Automatic regulating device for flow pressure of gas chromatograph

A gas chromatograph, automatic adjustment technology, applied in the field of analytical instruments, can solve the problem that the flow rate of the gas chromatograph cannot be automatically controlled, and achieve the effect of low cost and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

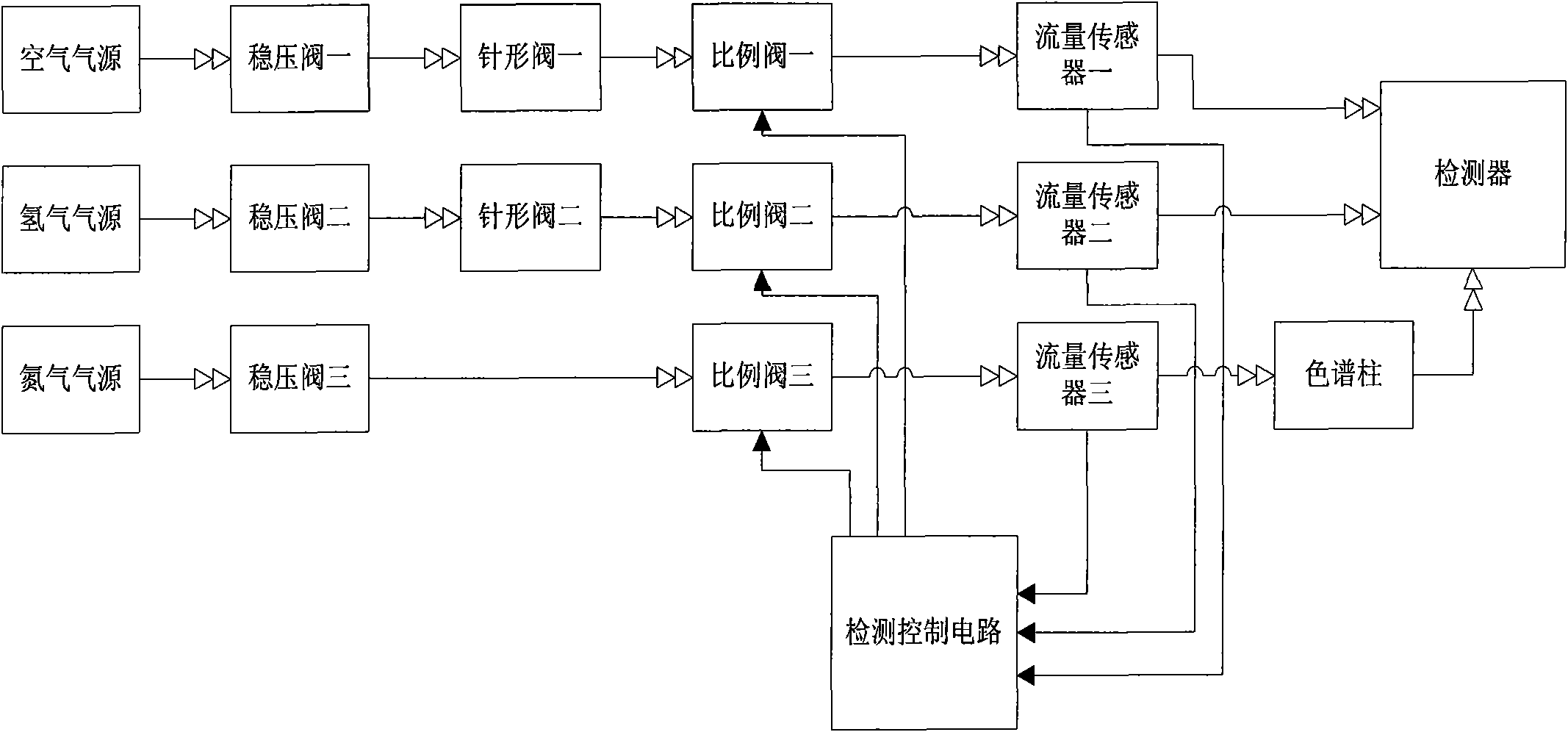

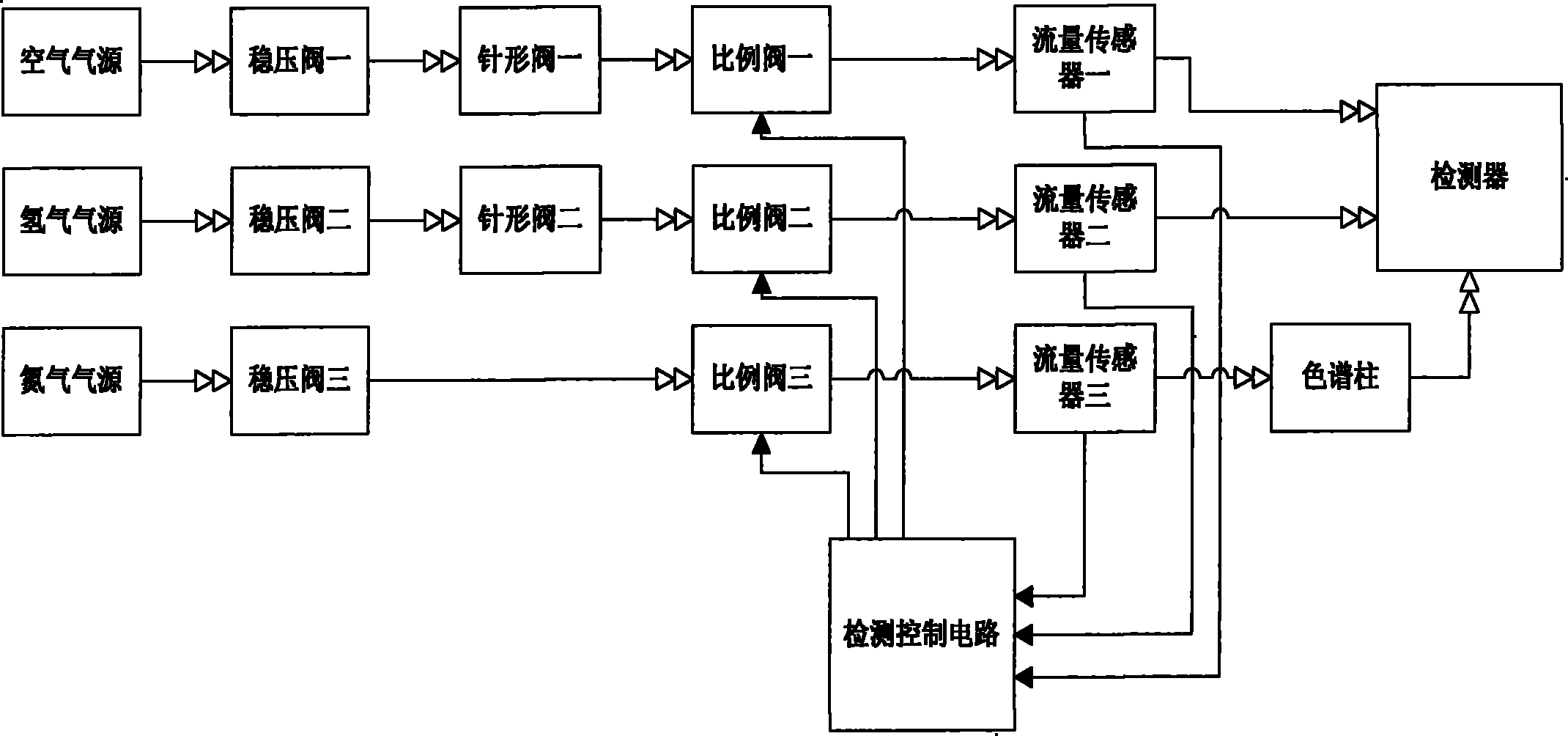

[0008] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] In order to realize the technical problem of automatic control and display of three-way flow and pre-column pressure in a gas chromatograph (FID), an automatic flow pressure adjustment device is provided according to the following technical scheme. The regulating device includes a pressure stabilizing valve, a needle valve, a proportional valve, a flow sensor, a pressure sensor, and a detection control circuit. The circuit includes a single-chip CPU, an analog-to-digital conversion chip A / D, a digital-to-analog conversion chip D / A, a driver chip DR, a communication interface, and a power supply; wherein the single-chip microcomputer accepts the flow (pressure) setting value through the communication interface, and the single-chip microcomputer passes through according to the set value. Analog-to-digital conversion chip, dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com