Automatic grouting control device of push bench and method

An automatic control device and pipe jacking machine technology, which is applied in the installation of bolts, shaft equipment, earthwork drilling and mining, etc., can solve the problems of inability to control land subsidence, grout overflow and grouting amount, and long construction period, etc., to achieve Reduce the effect of poor control of grouting volume, reduce working pressure, and avoid ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

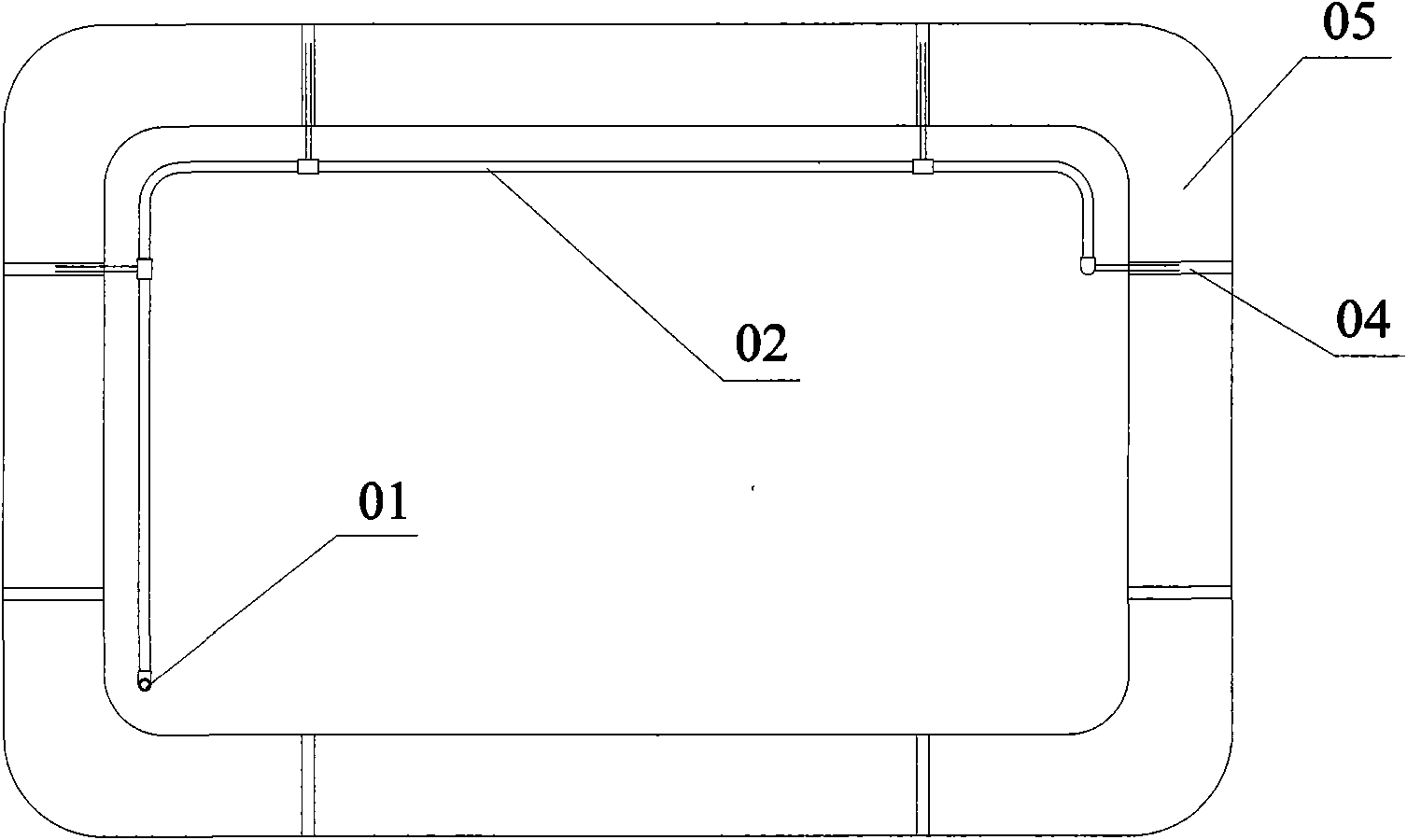

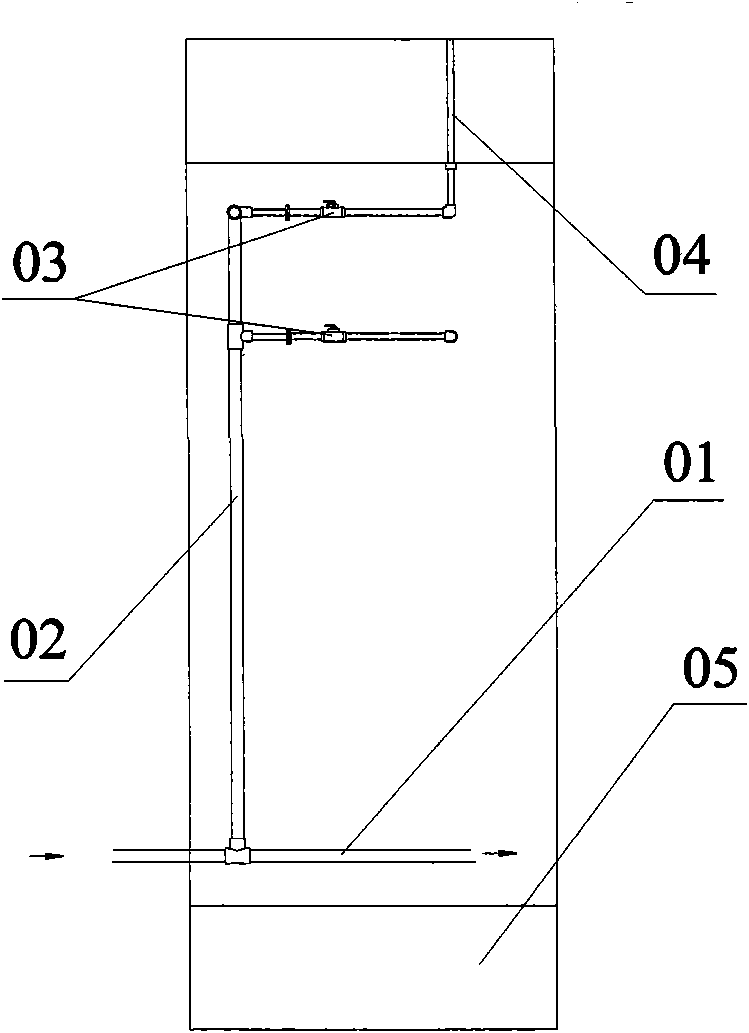

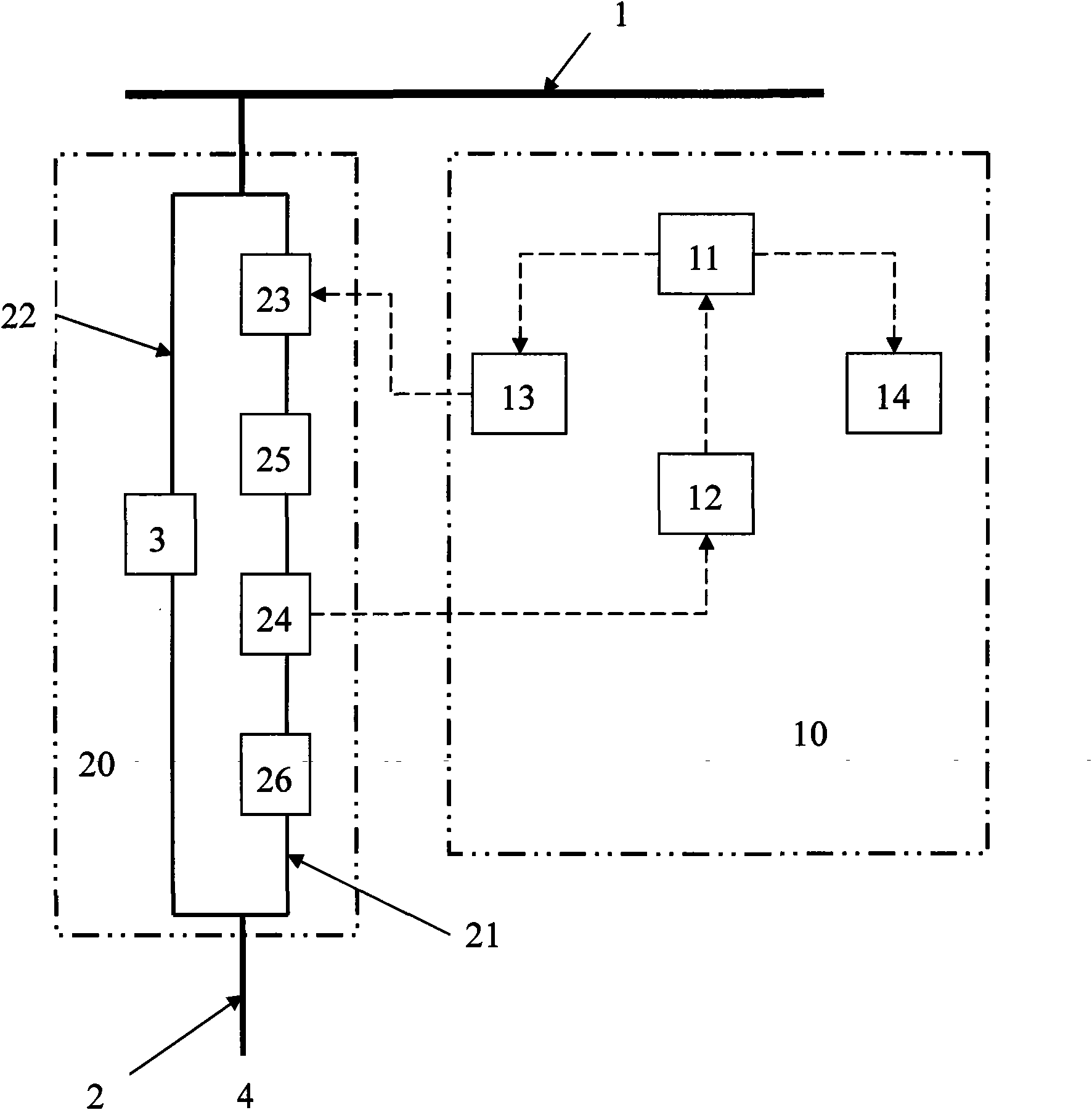

[0032] See first image 3 The structure schematic diagram of the present invention shows that the automatic grouting control device of the pipe jacking machine includes a grouting main pipe 1 connected to the grout storage tank and a grouting pump, a grouting sub-pipe 2 connected to the grouting main pipe, several grouting components 20 and a control Component 10. The grout storage tank and the grouting pump are arranged on the ground (not shown in the figure), and the grouting main pipe 1 leads from the ground to the pipe joints ( image 3 not shown in the figure 1), the grout storage tank is used to store the prepared grouting materials, the grouting pump provides the grouting power of the pipe jacking machine, and the grouting main pipe 1 is the main pipeline for transmitting the grouting materials; at each pipe joint, the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com