Electric fan

An electric fan and fan technology, applied in the field of electric fans, can solve the problem of difficult control of the locking torque of the bracket for installing the motor casing and fan blades, and achieve the effects of stable size, stable installation, and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

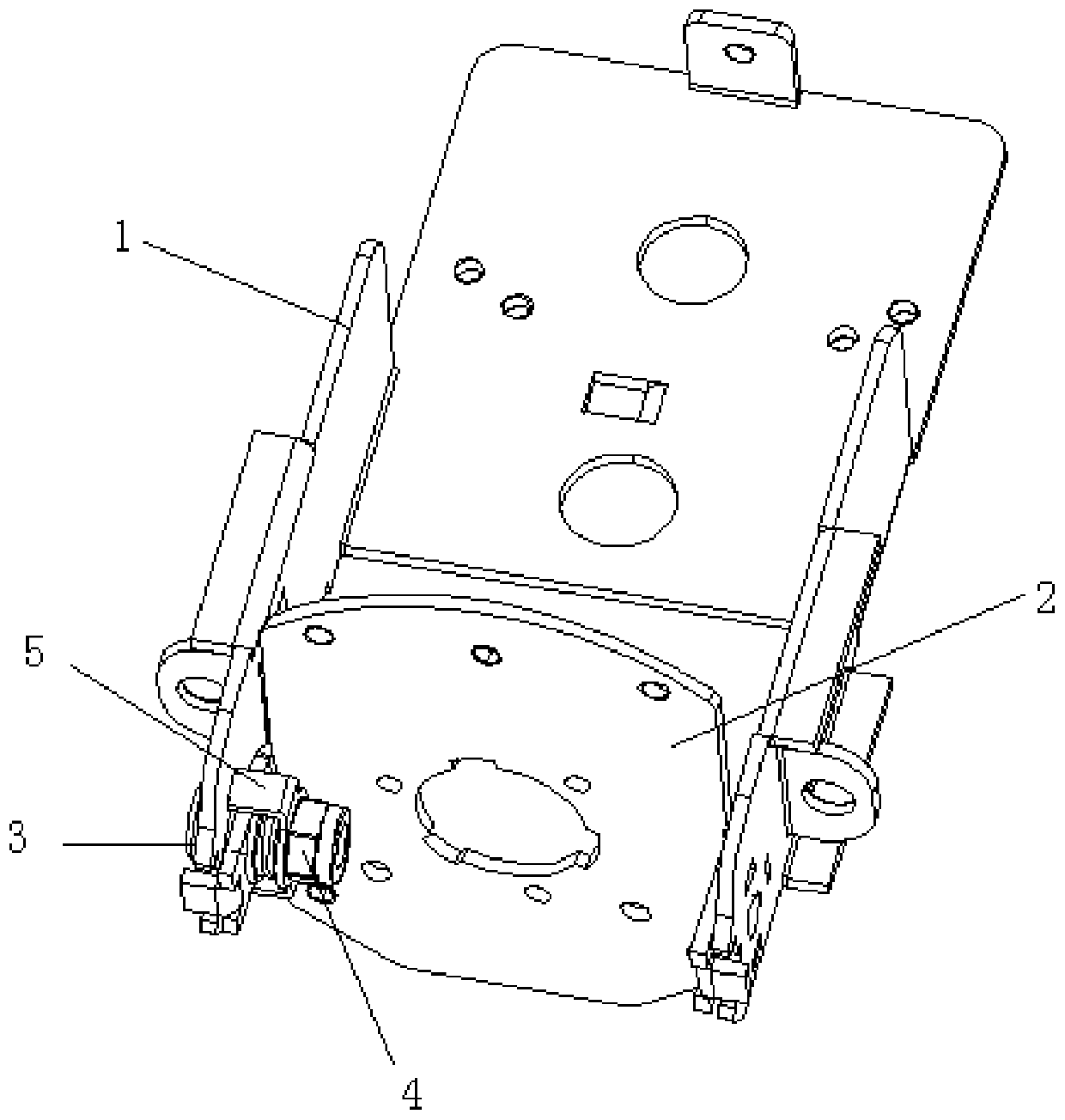

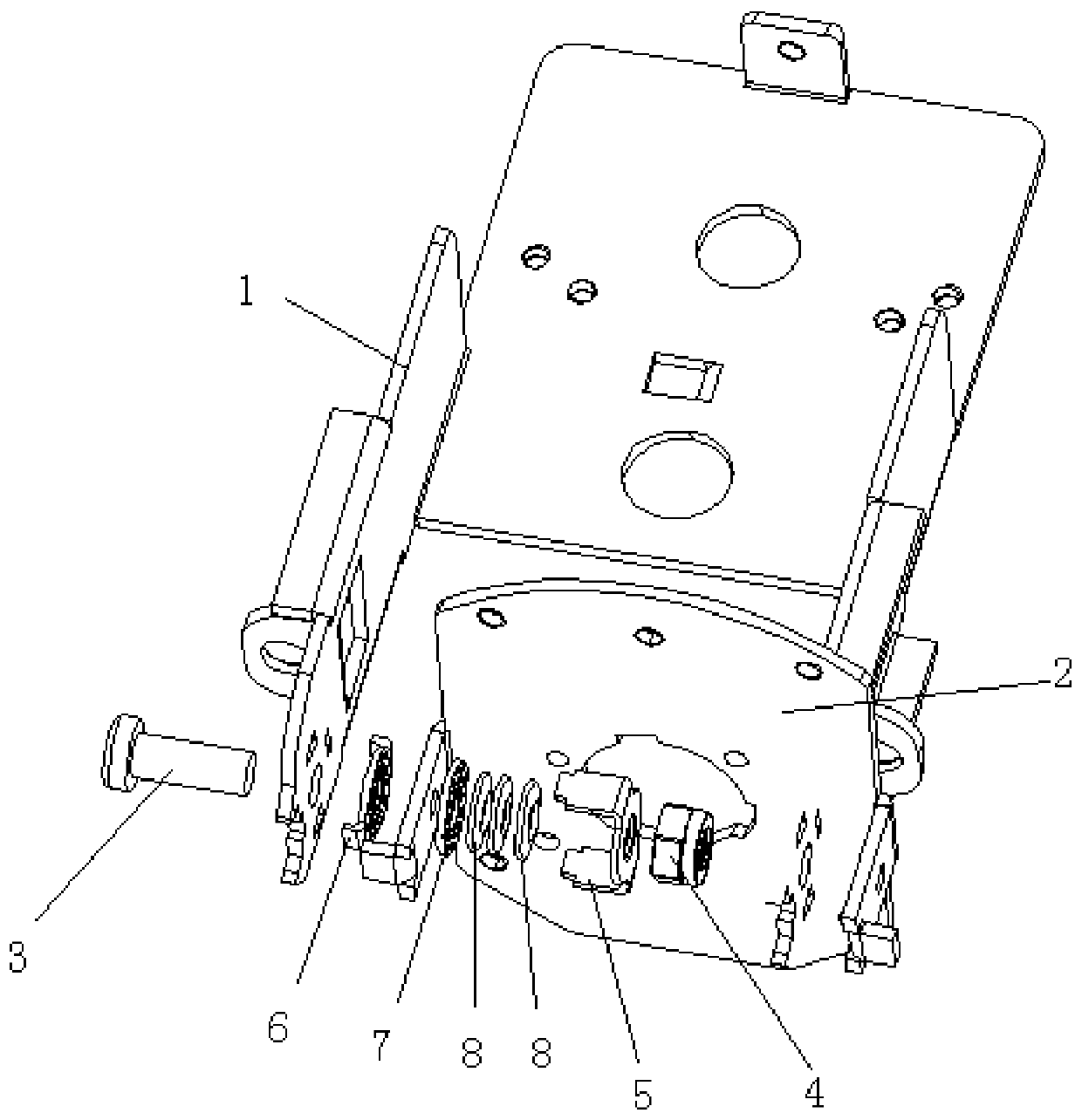

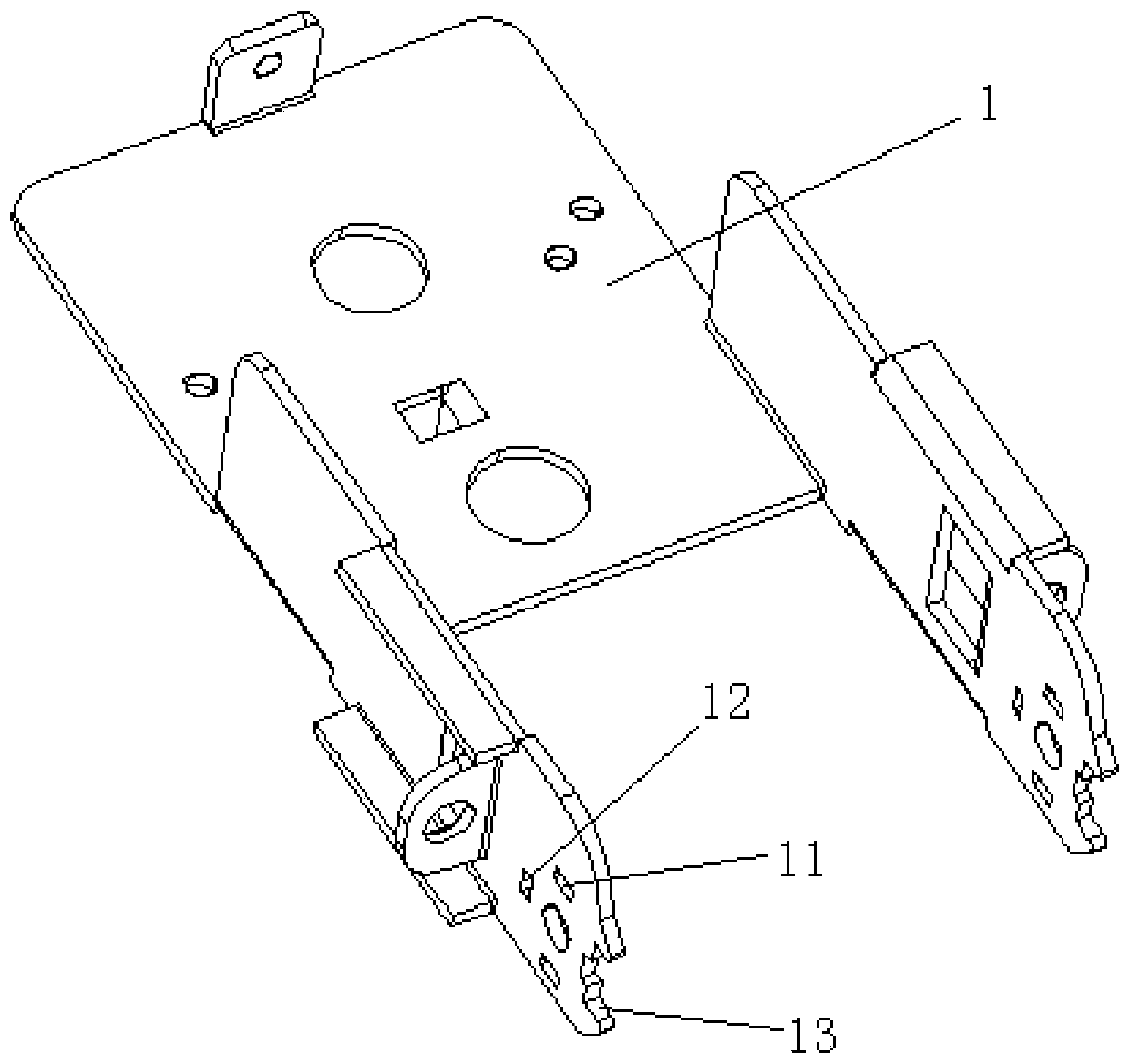

[0054] This embodiment provides a specific implementation of an electric fan, such as Figure 1 to Figure 7 As shown, it includes a first bracket 1 , a second bracket 2 , a fastener 4 , and a stopper 5 .

[0055] Wherein the first bracket 1 is suitable for being fixedly connected with the fuselage, and during the working process, the first bracket 1 is fixed; Rotationally connected to the first bracket 1, the fan head includes a motor that drives the fan blades to rotate, and the fan blades, the rotation of the second bracket 2 specifically refers to the rotation within a certain angle range in the vertical plane; the fastener 4 It is used to fix the second bracket 2 on the hinge shaft 3; the stopper 5 is connected to the first bracket 1, and is located between the first bracket 1 and the fastener 4, with To limit the distance between the fastener 4 and the first bracket 1 , the second bracket 2 is limited between the first bracket 1 and the limiting member 5 .

[0056] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com