Gas-solid two-phase erosion wear testing device

A wear test, gas-solid technology, applied in the direction of testing wear resistance, etc., can solve the problems of long warm-up and stabilization time, long transmission pipeline of gas-solid two-phase flow of components, complex system and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

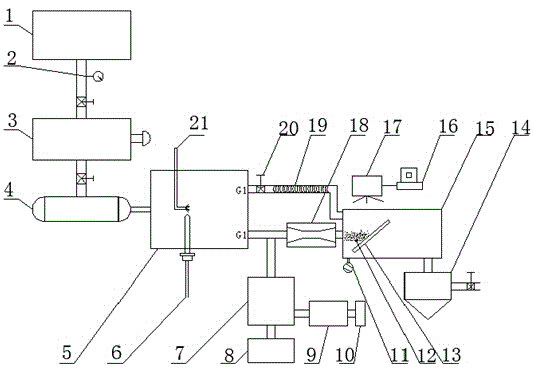

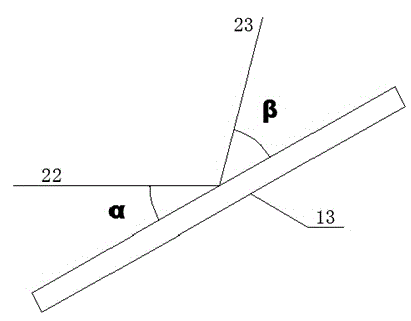

[0016] Such as figure 1 , figure 2 As shown, the structure of the present invention is: the first compressor 1 is connected to the combustion chamber 5 through the surge tank 3 and the drier 4, the outlet of the first compressor 1 is connected to the pressure gauge 2, and the fuel nozzle 21 and the ignition device 6 are installed in the combustion chamber. On the chamber 5, the feeder 9 is connected to the balance 10, and then the second compressor 8 is connected to the particle mixer 7. The high-temperature gas generated in the combustion chamber passes through the needle valve 20 and the auxiliary heating pipe 19, and then connected to the plexiglass for testing. One inlet of section 15, the other way of the high-temperature gas produced by combustion chamber 5 and the outlet of particle mixer 7 particles are connected to another inlet of organic glass test section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com