Cement paste system choosing method capable of preventing oil, gas and water from channeling

A cement slurry, oil-gas-water technology, which is applied in chemical instruments and methods, earthwork drilling, and drilling compositions, etc., can solve the problems of affecting the quality of cement slurry in the oil zone, long cement slurry solidification time, and high probability of water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

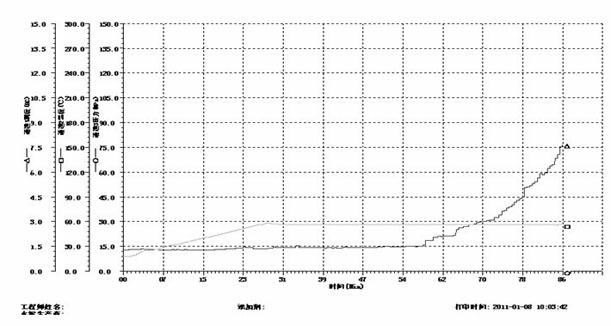

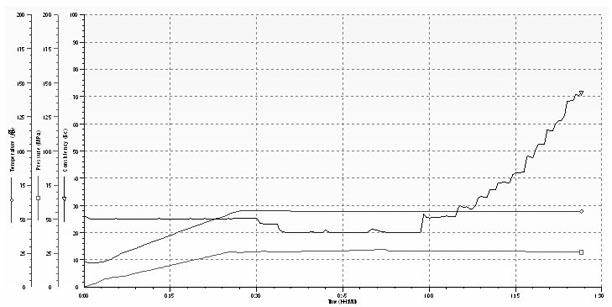

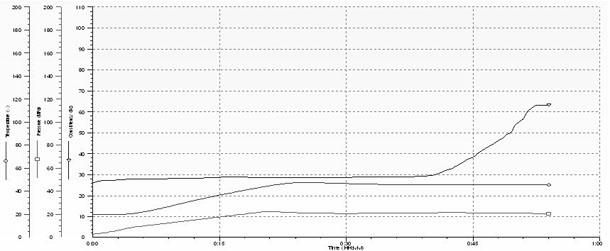

Image

Examples

Embodiment Construction

[0025] A method for selecting a cement slurry system for preventing oil, gas and water channeling, which selects the cement slurry system according to the following conditions.

[0026] (1) For the target layer with short oil layer sealing section and shallow oil reservoir depth, the formula of quick-setting early-strength cement can be used. On the premise of ensuring the safety of cementing construction, its shorter thickening time and shorter Strong thixotropy, the cement slurry can quickly hydrate and solidify after being injected into the target layer quickly, forming a strong early strength and preventing the formation fluid from invading.

[0027] Quick-setting early-strength cement slurry formula: G-grade cement + (accounting for cement weight: water-locking agent × 2% + drag reducer × 0.2%), water-cement ratio 0.44, 55°C, 25MPa, initial consistency 26BC, thickening time 50Min .

[0028] (2) For the target layer with complex formation, abnormal interlayer pressure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com