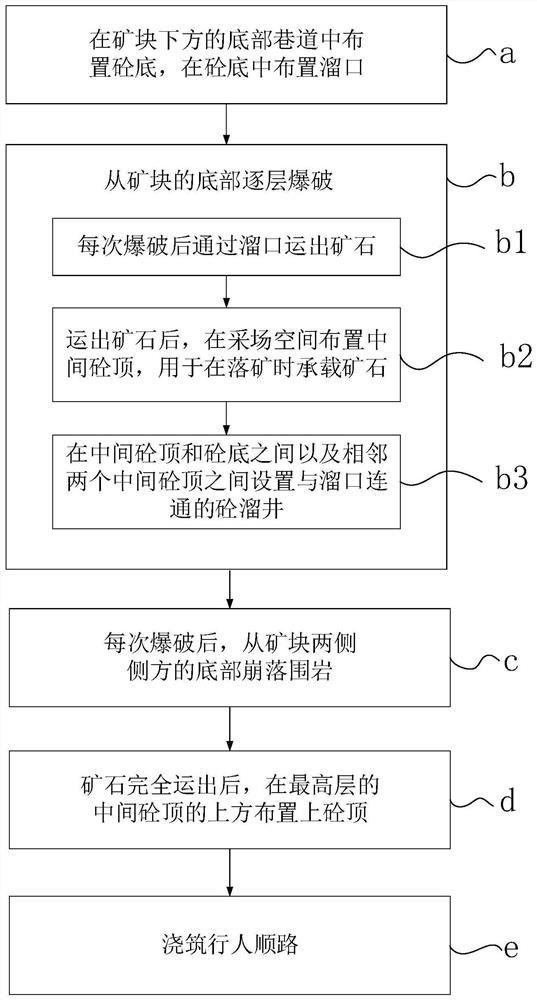

[0034] First of all, it needs to be explained that when mining, refer to figure 2 Firstly, a vertical sky shaft 42 is opened from the middle of the ore block 10 for ventilation and as a transportation channel, and a bottom roadway is provided at the bottom of the ore block 10 for transporting the collapsed ore after mining. The method provided in the present disclosure is applied after the raised shaft 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com