Part attribute matrix automatic generation method based on deep learning

An attribute matrix, automatic generation technology, applied in biological neural network model, geometric CAD, design optimization/simulation, etc., can solve problems such as resource consumption and manual operation.

Pending Publication Date: 2020-01-14

深制科技(苏州)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, for the labeling of attribute information, it often requires a lot of manual operation

Moreover, manually marking and assigning the attribute information of parts is a very resource-intensive work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0051] Embodiment 2: On the basis of Embodiment 1, in step eight, multiply the one-hot vector of a given component by the attribute matrix E obtained from training to obtain the attribute vector corresponding to the component. If it is the attribute vector of two parts, it can be applied to related algorithms such as cosine angle, neural network, etc. to calculate their similarity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

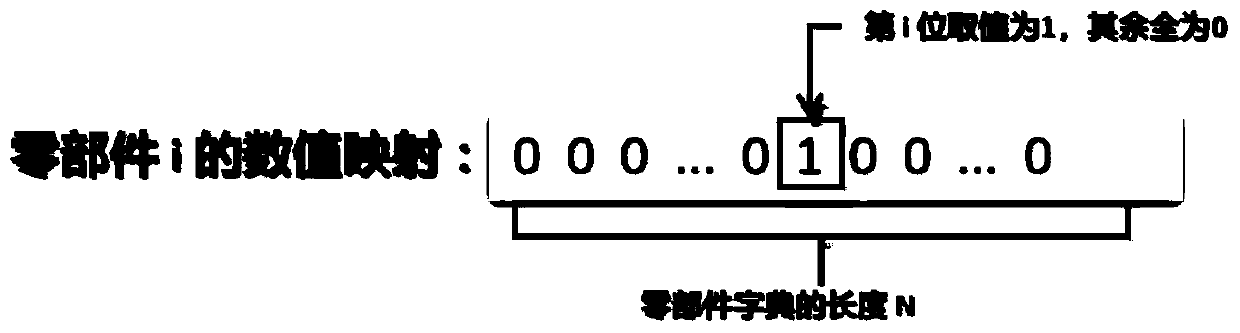

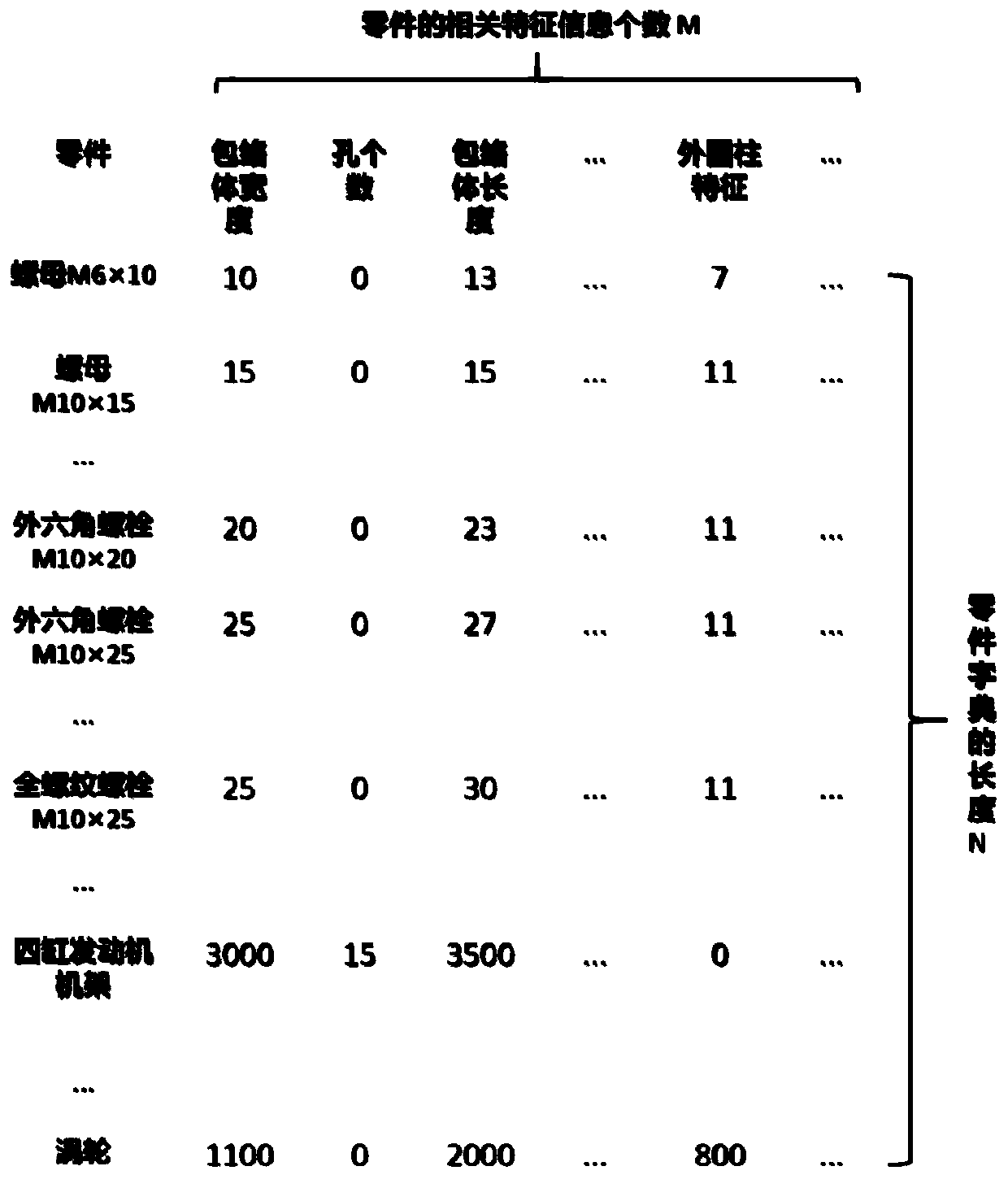

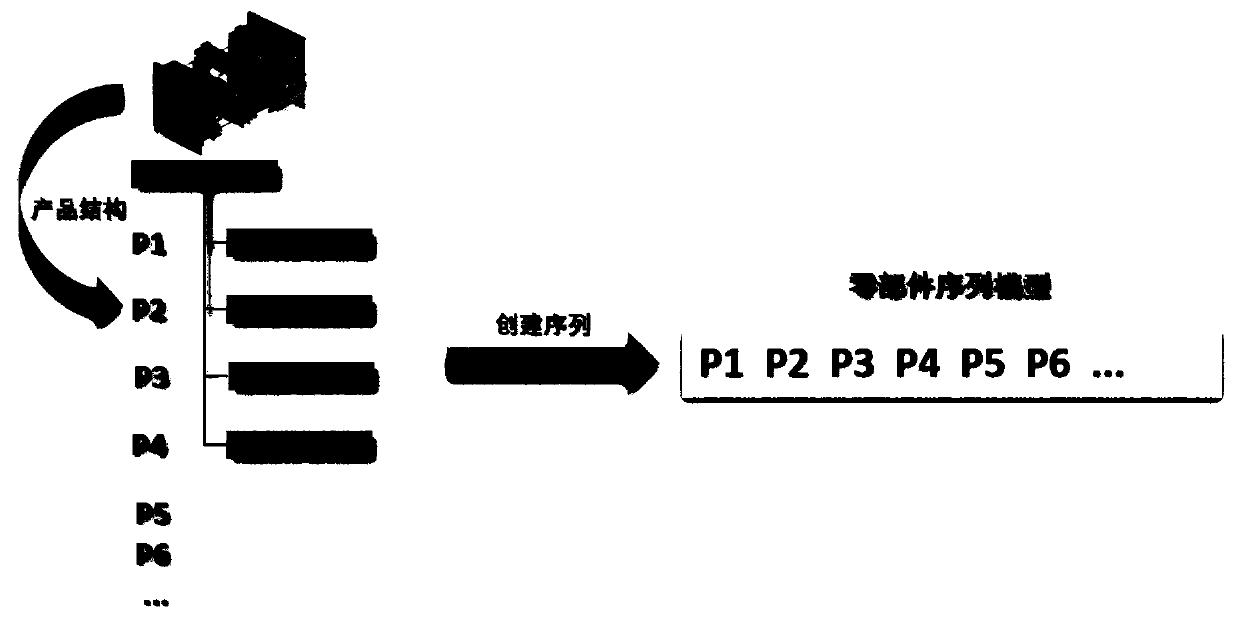

Login to View More Abstract

The invention discloses a part attribute matrix automatic generation method based on deep learning, and the method comprises the following steps: A, obtaining part information of a product serving asa sample, and creating a part dictionary; B, creating numerical mapping of parts; C, defining the size of an attribute matrix E; D, establishing a part sequence model according to the structure of thesample product; E, setting a fixed sliding window, and dividing a part sequence model to form a training sample set D; F, constructing a neural network structure, and determining an input layer, a hidden layer and an output layer of the network; G, training the related samples; and H, using the attribute matrix E. The invention provides a part attribute matrix automatic generation method based ondeep learning. By means of the method, the attribute matrix can be automatically obtained without manually marking a large number of attributes of a large number of components one by one.

Description

technical field [0001] The invention relates to the technical field of intelligent manufacturing, in particular to a method for automatically generating component attribute matrices based on deep learning. Background technique [0002] At present, in the field of intelligent manufacturing, when using data mining or artificial intelligence to analyze parts, it is often easy to lose their relevance. And enhancing the correlation of parts in data mining can be very effective in understanding the similarity between parts. In product design, accurate and effective component similarity calculation can effectively recommend component selection, so it can improve the efficiency of product intelligent design; in processing process design, because it can greatly improve process resources and process parameters, etc. The reusability of process information can greatly improve the efficiency of intelligent processing process design; in the process of assembly process design, because it ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/17G06F30/20G06N3/02

CPCG06N3/02Y02P90/30

Inventor 马腾马佳支含绪邓森洋陈雨晨

Owner 深制科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com