Constant-temperature and constant-pressure measuring device for flow of component

A measuring device, a technology of constant temperature and constant pressure, applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of inaccurate measurement results, inability to effectively control flow, pressure, temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

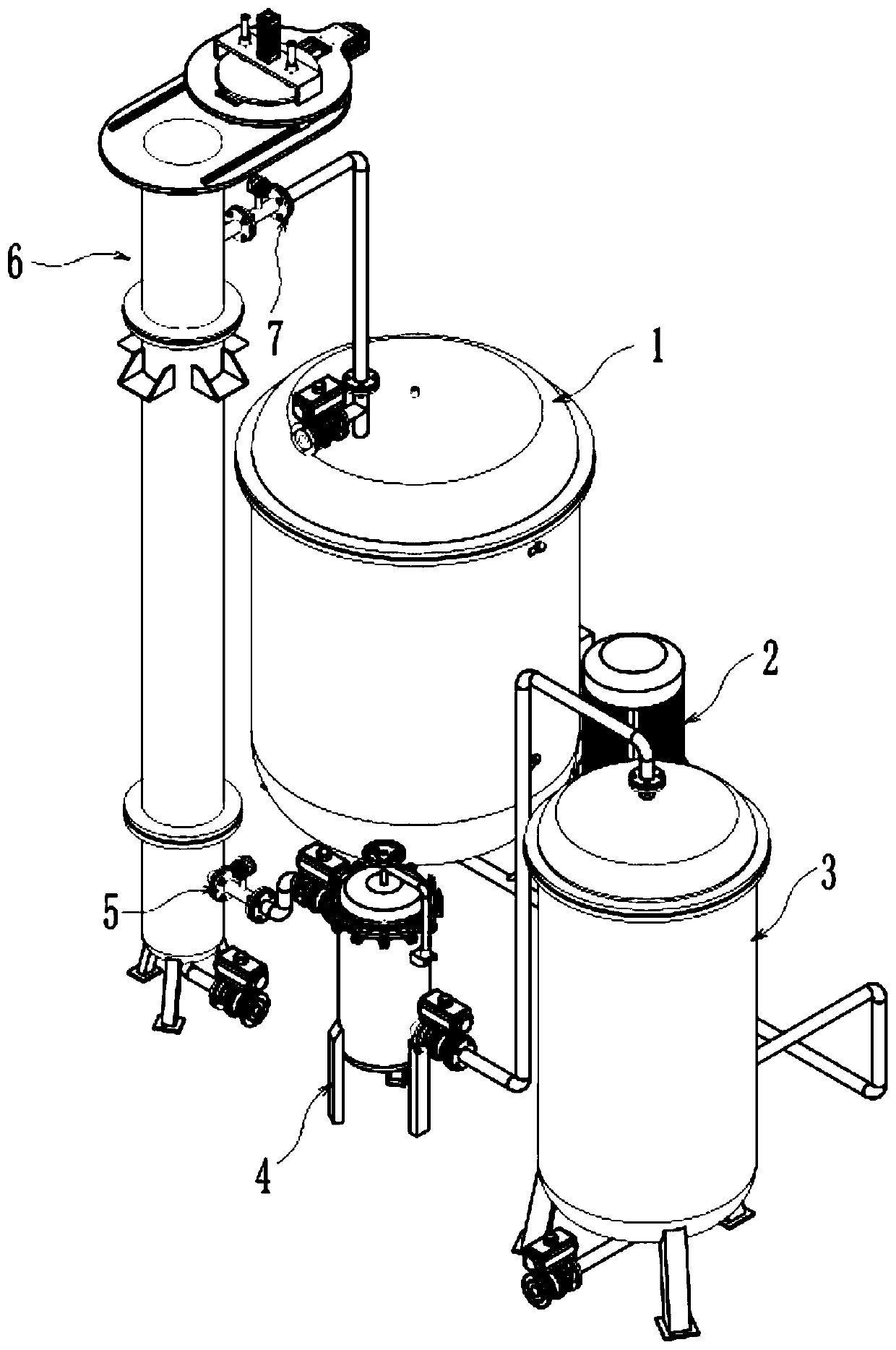

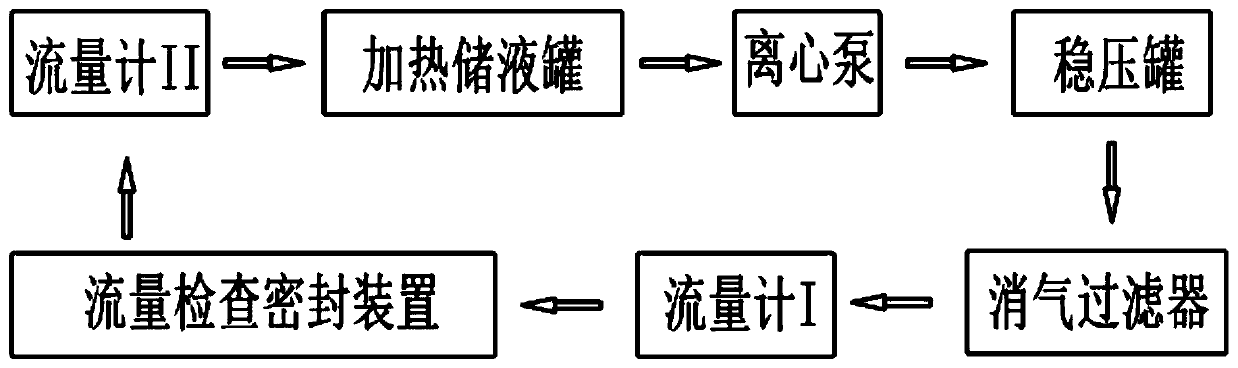

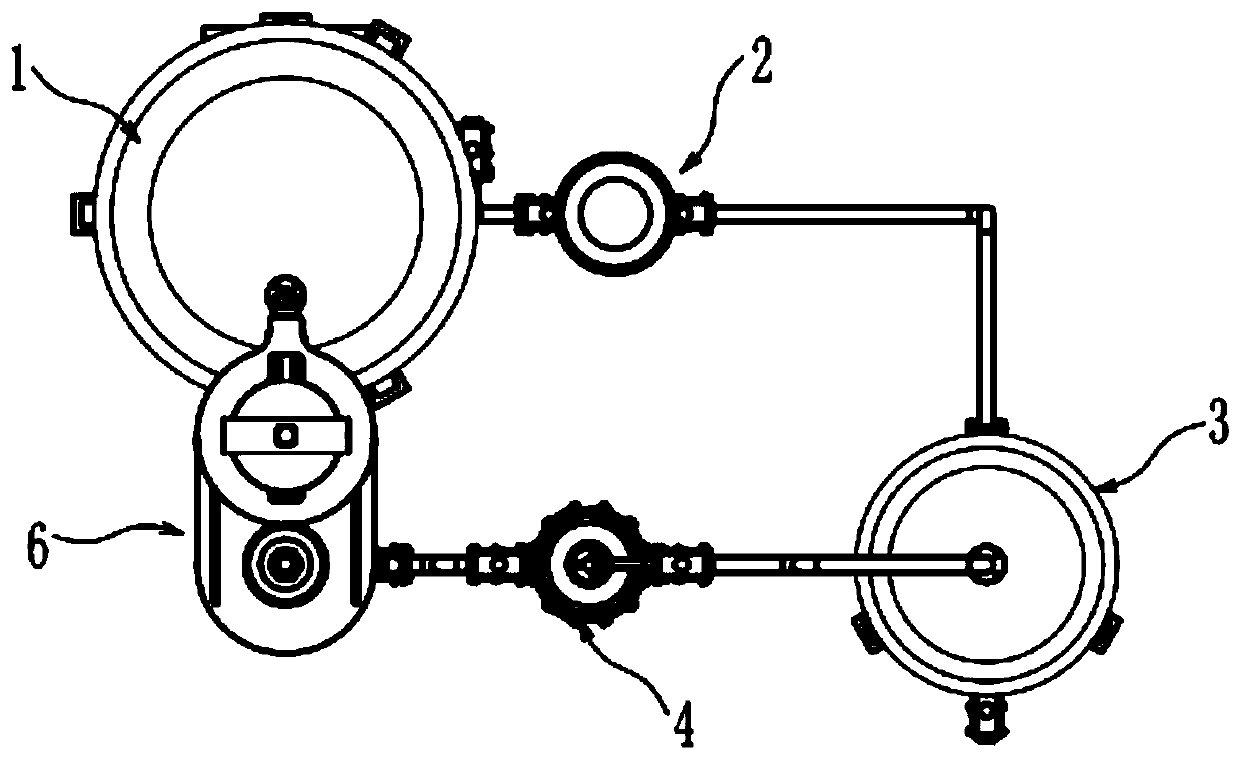

Embodiment 1

[0019] see Figure 1~3 , in the embodiment of the present invention, a constant temperature and constant pressure measuring device for component flow, including a heating liquid storage tank 1, a centrifugal pump 2, a pressure stabilizing tank 3 and a flow checking sealing device 6 connected in sequence to form a liquid phase cycle, in this implementation In an example, the heating liquid storage tank 1 is used to store the liquid phase and heat it so that the temperature of the liquid phase is constant, and the centrifugal pump 2 is used to pump the liquid phase in the heating liquid storage tank 1 into the surge tank 3 Inside, preferably, the centrifugal pump 2 is a multi-stage centrifugal pump; the surge tank 3, obviously, is used to ensure that the pressure of the liquid phase output to the flow inspection sealing device 6 is stable; the flow inspection sealing device 6 is used for Place the parts to be measured, and connect the inlet and outlet of the parts with the heati...

Embodiment 2

[0022] see Figure 1~3 , in an embodiment of the present invention, a component flow constant temperature and constant pressure measuring device includes a heating liquid storage tank 1, a centrifugal pump 2, a pressure stabilizing tank 3 and a flow inspection sealing device 6 connected in sequence to form a liquid phase cycle. Valves are installed on the pipelines between the liquid storage tank 1, the centrifugal pump 2, the surge tank 3 and the flow inspection sealing device 6. Preferably, the valves are electromagnetic valves, which are convenient for automatic control.

[0023] In order to realize the connection of the pipelines conveniently, the pipelines between the heating liquid storage tank 1, the centrifugal pump 2, the surge tank 3 and the flow inspection sealing device 6 are all equipped with quick joints to realize convenient and fast connection, which is convenient Rapid setup of the entire detection setup.

[0024] Combining Examples 1-2, it is easy to know th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com