Mining method of segmental collapse and bottom structure followed by continuous filling

A backfill mining method and bottom structure technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of complex mining process, high mining cost and low mining efficiency, and achieve safe, efficient and low-cost mining and reduce exposure time. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

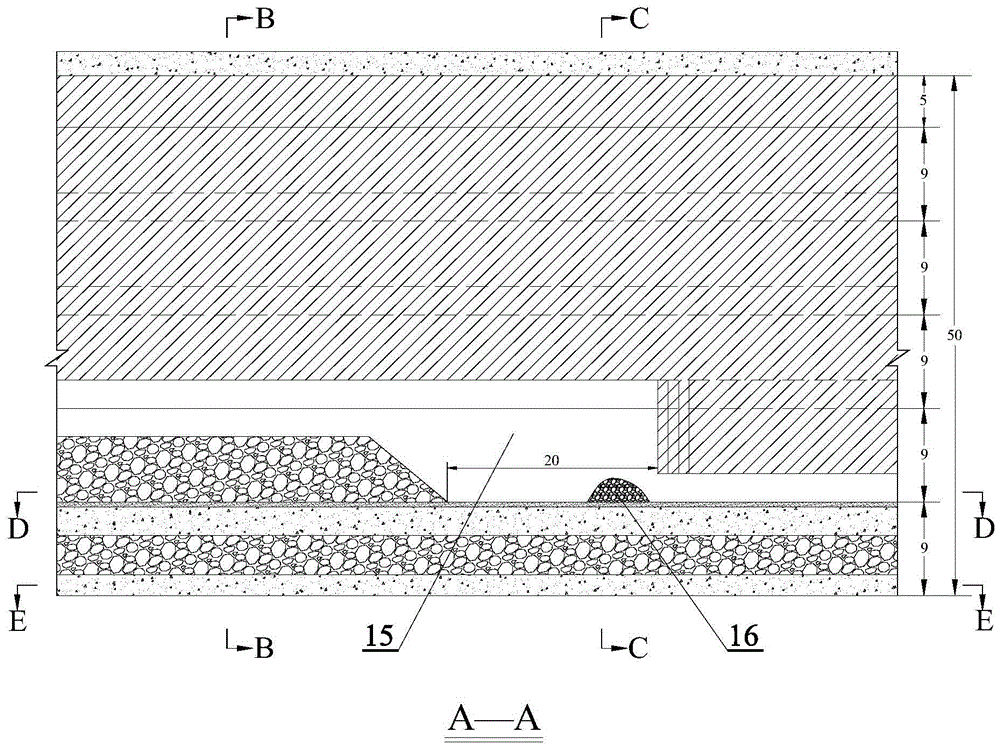

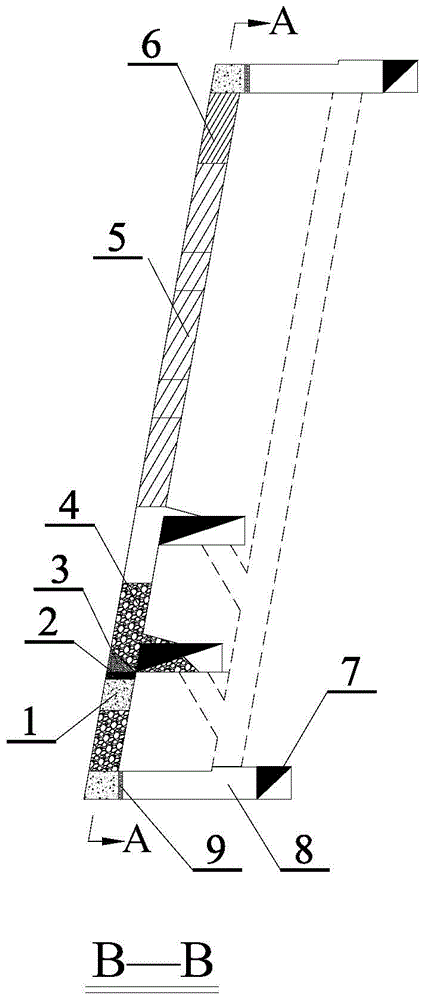

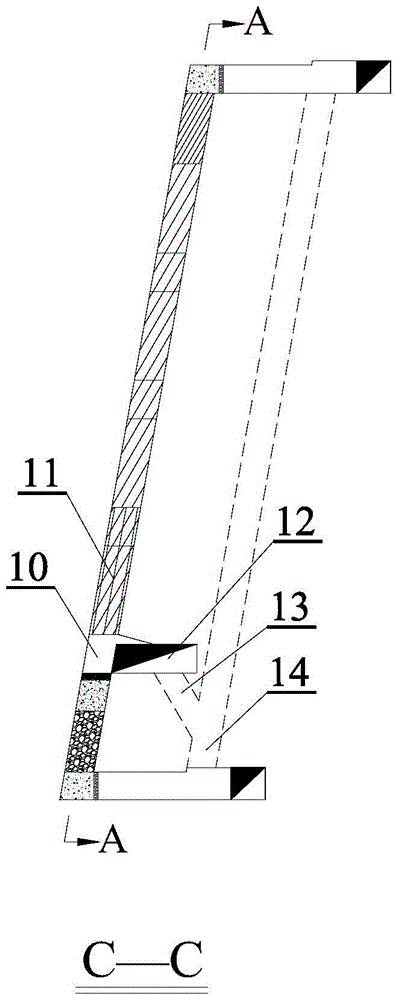

[0024] The bottom structure of subsection collapse mine provided by the present invention follows and forms the continuous filling mining method, and the technical scheme is as follows:

[0025] (1), the vein is divided into the middle section along the height direction, and then divided into subsections in the middle section, and the full length of the vein in the section is used as a mining unit to continuously advance from one end of the vein to the other end;

[0026] (2) Adopt quasi-system of out-of-vein mining. When mining in the first section, excavate the ore from the stage transportation roadway at a certain distance to reach the ore body; when mining in other sections, arrange the ore output in sections along the direction of the ore body Space, each sub-section of the ore space is connected to each other through sub-sections and inclined shafts;

[0027] (3) Excavate the rock-drilling roadway and cut the raised well at the bottom of the first section to provide rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com