Lamination type fire hole assembly

A lamination type, fire hole technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problems of poor combustion and large fire hole, etc., to improve the deterioration of exhaust emissions, the stability of combustion flame, and the stability of expansion. The effect of the burn zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

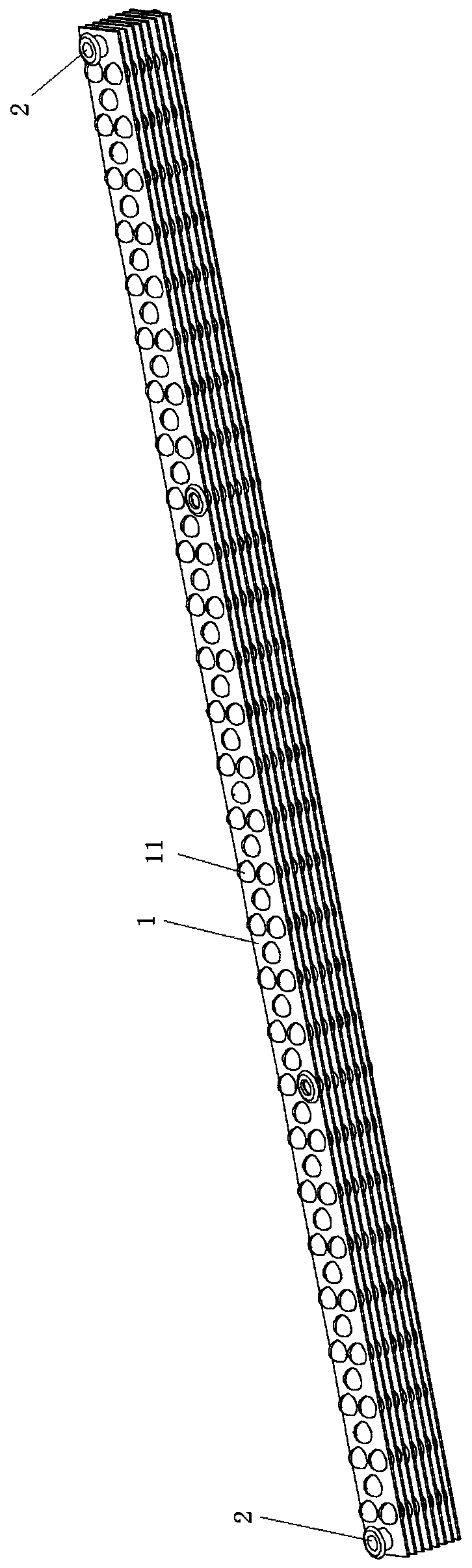

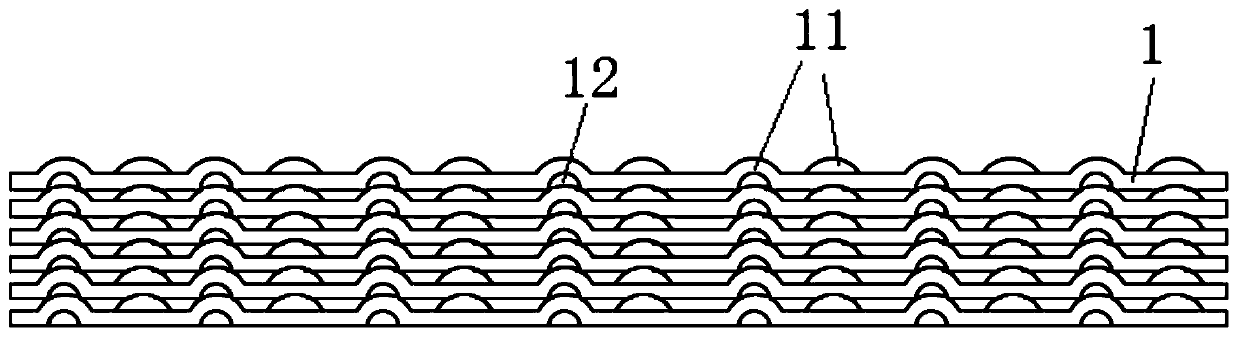

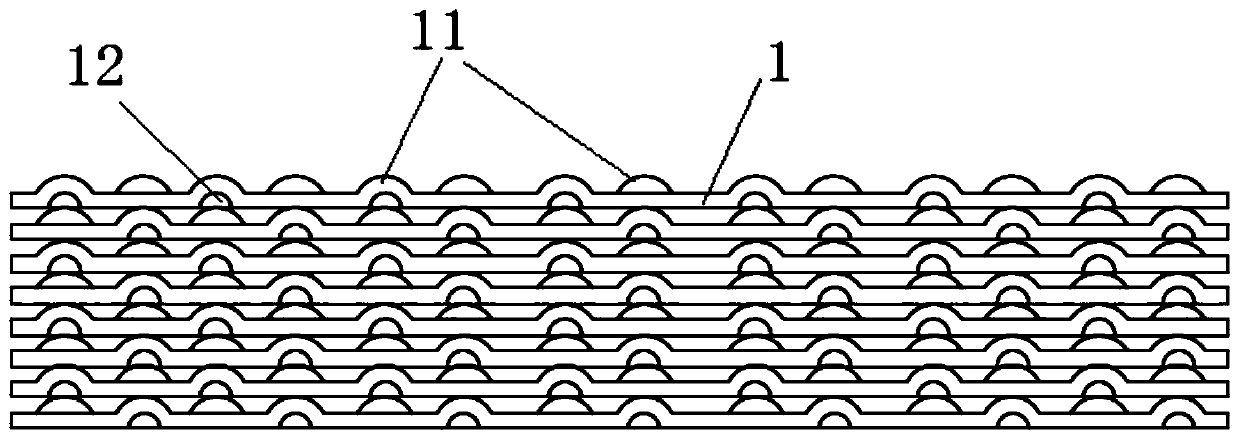

[0030] Embodiment 1 of the present invention provides a laminated fire hole assembly, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, for a burner, the fire hole assembly includes several laminations 1 stacked on top of each other, and the front of each lamination 1 is provided with several convex parts 11 facing in the same direction, each of the laminations 1 Recesses 12 are provided at positions corresponding to the protrusions 11 on the back of the sheet 1 , and the protrusions 11 and the inner recesses 12 disposed on adjacent laminations 1 correspond to each other.

[0031] By adopting the above-mentioned fire hole assembly, its depth is longer, and the loss of long-term combustion sublimation will not affect the size change of the fire hole, and the thin plate at the non-fire hole position plays a role of stabilizing the flame, making the combustion flame more stable; In addition, through The fire hole assembly with the structure of the pres...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a laminated fire hole assembly for burners. The fire hole assembly includes several laminates 1 stacked on top of each other. The front of each of the laminates 1 is provided with a There are several convex parts 11 on the back side of each lamination 1 corresponding to the position of the convex part 11, and an inner concave part 12 is provided at the position corresponding to the protruding part 11, and the convex part provided on the adjacent lamination 1 The raised portion 11 corresponds to the inner concave portion 12 .

[0042] By adopting the above-mentioned fire hole assembly, its depth is longer, and the loss of long-term combustion sublimation will not affect the size change of the fire hole, and the thin plate at the non-fire hole position plays a role of stabilizing the flame, making the combustion flame more stable; In addition, through The fire hole assembly with the structure of the present invention also imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com