Solid aluminum profile flatness shaping method and shaping device

A shaping device and technology for aluminum profiles, applied in the field of aluminum profiles, can solve the problems of scratching the surface of aluminum profiles, low shaping efficiency, and large shaping workload, and achieve the effect of ensuring shaping effects, simple shaping methods, and good shaping effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

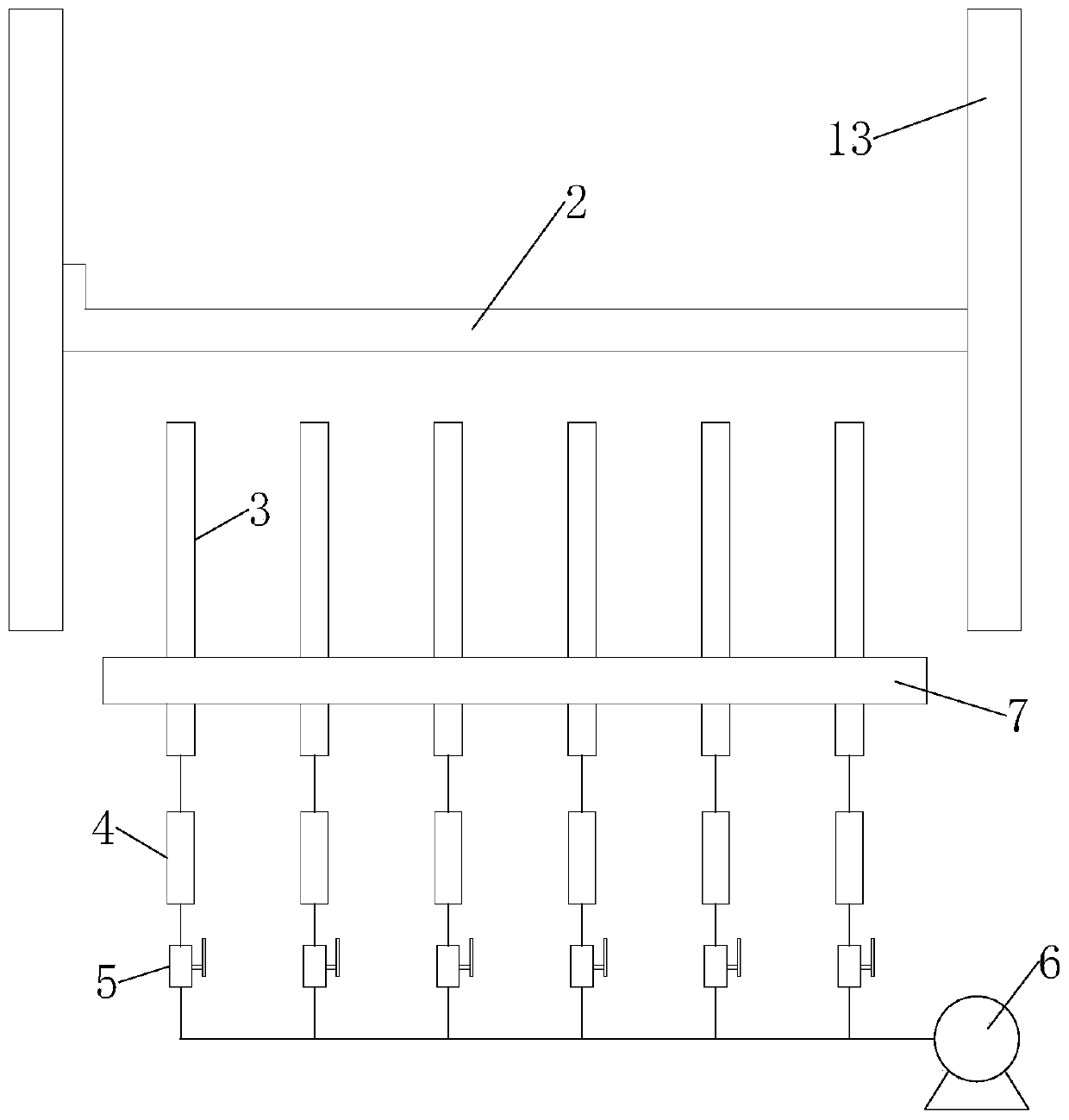

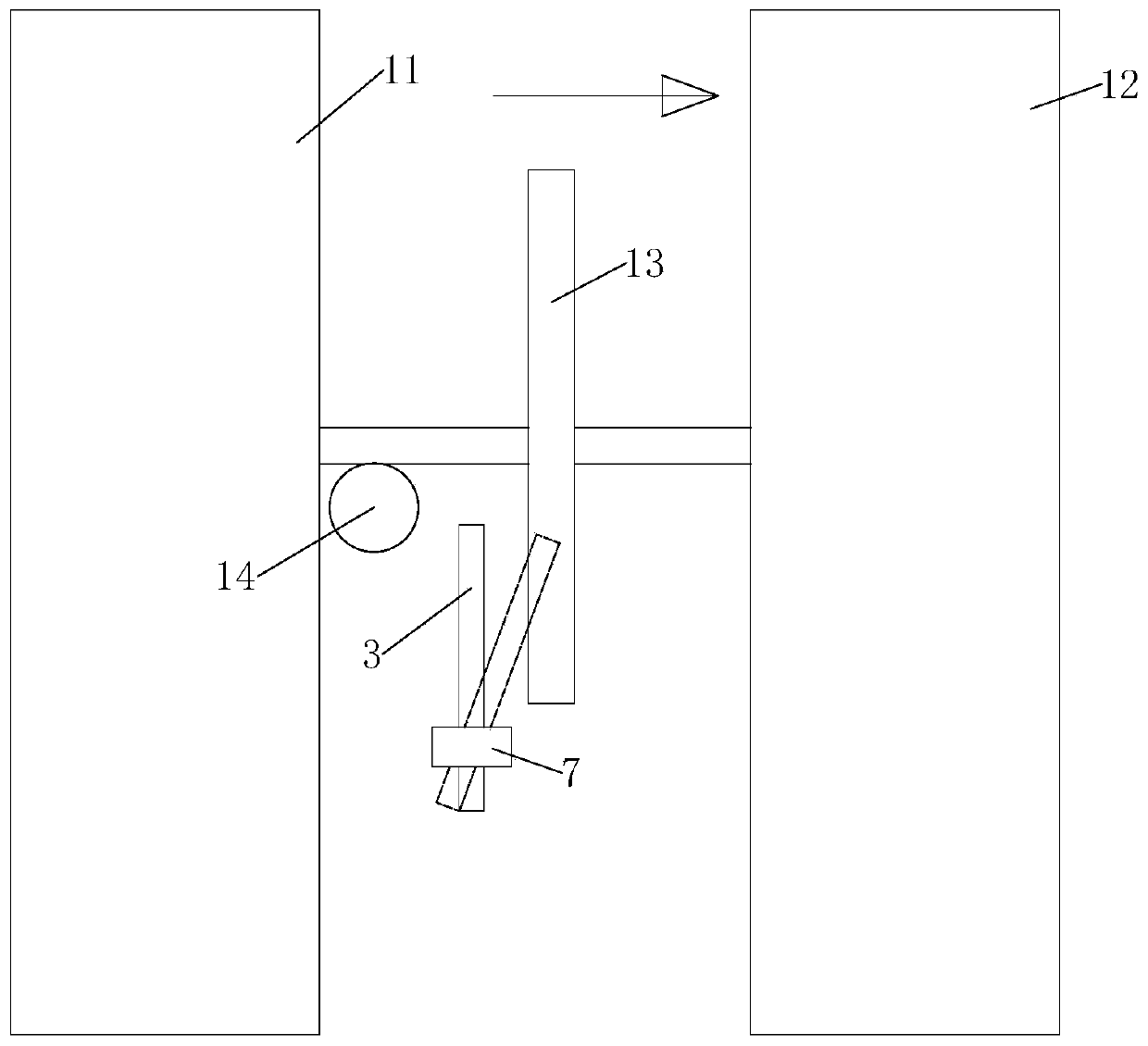

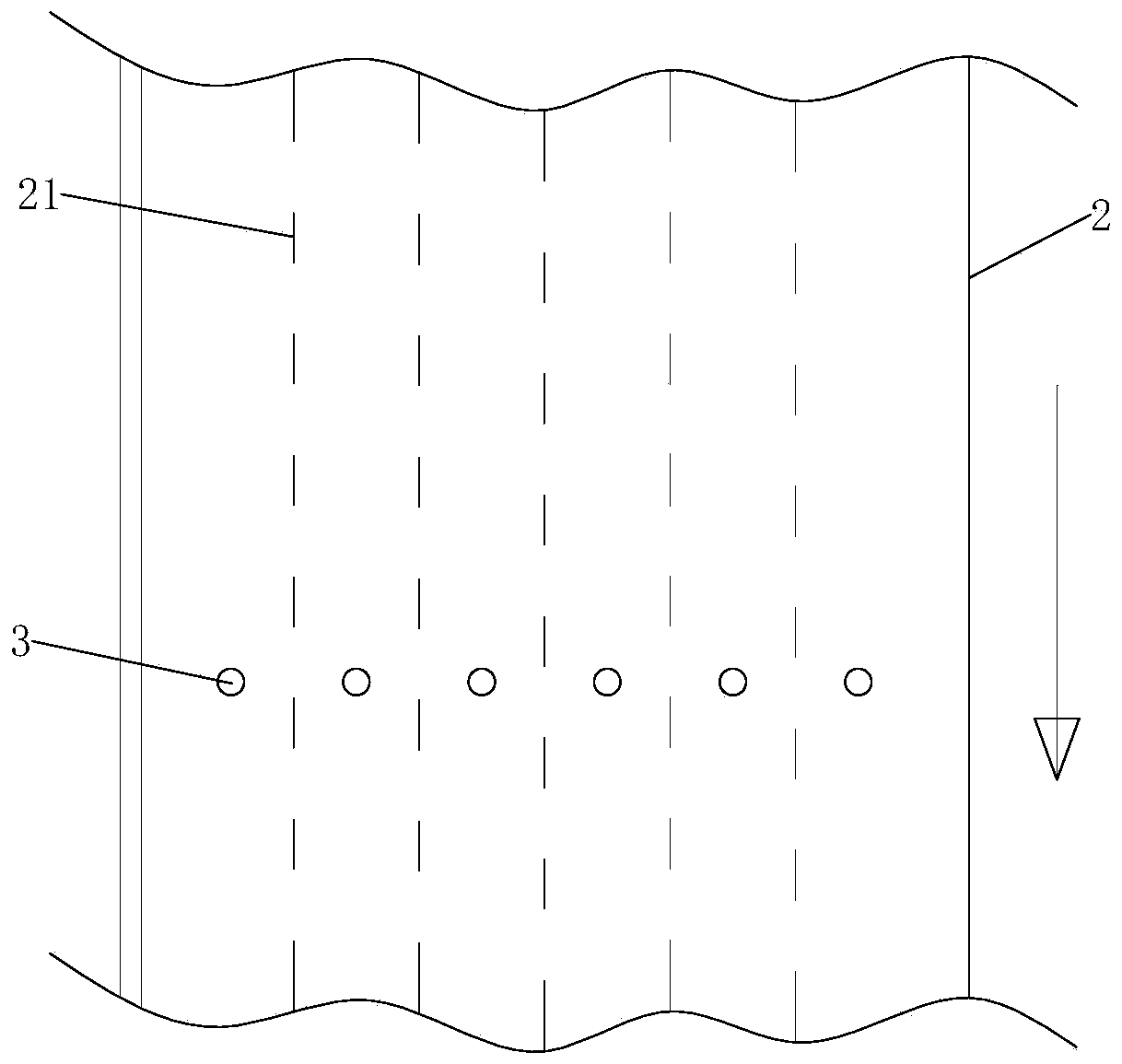

[0038] like Figure 1 to Figure 3 As shown, the solid aluminum profile flatness shaping device includes a water spray pipe 13, and there are no less than two water spray pipes 13. The water spray pipe 13 is located on one side of the flat side of the aluminum profile 2, and the water spray pipe 13 is along the The distribution of the width direction of the flat side of the aluminum profile 2, the water spray pipe 13 is located at the discharge end of the extrusion