Centerless super-fine grinding and polishing processing device for precise shaft parts

A technology of processing device and precision shaft, applied in the direction of ultra-finishing machine, metal processing equipment, manufacturing tools, etc., can solve the problems of large coaxial error of shaft parts, increase of geometric shape error, bending deformation of shaft parts, etc. The effect of small coaxiality error, reduced deformation, and improved geometrical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

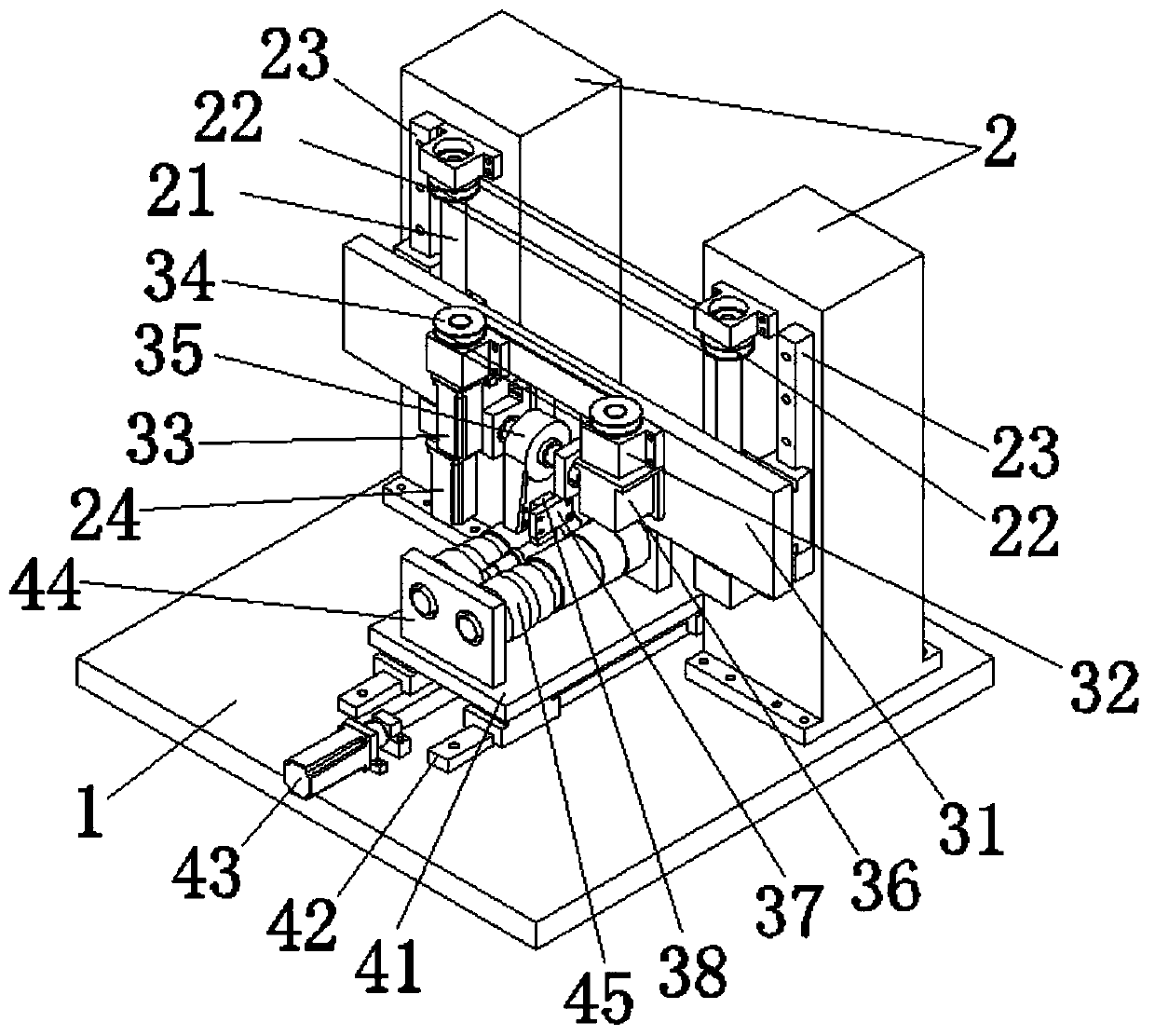

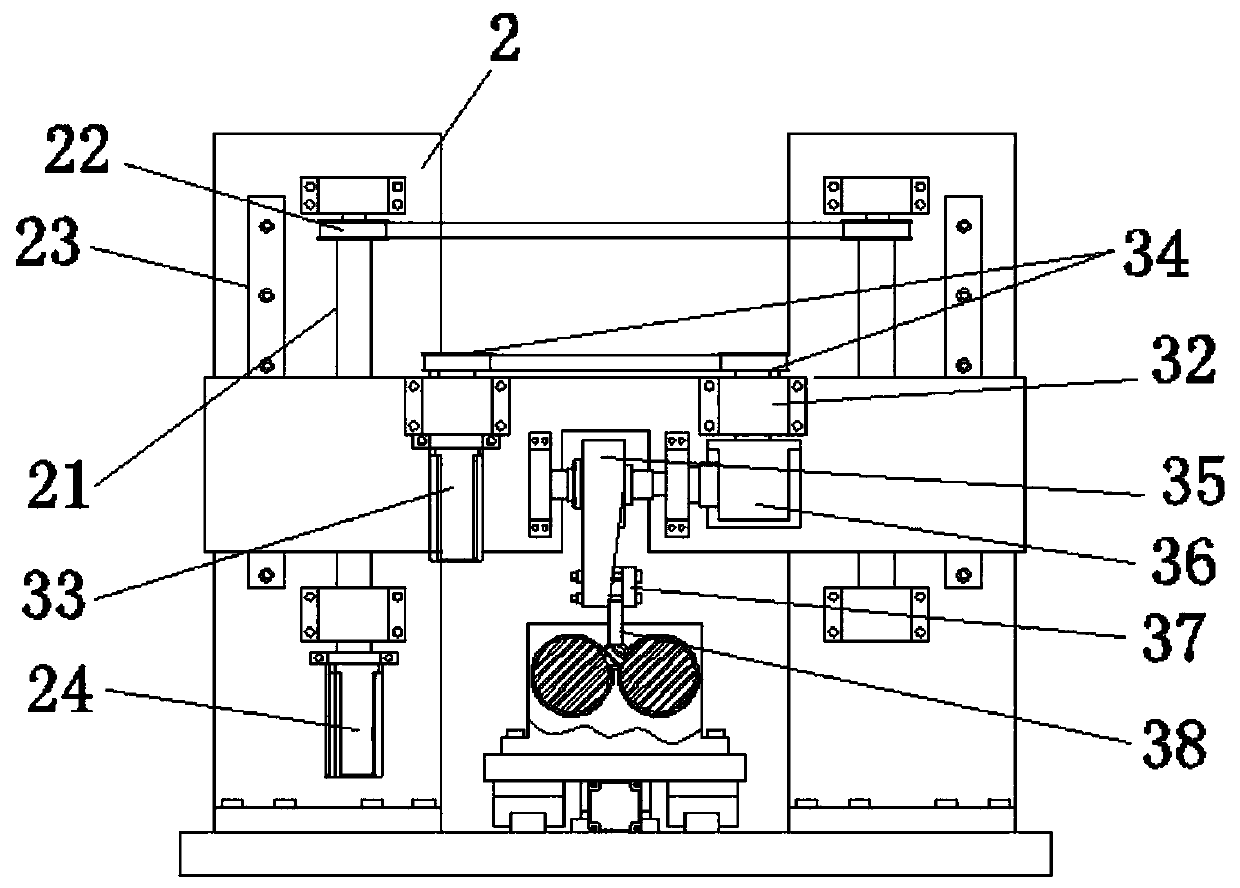

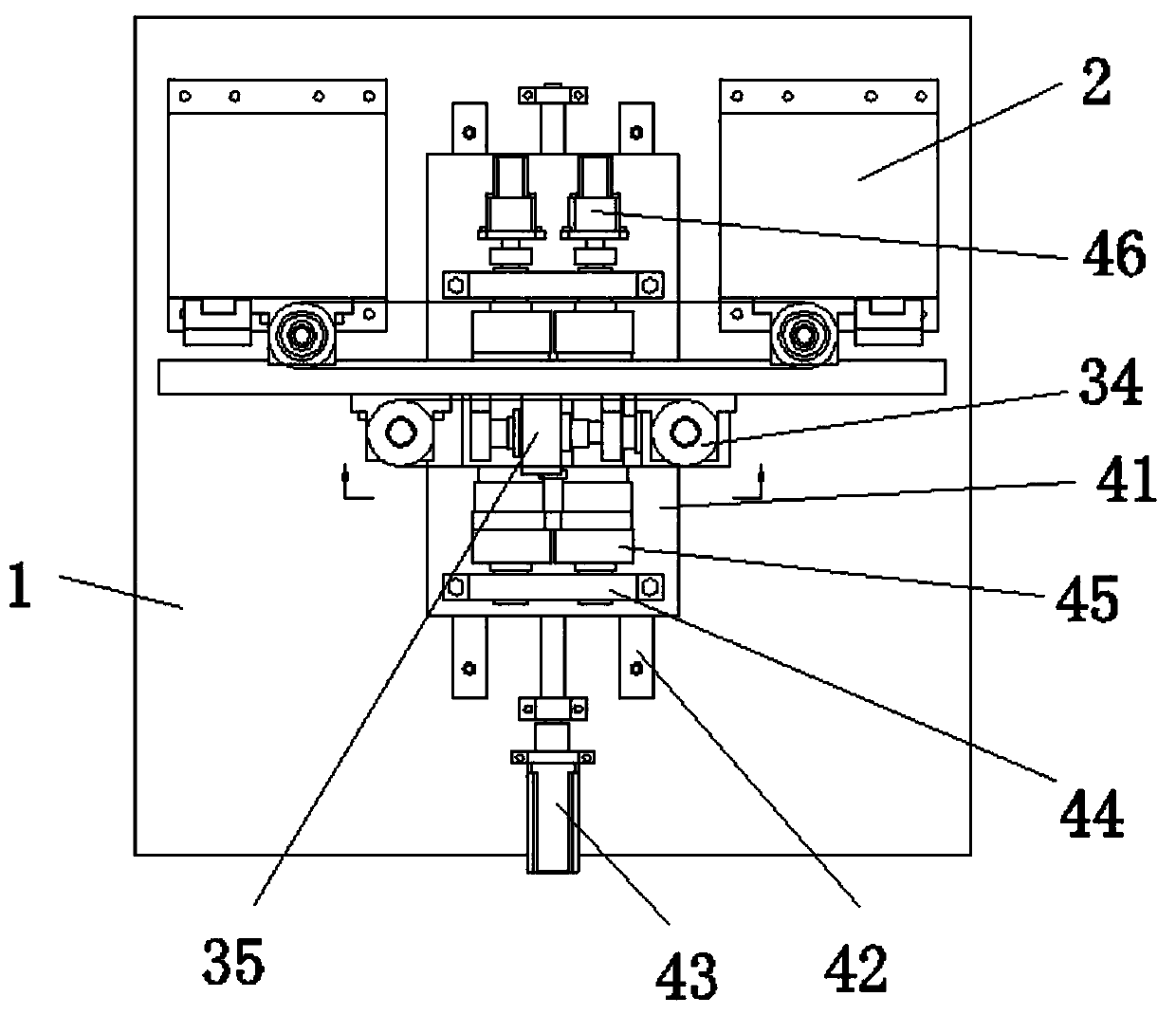

[0020] see Figure 1-Figure 3 , a centerless ultra-fine grinding and polishing processing device for precision shaft parts, comprising a base 1 and a column 2, the column 2 is fixedly mounted on the top plane of the base 1, and a horizontal movement mechanism is installed on the top plane of the base 1, A guide roller rotation drive mechanism is installed on the top plane of the horizontal moving mechanism, a grinding head lifting mechanism is fixed on one end surface of the column 2, and a grinding head tilting mechanism is installed on the outer plane of the beam of the grinding head lifting mechanism, and the grinding head tilts. The output end of the pendulum mechanism is equipped with a grinding and polishing processing device. The rotating drive mechanism of the guide roller supports the bottom end of the precision shaft parts, and the grinding head lifting mechanism squeezes the top of the precision shaft parts, thereby determining the spatial position of the precision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com