Mining method of waste rock filling with artificial concrete retaining wall reconstructed inter-column

A technology of filling mining and concrete, which is applied in the direction of filling materials, ground mining, mining equipment, etc., can solve the problems of unstable supply of filling materials, affect the normal mining of mines, increase filling costs, etc., and achieve large production capacity, high recovery rate, The effect of small amount of mining and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

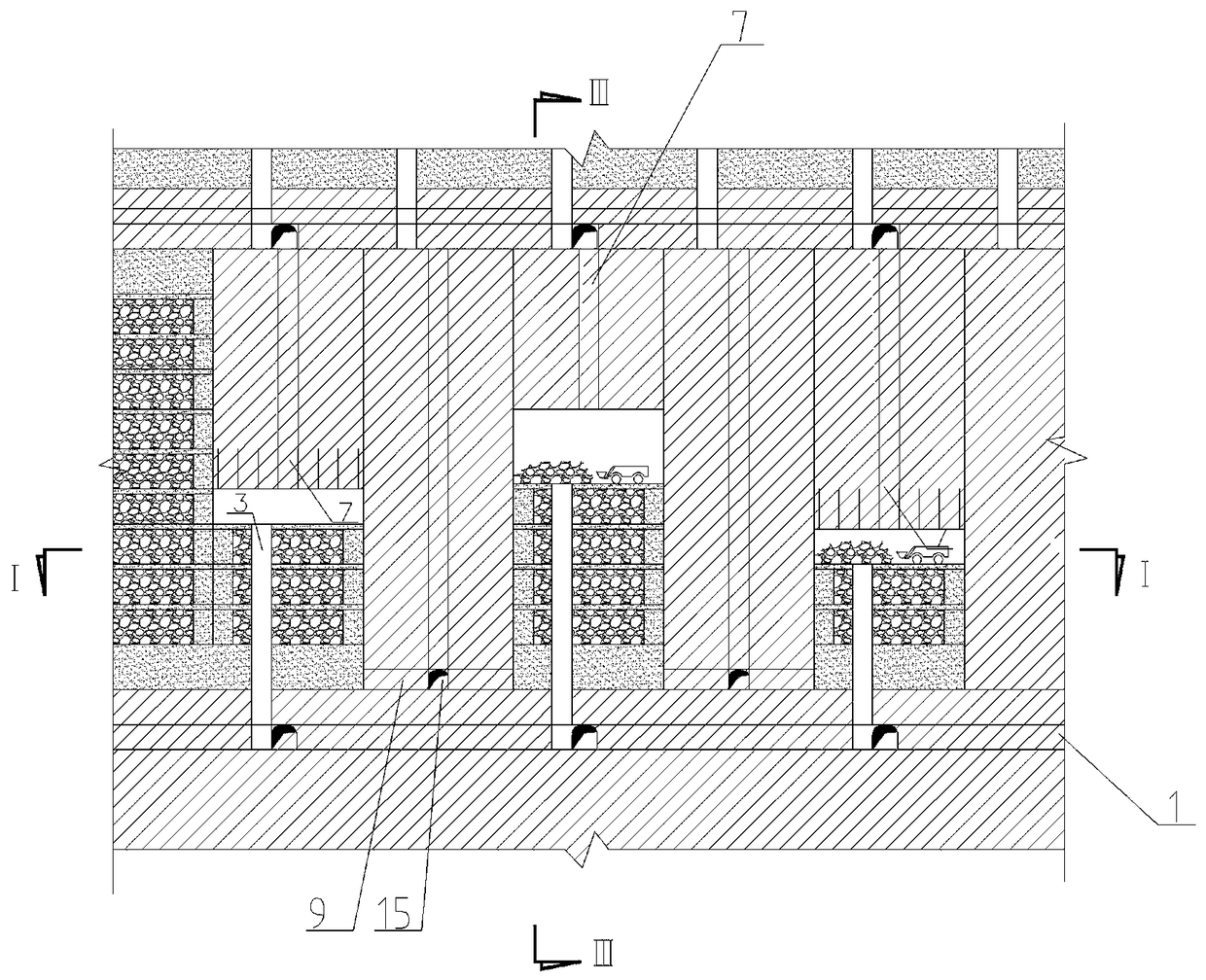

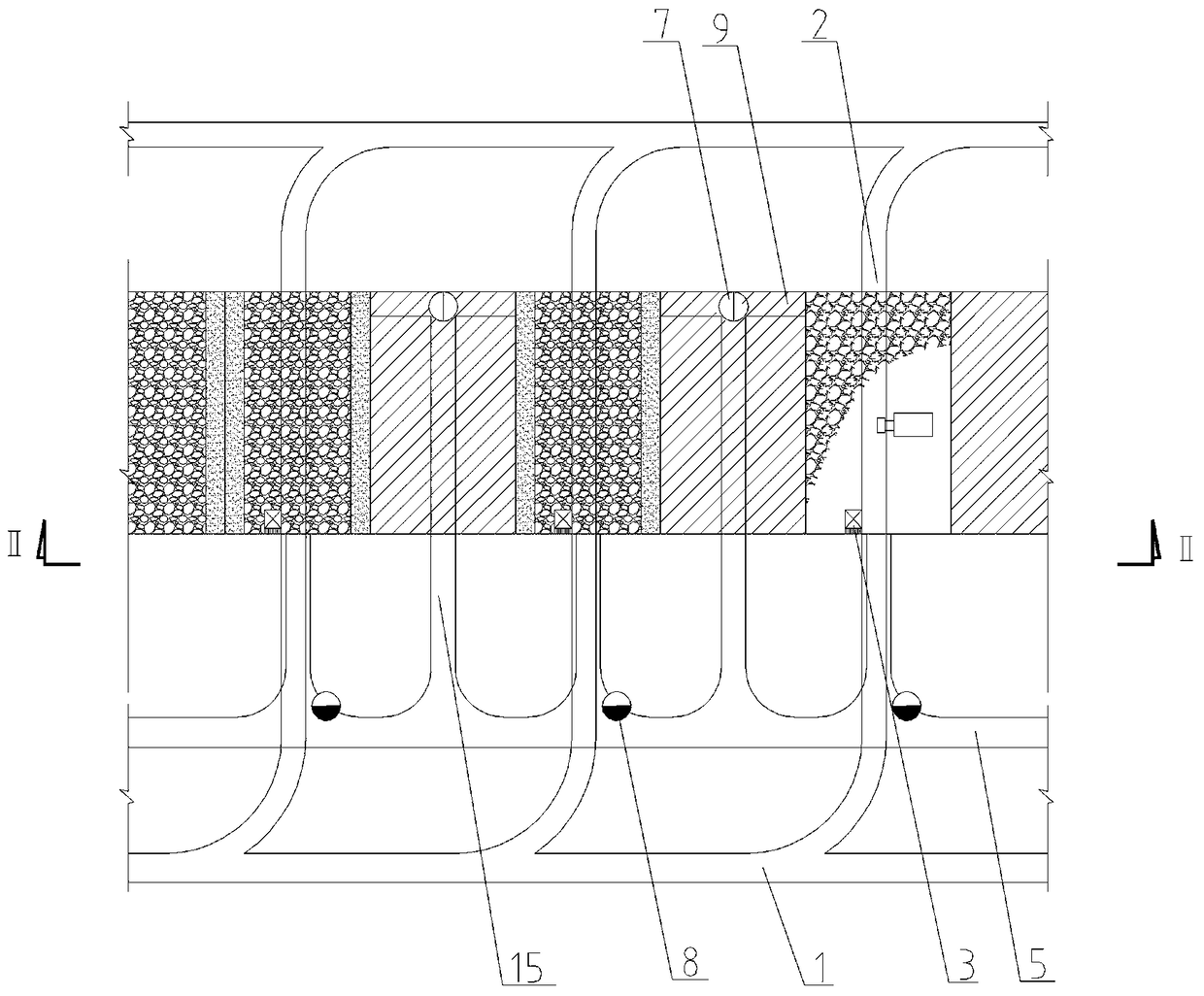

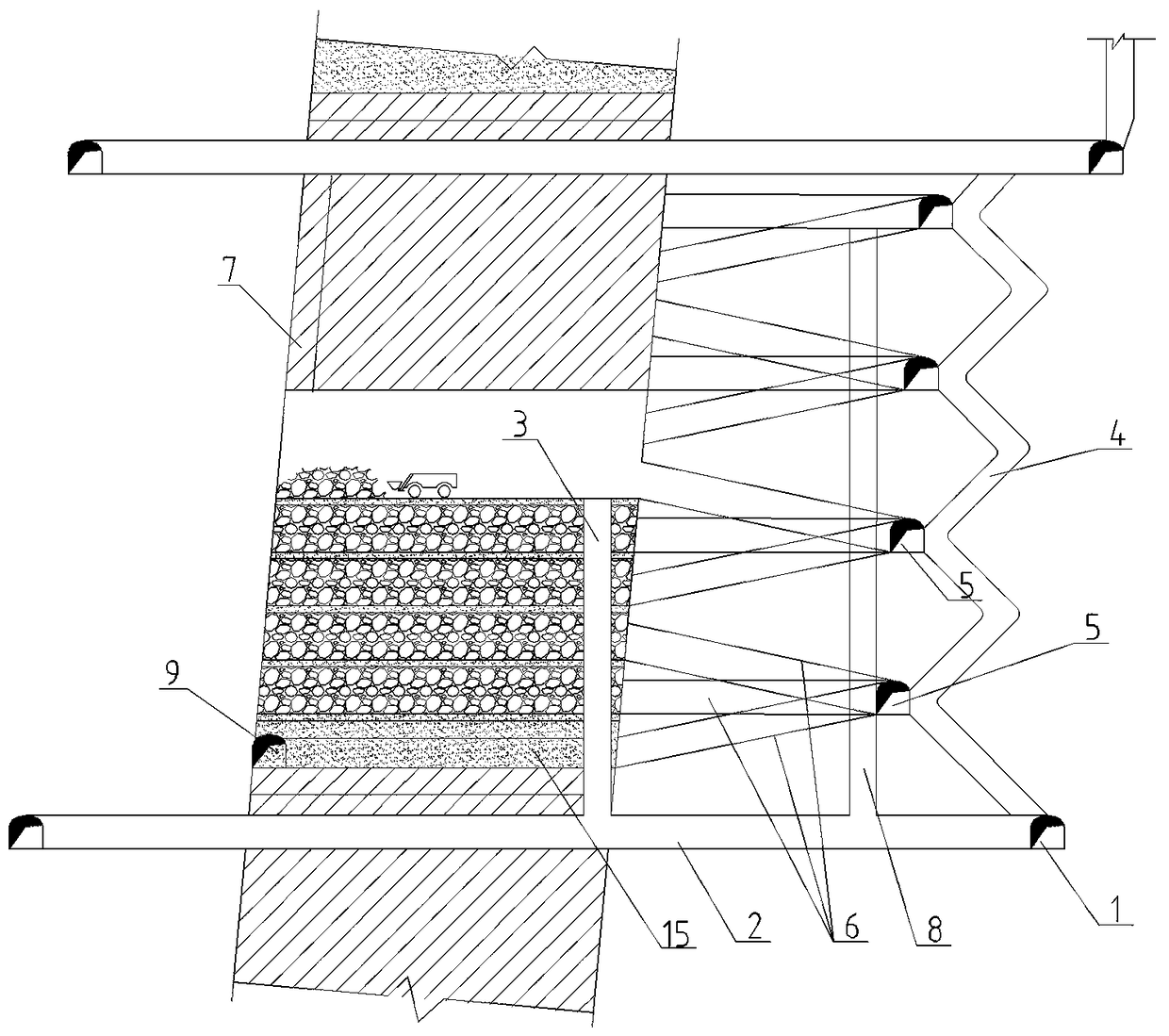

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Taking a tin-polymetallic mine in Guangxi Autonomous Region of my country as an example, the ore body is a complex and irregular vein-like body. The lower part is an irregular vein-shaped main body, and the main ore body belongs to the steeply inclined medium-thick to thick large ore body. The average inclination angle of the ore body is 53°, the average thickness is 22m, the ore body is stable, and the surrounding rock is reef limestone with bioclastic structure and massive structure. The rock quality of the reef limestone is medium to good, and the rock mass is medium to relatively complete. Generally, the roadway does not need support.

[0024] The main technical and economic indicators of mining the ore body by this method: stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com