die 11 of the aluminum profile 2, and the water spray tube 13 is used to spray cooling water onto the flat side of the aluminum profile 2 for partitioned water spray cooling; Valve 4, the number of valve 4 is consistent with the water spray pipe 13, the valve 4 is connected with each water spray pipe 13 respectively, the valve 4 is used to control the switch and flow adjustment of the water spray pipe 13; the water pump 6, the valve 4 are connected with the water pump 6; And cooling water tank, cooling water is house...

Embodiment 2

[0044] On the basis of above-mentioned embodiment one, also comprise float flow meter 4, the quantity of float flow meter 4 is consistent with water spray pipe 13, and float flow meter 4 is installed between water spray pipe 13 and water pump 6, and float flow meter 4 uses To display the flow rate of each water spray pipe 13. The rotameter 4 is used to cooperate with the valve 4 to accurately control the flow, so as to realize high-precision adjustment and improve the accuracy and effect of shaping.

Embodiment 3

[0046] On the basis of the first or second embodiment above, a temperature sensor is installed on the water spray pipe 13, and the temperature sensor is used to detect the temperature of the spray water. The cooling water tank is a constant temperature water tank.

[0047] The temperature sensor can use PT100 or thermocouple to monitor the temperature of the cooling water, so as to avoid the impact of large fluctuations in the temperature of the cooling water on the shaping. The constant temperature water tank ensures stable deformation, reduces the influence of temperature on plastic surgery, improves the stability of plastic surgery, and ensures the plastic surgery effect.

[0048] The constant temperature water tank is an existing technology, and the cooling water sent by the cooling tower can be further cooled by adding refrigeration equipment to ensure that the water temperature entering the water spray pipe 13 is stable.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap