Device and cutting method for semi-automatic cutting of product waste

A semi-automatic, scrap technology, applied in the direction of positioning device, feeding device, clamping, etc., can solve the problems of taking up large production time, uneconomical, and different lengths, and achieve the effect of avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

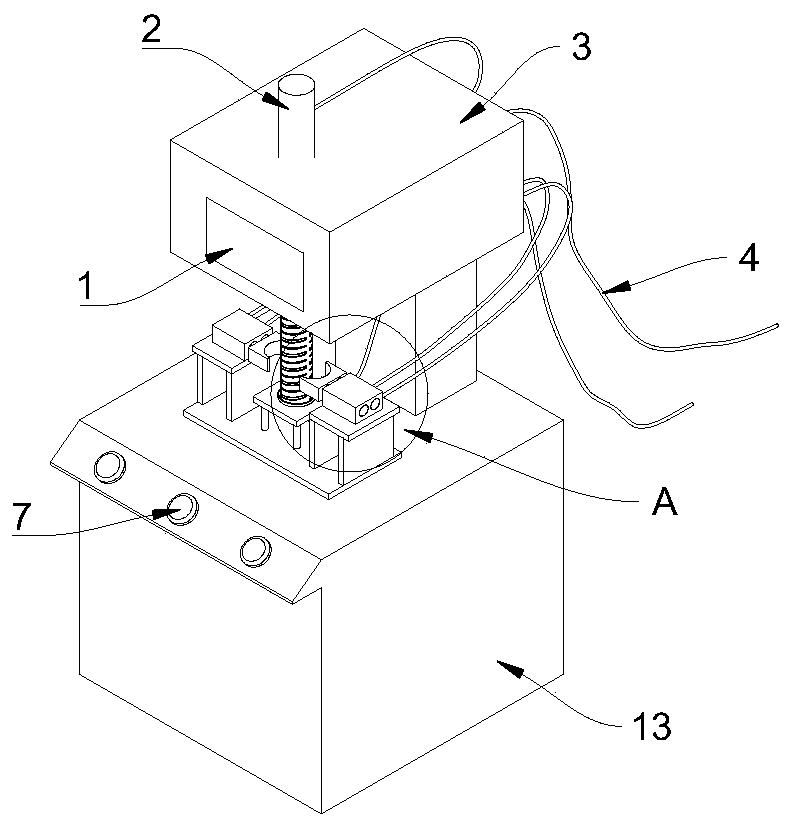

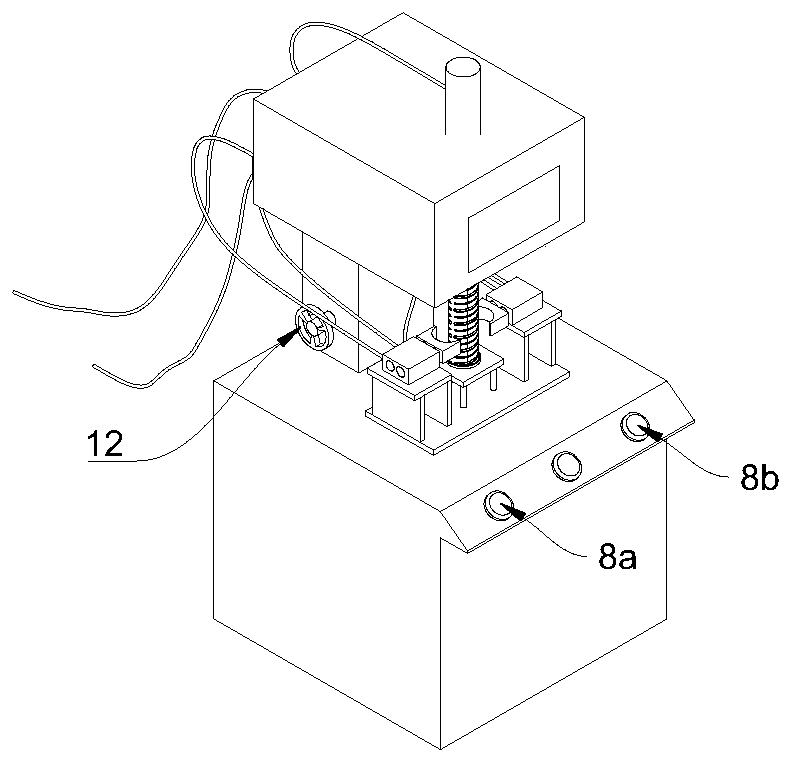

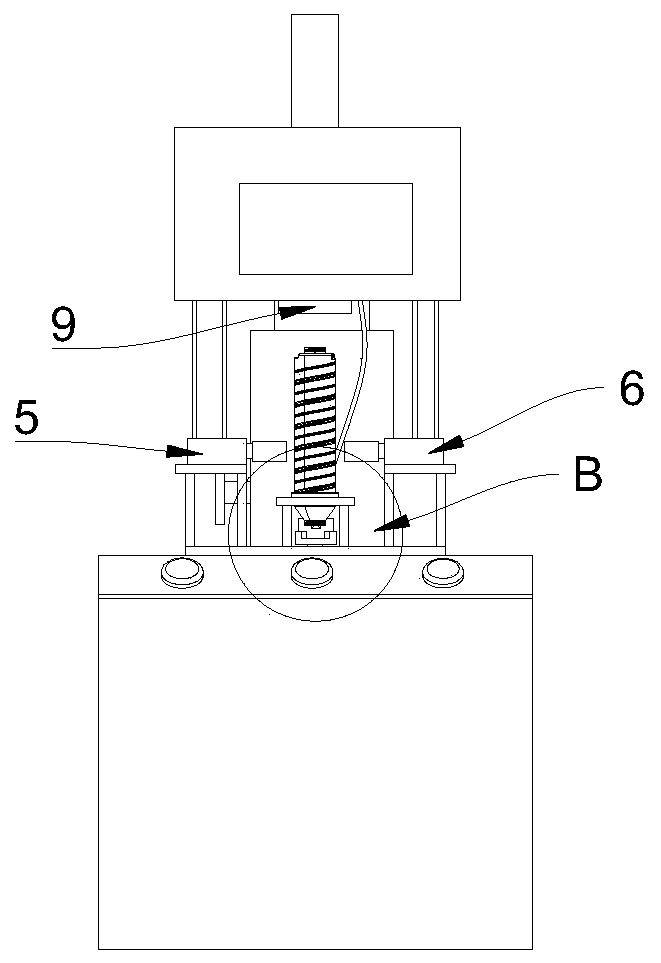

[0024] next combined with Figure 1~5 A specific embodiment of the present invention is described in detail.

[0025] A semi-automatic device for cutting product waste, including a touch screen 1, an oil cylinder 2, a chassis 3, an air pipe 4, a right auxiliary clamp 5, a left auxiliary clamp 6, an emergency stop button 7, an action button 8, a driving head 9, and a lifting mechanism 10 , cutting knife 11, lifting disc 12, fixed platform 13, lower auxiliary clip 14 and fixed frame 15; described cabinet 3 is connected on the fixed platform 13 by elevating mechanism 10, and elevating mechanism 10 is carried out by the elevating plate 12 that its side is provided with Lifting adjustment, described lifting mechanism is prior art, and the inventive point of the present invention does not lie in this, so do not elaborate.

[0026] The cabinet 3 is the control component of the present invention, with a built-in control module and pneumatic pipelines. The side of the cabinet 3 facing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com