Purifying and spraying device for environmental-friendly treatment of waste gas

A technology of environmental protection treatment and spraying device, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve problems affecting the fluency of filter screen filtration, improve the efficiency of exhaust gas purification, increase the fluency of work, Effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

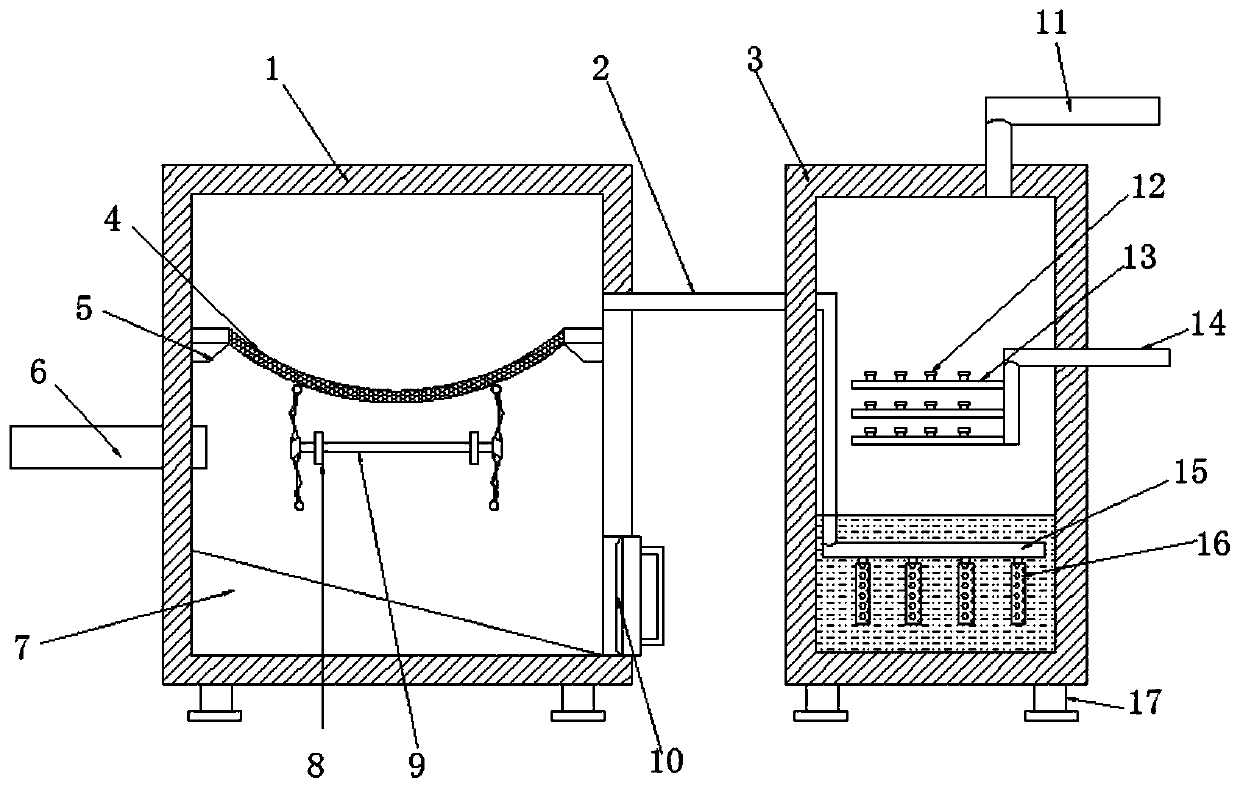

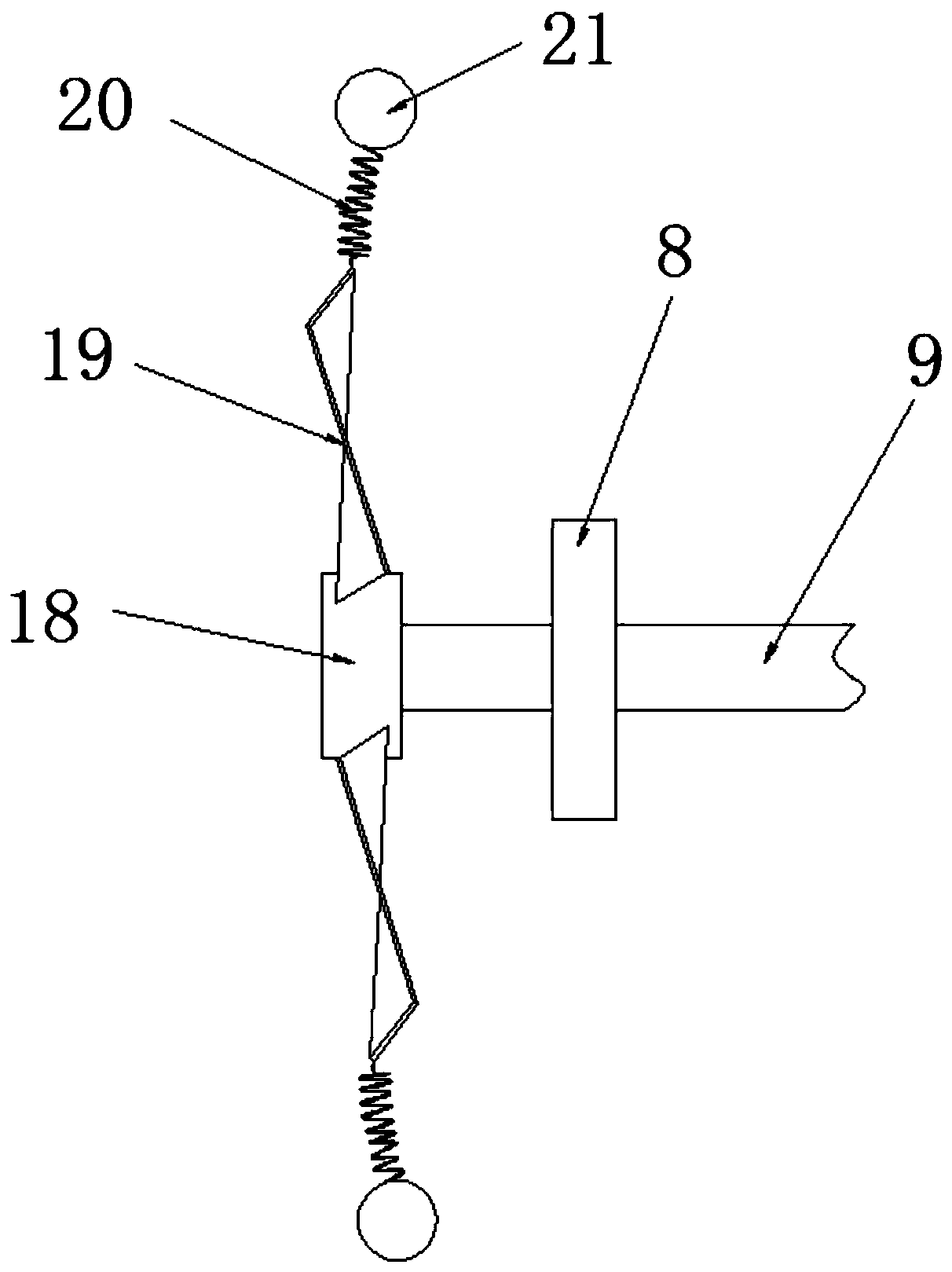

[0028] refer to Figure 1-3 , a purification spray device for waste gas environmental protection treatment, comprising a dust removal box 1 and a spray box 3, a connecting pipe 2 is inserted between the dust removal box 1 and the spray box 3, and connecting pipes are fixed on the inner walls of the opposite sides of the dust removal box 1 Bar 5, the same arc-shaped filter screen 4 is fixed on the two connecting bars 5, and a vibration mechanism is arranged below the filter screen 4. The vibration mechanism includes two connection blocks 8 fixed on the inner wall of the box body 1, and the two connection blocks 8 is rotated and plugged with the same rotating shaft 9, the two ends of the rotating shaft 9 are fixed with a rotating head 18, and a plurality of annularly distributed fan blades 19 are fixed on the outer wall of the rotating head 18, and a spring 20 is fixed on the edge of the fan blade 19. The end of the spring 20 away from the fan blade 19 is fixed with a hollow ste...

Embodiment 2

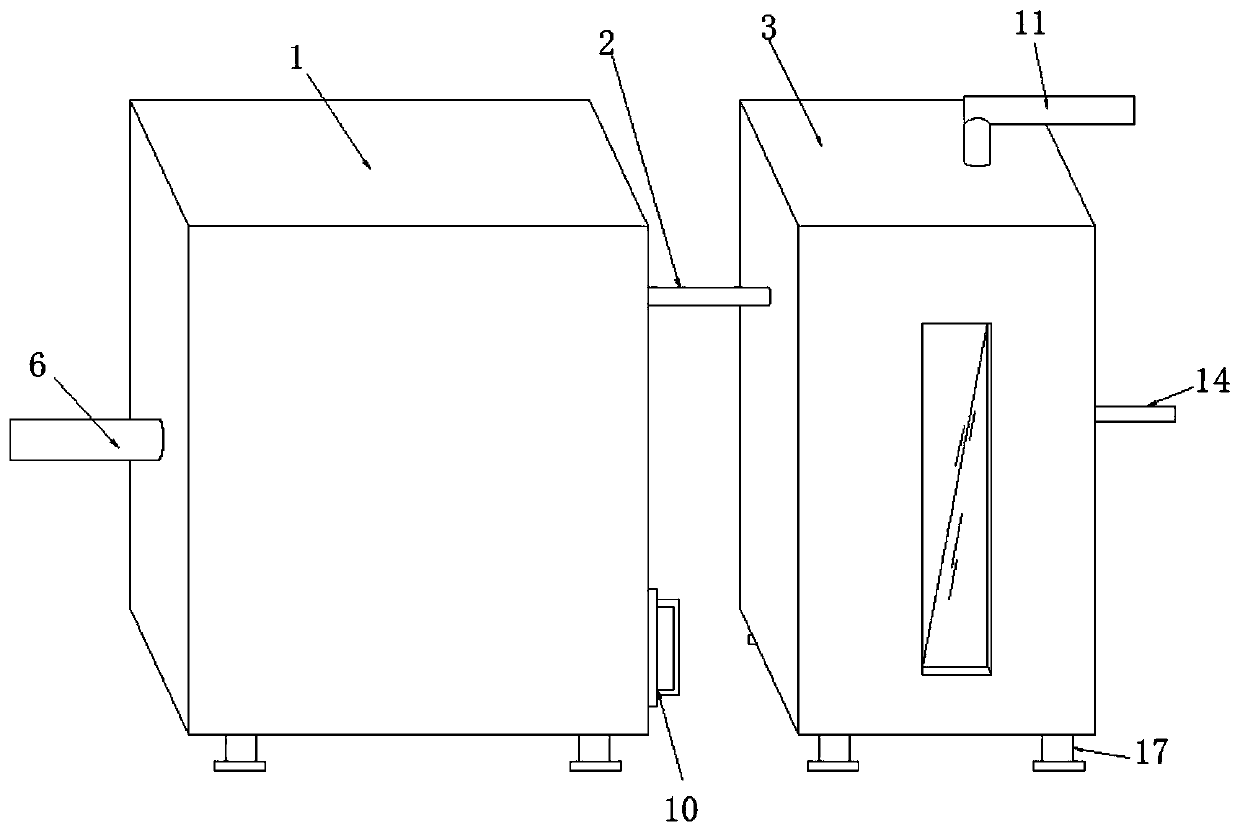

[0038] refer to Figure 4 with Figure 5 , a purification spraying device for waste gas environmental protection treatment. The difference between this embodiment and Embodiment 1 is that there are multiple groups of turbulent flow plates 22 that are staggeredly distributed on the top of the spray box 3, and the end faces of the turbulent flow plates 22 are semicircular arcs. shape.

[0039] The working principle of this embodiment: the gap between the turbulent flow plates 22 can increase the upward movement of the exhaust gas containing water vapor after the purification reaction, and the water vapor molecules collide with the surface of the turbulent flow plates 22 during the upward rising process, and the water molecules gather together to form water droplets Fall into the bottom of the spray box 3 to reduce the moisture content in the exhaust gas.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap